Qingdao National Premium Oilwell Machinery Co.,Ltd |

|

All our fluid end parts are manufactured to API 7K quality standards.

Parts are available for these popular pump models:

BOMCO/Emsco Mud Pumps:F2200HL, F1600HL, F-1300, F-1600, FB1300, FB1600, F-800, F-1000, F-500, F-350, DB-550, DA-700, FA-1600/1300, FC-2200, D-300/500, D-375, D-700,

LS National Mud Pumps: 3NB-500C, 3NB1000C, 3NB1300C, 3NB1600

Ideco Mud Pumps: T-500, T-800, T-1000, T-1300, T-1600,

National Mud Pumps: 7P50, 8P80, 9P100, 10P130, 12P160, N1300, C-250, K-700, 14-P-220,

E-700/G-1000, K-500, K-380, K-500A/700A, C-250/350, JWS-400,

Gardner Denver Mud Pumps: PZ7, PZ8/9, PZ10/11, FK-FXK, FY-FXD, FD-FXX, FG-GXG, FG-FXG,

KG-KXG, FQ-FXQ, FF-FXF, FF-FXP,

Oilwell Mud Pumps: A-560/600-PT, A-850-PT/A-1100-PT, A-1700-PT/A-1400-PT

Wirth Mud Pump: TPK1000, TPK1600, TPK 2000,TPK2200

Russian Mud Pumps: UNBT-950, UNB-600, 8T-650, UNBT650, NBT600, UNB1180, UNB1180L, NB125, NB80, NB50, NB32

WEATHERFORD/Ellis Williams: E-447, E-2200

Drillmec Mud Pump: 9T1000, 12T1600, 7TS600, 7TS500, 9T800

Romania Mud Pump: 3PN-1000, 3PN-1600, 3PN-2000

And other brand spare parts for WIRTH, OPI, Ellis Williams, Wilson, Gaso, Skytop/Brewster.

|

Baoji Oilfield Machinery Co., Ltd. (BOMCO) is a leading research & development manufacturing enterprise, affiliated to China National Petroleum Corporation (CNPC), for oil drilling and production equipments, land drilling rigs, F-series mud pumps, multi-purpose wirelines and drilling rig power control system.

The principal products of BOMCO also include F-series mud pump ranging from 500 HP to 3,000HP, well control and well head equipments, special vehicles, steep pipe, wireline, large size roller bit, power control system, and non-conventional oil and gas equipments.

| Triplex Mud Pumps Manufacturers and Brands | |||

| NATIONAL mud pump | GD mud pump | EMSCO mud pump | OILWELL mud pump |

| 7P50 | PAH-275 | F350/500/650 | A350PT |

| 8P80 | PZ-7 | F800 | A560/600PT |

| 9P100 | PZ-8 | F1000 | A850PT |

| 10P130 | PZ-9 | FB1300 | A100PT |

| 12P160 | PZ-10 | FB1600 | A1400PT |

| 14P220 | PZ-11 | FC2200 | A1700PT |

| IDECO mud pump | DRILLMEC mud pump | WEATHERFORD mud pump | BOMCO mud pump |

| T500 | 7TS500 | MP-5 | F500 |

| T800 | 9T800 | MP-8 | F800/F1000 |

| T1000 | 9T1000 | MP-10 | F1300 |

| T1300 | 12T1600 | MP-13/16 | F1600 |

| T1600 | 14T2200 | E-447 | F1600HL |

| E-2200 | F2200HL | ||

| TSC mud pump | EWCO mud pump | AMERICAN BLOCK mud pump | EWECO mud pump |

| WF-400 | W-440 | K-800 | E-447 |

| WF-700 | W-446 | K-1000 | E-600 |

| WF-1300 | WH-1312 | K-1300 | E-800 |

| WF-1600 | WH-1612 | K-1600 | E-1100 |

| WF-2000 | W-1712 | E-1300 | |

| WF-2200 | W-2214/W-2215 | E-1600 | |

| HONGHUA mud pump | LS NOV mud pump | WIRTH mud pump | Rongsheng mud pump |

| F500 | 3NB500C | TPK-1000 | W440/446 |

| F800 | 3NB800C | TPK-1600 | F500 |

| F1000 | 3NB1000C | TPK-2000 | F800 |

| F1300 | 3NB1300C | TPK-2200 | F1000 |

| F1600 | 3NB1600 | F1600L | |

| F1600HL/F2200HL | F-1600/F-1600L | ||

| Other Mud pumps and Parts brands: Southwest, Mud King, Baker, Texma, Skytop, RG, Ellis Williams, Brewster | |||

| Disclaimer:National Premium Oilwell Machinery Co.,Ltd is in no way affiliated with any of the reference manufacturers and company names and Brands and /or part numbers are for reference purposes only. | |||

| Duplex/Well Services Mud Pumps Manufacturers and Brands | |||

| Emsco | National | Oilwell | Ideco |

| D300 | N1000-1600 | 6P-HD | MM300 |

| D500 | K380 | 8P-HD | MM500/500F |

| D550 | K500 | 610P | MM700/700F |

| D700 | K500A | 212P | MM600/600F |

| D375 | K700A | 214P/14P | MM200 |

| C150/C150B | 218P | MM300 | |

| C250 | 18P | ||

| Gaso | Gardner Denver | Gardner Denver | Ellis Williams |

| 1563 | 5" x 6" FG FXG | 7.5” x 8” FY FXX | 15W600 |

| 1740-55 | 5" x 8" FD FXX | 7.25" x 12" FZ FXZ | 19W1000 |

| 2651 | 5.5" x 8" FD FXX | 7.25" x 14" FXN | |

| 2652 | FC-FXX/FC-FXD | 7.25" x 14" FK FXK | |

| 5" x 10" FD FXD | FQ-FXQ | ||

| 5.5" x 10" FD FXD | 7.25" x 10" FO FXO | ||

| 7.5" x 10" FY FXD | 4.5" x 6" FG FXG | ||

| Drillmec | Russian | Gardner Denver | |

| 10D2C | NB125 | 4x5 TEE Triplex | |

| 8D1S | NB80 | 5-1/2x5 THE Triplex | |

| NB50 | 5x8 PAH Triplex | ||

| NB32 | PJ-8 | ||

| The Spares for Above pumps: | |||

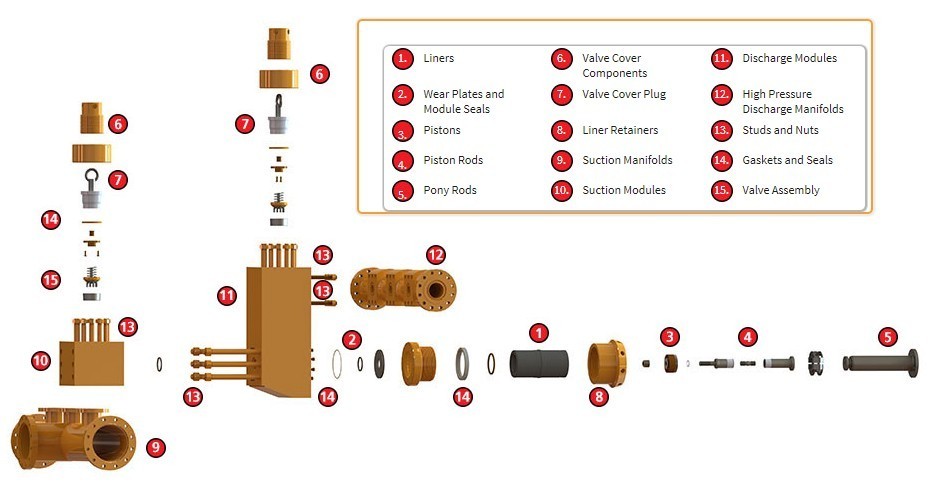

| * Liners | |||

| *Pistons | |||

| *Piston Rubber kits | |||

| *Piston rods | |||

| *Valves & Seats | |||

| Disclaimer:National Premium Oilwell Machinery Co.,Ltd is in no way affiliated with any of the reference manufacturers and company names and Brands and /or part numbers are for reference purposes only. | |||

Mud Pump Liners

Premium manufactures chrome alloy sleeved liners, hardened liners, hardened / chrome plated liners and Zirconia liners. Premium also supplies genuine U.S. made rubber and urethane liner seals. All our liner products are exchangeable with OEM products and meet or exceed API-7K standards.

All our liners are made with a high strength forged steel shell machined to fit triplex pumps and fitted with high pressure lip sleeve. The liner is precision machined to exact tolerances to keep the liner concentric. The sleeve is manufactured to the bore tolerances specified by API to provide longer life by reducing gaps between the liner bore and piston.

Premium's zirconia liner offers life time cost savings, significantly longer service, better performance and safer operation than those made of more commonly used alumina ceramic. Premium's zirconia liner is a proprietary Zirconium-based matrix that has significantly improved mechanical characteristics.

◎ Zirconia has three important property advantages compared to alumina.

◎ Zirconia exhibits better impact strength.

◎ Zirconia is harder than alumina.

◎ Zirconia can be honed to finer surface finishes than alumina. Finished to 4 RMS,

◎Zirconia liners - provide a surface finish that's three to four times finer than alumina.

All three of these property advantages translate to lower ownership costs. The improved wear directly extends the service life of the sleeve, while the improved impact strength cuts down on the significant costs of replacing broken liners in the field. The surface finish improvements, meanwhile, have an indirect effect.

◎ HP design with shoulder-on-hull design to prevent sleeve slippage

◎ Reduced liner and piston wear

◎ Rated for all drilling operations up to 7500 PSI

◎ Bore hardness of 92-94 Rockwell

◎ ID tolerances of +.010”/ -.000”

◎ Surface finish of 4 - 8 RMS

◎ Hardness i s HV 0.3 kg/mm – 1100/1200 ( 92 - 94 Rc)

◎ High pressure design to prevent slippage

◎ Liner sizes are available from 4½” to 7” for all popular mud pump

Zirconia Liner Sleeve

Chemistry and Mechanical Properties

| Material Chemistry | >99.5% ZrO2 + HfO2 + Y2O3 |

| Density (g/cm3) | >5.95 |

| Hardness (Vickers) | 1200 (Est.) |

| Fracture Toughness (MPa.m1/2) | 10‐15 |

| Coefficient of Thermal Expansion | 9.6 |

| Bending Strength (Mpa) | 600‐800 |

| Modulus of Elasticity (Gpa) | 200 |

| Thermal Conductivity (W/m.k) | 450 |

| Crystalline Grain Size (um) | <1 |

| Acid and Alkali Resistance (Regular Temp.) | Best |

What is Zirconia?

• Its great hardness, low reactivity, and high melting point have

made it the oldest mineral that can be found on earth.

• Zirconium Dioxide (ZrO 2 ), also known as zirconia is a white crystalline oxide of the element zirconium (Zr).

• Exists naturally as the mineral Baddeleyite.

• One of the most studied ceramic materials.

Zirconia Case Study

→ Conducted four year case study and collected over 12,000 pumping hours

→ Pumps using Chromium Liners had expendable cost of $47,000 vs. $11,000 for Zirconia Liners

→Pump shutdowns were 4x higher (8 vs. 32) in chromium pumps compared to Zirconia

→ Zirconia lined pumps used approximately 1/5 of the pistons compared to chromium lined pumps

Zirconia Benefits

→ Ceramic Liners out perform steel Liners

→ Zirconia is significantly stronger and tougher than Alumina in bending or tension, often by a factor of 4 or more

→ Does not require self aligning piston rods

→ Extended Life and less wear reduces overall expendable cost

→ Traditional liner hourly cost is approximately $1.05 per hour, while Zirconia Liners are approximately $.23 per Hour

The outer hull, or body, of the liner is a high strength forging. Premium uses forgings exclusively to ensure the consistent quality. The sleeve is centrifugally cast in the Premium facilities by skilled craftsmen. It has the maximum amount of chrome for the base metal and Premium adds molybdenum to

increase the hardness depth. The sleeve is then inserted into the hull at a tightness that exceeds its counterparts. The liner is rated to match the pressure rating of the pump per liner size.

- High Strength forged steel outer hull.

· - High Chrome alloy inner sleeve honed to mirror-like finishes.

- Rated for all drilling operations up to 5,000 PSI and 7500 PSI

- Bore hardness is 62 - 69 Rockwell

- HP design to prevent inner sleeve slippage

- Extremely long service life

Premium chrome plates the same outer hull in lieu of sleeve to a maximum thickness. It is then machined and polished to a mirror finish.

Features:

• Single high strength forged steel hull construction.

• Optional chrome plating to reach hardness of 62 RC. Corrosion resistance, free deformation.

Hardened Liner

Premium’s Hardened Liner the same outer hull in lieu of sleeve to a maximum thickness. It is then machined and polished to a mirror finish.

Features:

• Single high strength forged steel hull construction.

• Inner bore is nitro carburized and quenched to reach hardness of 60 RC.

• Corrosion resistance, free deformation.

Premium can make the following brand pump Chrome-Plated and Hardened liners and more:

| Emsco | National | Oilwell | Ideco |

| D300 | N1000-1600 | 6P-HD | MM300 |

| D500 | K380 | 8P-HD | MM500/500F |

| D550 | K500 | 610P | MM700/700F |

| D700 | K500A | 212P | MM600/600F |

| D375 | K700A | 214P/14P | MM200 |

| C150/C150B | 218P | MM300 | |

| C250 | 18P | ||

| Gaso | Gardner Denver | Gardner Denver | Ellis Williams |

| 1563 | 5" x 6" FG FXG | 7.5” x 8” FY FXX | 15W600 |

| 1740-55 | 5" x 8" FD FXX | 7.25" x 12" FZ FXZ | 19W1000 |

| 2651 | 5.5" x 8" FD FXX | 7.25" x 14" FXN | |

| 2652 | FC-FXX/FC-FXD | 7.25" x 14" FK FXK | |

| 5" x 10" FD FXD | FQ-FXQ | ||

| 5.5" x 10" FD FXD | 7.25" x 10" FO FXO | ||

| 7.5" x 10" FY FXD | 4.5" x 6" FG FXG | ||

| Drillmec | Russian | Gardner Denver | |

| 10D2C | NB125 | 4x5 TEE Triplex | |

| 8D1S | NB80 | 5-1/2x5 THE Triplex | |

| NB50 | 5x8 PAH Triplex | ||

| NB32 | PJ-8 |

![]()

Mud Pump Pistons

Premium’s Pistons are made to precise tolerances and include a variety of materials yielding extended service life. Piston materials include the following from 3” to 7-1/2” sizes to accommodate for all types of drilling conditions, mud properties and temperatures reaching up to 350°F.

Premium provides a full range of mud pump pistons for both triplex and duplex pumps. They are:

- High Temperature Bonded Piston

- Replaceable Rubber Piston

- Long Life Urethane

- Bonded Piston

- Bull Nose Piston

Features:

- Rated for all drilling

- Operations High tensile strength

- Maximum operating temperature is 350°F

- High pressure mud pump

- Service Extended service life

These pistons are constructed of urethane, bonded to a solid metal hub. Double durometer urethane is designed to provide optimum performance in oil base or water base mud and high drilling pressures.

Features:

- Rated for all drilling operations

- Maximum operating temperature is 120˚C

- High pressure mud pump service

- Extended service

Premium's replaceable rubber pistons are made with nitrile rubber to resist extrusion and abrasion. These pistons are fully interchangeable with most other manufactures products. Available sizes are from 3″ through 7½″ and series are A, B, K and L. If flange is not worn past these marks, rubber kit can be installed Fabric anti-extrusion device reduces extrusion of the rubber even at maximum pressure rating

Features:

- High tensile strength

- Rated for all drilling operations

- Maximum operating temperature is 160˚C

- Extended service life

The Green Duo piston is a bonded dual durometer piston that is highly resistant to abrasion and tear. The bonded construction resists extrusion under pressure and restricts movement to reduce the build-up of heat.

The Green Duo piston is recommended for systems with oil or synthetic based mud. It is also recommended for water based muds when weights are 11 lb/gal or over. The Green Duo piston is not recommended for clear water or seawater pumping due to the lack of lubricity of these fluids. As in all urethane pistons, the backflush requirement is recommended at 14 gal/min or greater for each piston.

Features:

-Temperature resistance up to 120˚C

-Can be operated in pressures up to 6300 psi

-Backflush requirement is 14 gal/min or greater for each piston

-Not recommended for clear water or seawater pumping due to lack of lubricity of these fluids

Super premium bonded polyurethane piston designed for operation in extreme drilling environments.

The Blue Lightning piston is manufactured from an engineered elastomeric compound that delivers excellent resistance to tear, abrasion and extrusion while maintaining high mechanical properties. A unique anti-extrusion feature, coupled with a premium elastomer, improves service life while

reducing downtime and allowing for reduced pump maintenance.

Anti-Extrusion Feature

The anti-extrusion feature is a significant feature of the Blue Lightning. Manufactured from a proprietary bearing material that expands upon installation, this feature reduces friction by reducing

or eliminating contact between the steel piston body and the liner wall. Additional benefits include reduced extrusion of the urethane and dramatically increased run times, even in pressures above 5000 psi. The bearing even reduces liner wear and liner damage over other piston designs. The Blue Lightning can be operated in pressures of up to 7500 psi.

Super premium bonded polyurethane piston designed for operation in extreme drilling environments.

The White Lightning bonded piston is manufactured from an engineered elastomeric compound that delivers excellent resistance to tear, abrasion, chemical attack and extrusion while maintaining high mechanical properties.

Temperature resistance up to 140˚C

Increased abrasion and particle embedment resistance

| MISSION "L" MODULE FOR BOMCO F1600 7500 PSI SWOP VERSION | QTY PER PUMP | |||

| FLUID END MODULE & ACCESSORIES | ||||

| ITEM # | SW PART # | MISSION PART # | DESCRIPTION | |

| 8404-25A | FLUID END MODULE COMPLETE ASSEMBLY (INCLUDES ITEMS) | 3 | ||

| 1 | 8404-26 | MODULE, SUCTION STUDDED (INCLUDES ITEMS 1, 7-8) | 3 | |

| 2 | 8404-27 | MODULE, DISCHARGE STUDDED (INCLUDES ITEMS 2-9) | 3 | |

| 3 | 4019-61 | STUD, DISCHARGE TO SUCTION MODULE | 18 | |

| 4 | 1-3/4-8 HH | 6300281 | NUT, DISCHARGE TO SUCTION STUD | 18 |

| 5 | 4017-33 | STUD, POWER END | 30 | |

| 6 | 1-1/2-8 HH | 0-7601-0630-28 | NUT, POWER END STUD | 30 |

| 7 | Feb-15 | OWA17TRSSW | STUD, THREADED RING | 72 |

| 8 | 1-1/4-7 HH | 6300200 | NUT, THREADED RING STUD | 72 |

| 9 | 8488/5/1- | 6511416 | PIN, DOWELL | 6 |

| 10 | 4019-51 | 7006444 | CAPSCREW, LINER RETAINER FLANGE 3/4-10X3 | 18 |

| 11 | 8490-28 | PLATE, LINER WEAR | 3 | |

| 12 | 2988 | 1290344 | GASKET, WEAR PLATE AND MODULE - RUBBER (SEE DATASHEET FOR ALT MATLS) | 6 |

| 13 | 568-443 | 99609443 | O-RING, WEAR PLATE | 3 |

| 14 | 6490-25 | FLANGE, LINER RETAINER (LINER BUSHING) | 3 | |

| 15 | 6590-25 | NUT, LINER RETAINER | 3 | |

| 16 | 4690-25A | ASSY, VALVE COVER PLUG (INCLUDES ITEMS 15,16, 20-22) | 6 | |

| 17 | PLUG, VALVE COVER | 6 | ||

| 18 | 4488-25 | RING, THREADED (THREADED FLANGE) | 6 | |

| 19 | 4588-25 | CAP, THREADED (SCREW GLAND) | 6 | |

| 20 | P-115 | 7207115 | SEAL, VALVE COVER PLUG - RUBBER (SEE DATASHEET FOR ALTERNATE MATERIALS) | 6 |

| 21 | 4788R-25 | ASSEMBLY, VALVE GUIDE (INCLUDES ITEMS 20 & 21) | 6 | |

| 22 | 4700I | *20200004 | BUSHING, VALVE GUIDE (BUNA) | 6 |

| 23 | 4018-18 | 700030711 | SCREW, VALVE GUIDE | 12 |

| 24 | 4018-19 | 700048511 | CAPSCREW, SUCTION MANIFOLD | 24 |

| 25 | 568-442 | 99609442 | GASKET, SUCTION MANIFOLD | 3 |

| 26 | 8376-25MOD | MANIFOLD, DISCHARGE | 1 | |

| 27 | 2988 | 1290344 | SEAL, DISCHARGE MANIFOLD | 3 |

| 28 | 8590/6/1- | SUCTION MANIFOLD | 1 | |

| Item | Description | Part No. |

| Complete Assembly | 8488-1 | |

| 1 | Discharge Module | 8488-1 |

| 2 | Suction Module | 8488-2 |

| 3 | Screw Gland | 4575 |

| 4 | Threaded Flange | 4475 |

| 5 | Wear Plate | 8488-4 |

| 6 | Plug Assembly w/Guide & Bushing | 4675-1A |

| 7 | Liner Retainer Flange | 6488-1 |

| 8 | Liner Retainer Nut | 6588-1 |

| 9 | Module Gasket | 2988 |

| 10 | Valve Cover Plug Seal | P-129 |

| 11 | Valve Guide Bushing | 4700-I |

| 12 | Valve Guide | 4775 |

| 13 | Valve Cover Stud w/Nut | 4015-2 |

| 14 | Power End Stud w/Nut | 4016-96 |

| 15 | Liner Retainer Capscrew | 4017-4 |

| 16 | Suction Module Stud w/Nut | 4016-97 |

| 17 | Wear Plate Gasket | 2974-I |

| 18 | Liner Retainer Screw Set | 8488-7 |

| 19 | Dowel Pin | 8488-5 |

| 20 | Discharge Manifold Stud | 4016-3 |

| 21 | Valve Guide Screw | 4018-88 |

| 22 | Piston Rod | 1290-25 |

| 23 | Sub Rod | 1290-1 |

| 24 | Piston Rod Connecting Stud | 1290-2 |

| 25 | Rod Clamp w/Spray System | 1290-CW |

| Item | Description | Part No. |

| Complete Assembly | 8476-A | |

| 1 | Threaded Flange | 4476 |

| 2 | Screw Gland | 4597 |

| 3 | Plug Assembly w/Guide & Bushing | 4676-2A |

| 4 | Valve Guide | 4776 |

| 5 | Valve Guide Bushing | 4700-I |

| 6 | Valve Guide Screw | 4016-98 |

| 7 | Valve Cover Stud w/Nut | 4015-54 |

| 8 | Power End Stud w/Nut | 4015-95 |

| 9 | Liner Retainer Capscrew | 4017-65 |

| 10 | Liner Retainer Flange | 6476 |

| 11 | Liner Retainer Nut | 6576 |

| 12 | Suction Module Stud w/Nut | 4018-17 |

| 13 | Suction Module (Studded) | 8476-2 |

| 14 | Discharge Module (Studded) | 8476-1 |

| 15 | Dowel Pin | 8488-5 |

| 16 | Wear Plate | 8476-3 |

| 17 | Valve Cover Plug Seal | P-107 |

| 18 | Module & Wear Plate Seal | 2988 |

| 19 | Piston Rod | 1286-32 |

| 20 | Sub Rod | 1286-1 |

| 21 | Rod Clamp w/Spray System | 1286-CW |

| TSC PART # | DESCRIPTION |

| TS-0-6316-0357-00 | FLUID END MODULE STUDDED * (ITEMS 1, 2, 3, 4, 5, 6, 7,8) |

| TS-0-7507-2013-00 | STUD, MODULE TO LINER CLAMP |

| TS-0-7601-0610-18 | LINER CLAMP STUD NUT |

| TS-0-7507-2201-00 | POWER FRAME STUD |

| TS-0-7507-2210-00 | STUD, MODULE TO CYLINDER |

| TS-0-7601-0630-17 | NUT (FOR ABOVE) |

| TS-0-7507-2108-00 | STUD, MODULE TO DISC. MANIFOLD |

| TS-0-7601-0630-24 | NUT (FOR ABOVE) |

| TS-0-6316-0354-00 | GUIDE, LOWER VALVE (WITH BUSHING) |

| TS-0-6316-0096-00 | BUSHING, LOWER VALVE GUIDE |

| TS-0-6316-0360-00 | LOCKBOLT, LOWER VALVE GUIDE |

| TS-0-6316-0363-00 | ALIGNMENT RING |

| TS0-6316-0369-0099(G-801) | GASKET, HEAD SEAL |

| TS-0-6316-0364-00 | PLUG, CYLINDER HEAD |

| TS-0-6316-0361-00 | RING, THREADED CYLINDER HEAD |

| TS-0-6316-0362-00 | CAP, THREADED CYLINDER HEAD |

| TS-0-6316-0092-00(G-741) | GASKET, VALVE COVER |

| TS-0-7501-0051-00 | SCREW, RETAINER UPPER) |

| TS-0-6397-0603-00 | PLATE, RETAINER (UPPER) |

| TS-0-6397-0575-00 | GUIDE, UPPER VALVE |

| TS-0-6316-0039-00 | COVER, VALVE POT |

| TS-0-6316-0373-00 | GASKET, WEAR PLATE |

| TS-0-6316-0365-00 | PLATE, WEAR |

| TS-0-6316-0373-00(G-800) | GASKET, LINER |

| TS-0-6316-0366-00 | RING, LINER THREADED |

| TS-0-6316-0367-00 | LINER LOCK |

| TS-0-7602-1600-25 | GASKET, DISCHARGE MANIFOLD |

| TS-0-7602-1600-61 | GASKET, SUCTION MANIFOLD |