|

|

[China]

Trade Verify

Address: Suite 1004, Hongan Plaza, #258 Die Yuan Road, Yinzhou District, Ningbo City, China

Contact name:Richard SHEN

TORICH INTERNATIONAL LIMITED |

|

Verified Suppliers

|

|

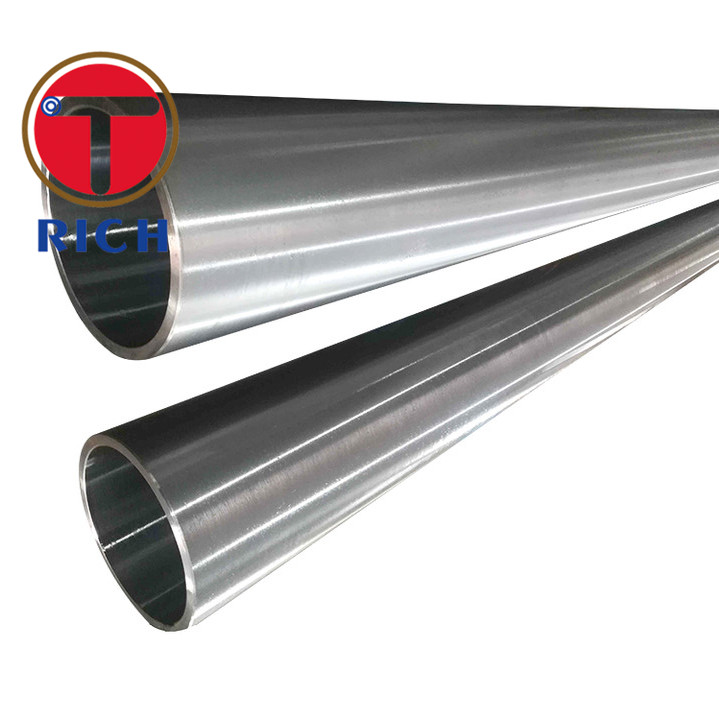

316 Stainless Steel Quilted Grinding Pipe Hydraulic Cylinder Tube

Stainless steel quilted pipe can be directly used for hydraulic cylinder liner, cylinder block,

cylinder pull rod and other hydraulic cylinder products without processing.

High quilting accuracy,

inner hole precision H7-H10,

inner hole roughness less than 0.63nm,

standard straightness less than 0.3mm/m.

High precision stainless steel quilted pipe is used in hydraulic, cylinder, pipeline, textile, printing,

shock absorption, precision bushing and other high precision machinery fields.

Stainless steel tube surface grinding girders and piston seal is

the main factor causing the hydraulic

oil cylinder have diarrhoea, if the grinding tube produce longitudinal girders, mark,

even if the update of the piston seal, also cannot effectively troubleshoot,

quilted surface grinding tube line mainly check the dimensional tolerance,

position tolerances whether meet the technical requirements, with or without longitudinal tensile mark,

and mark depth measurement, adopt corresponding solutions.

1. There are trace changes and shallow tensile marks in the

stainless steel quilted pipe,

which can be repaired by honing process or coating.

2. If the surface of stainless steel quilting pipe is seriously

worn and there are deep longitudinal tensile marks,

it should be mapped according to the real objects and reproduced and replaced by a professional

manufacturer's quilting pipe manufacturing process. Recent data show that TS311 can be used to reduce wear and

repair the large-diameter quilting pipe. Anti-wear repair agent is mainly used for repairing worn and scratched metal parts.

Quilted pipe repair grinding process, alloy blade on the surface scratch out a depth of 1 mm above the groove,

and then use clean grooved surface, with grinding tuned pipe inner contour plate girders TS311 antifriction repairing

adhesive coat in good polished surface, forcibly leveling, ensure the compaction, and higher than that of quilted grinding

tube surface, after being solidified, polished and set aside the finishing allowance.