TORICH INTERNATIONAL LIMITED |

|

Verified Suppliers

|

|

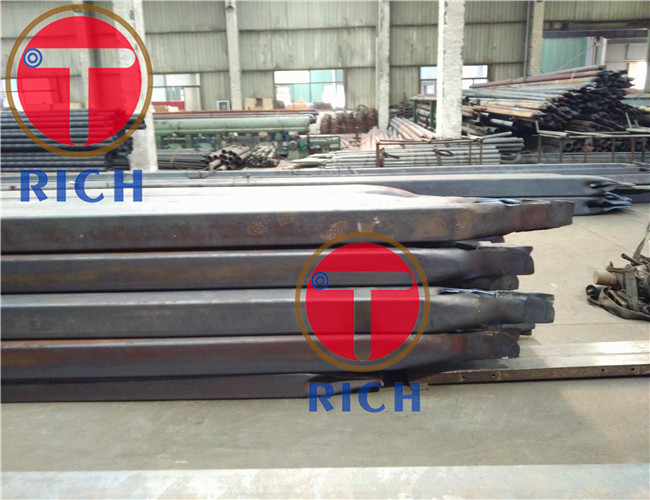

ASTM A500 GrB Cold Formed Structural Carbon Steel Square Tube

Standard: ASTM A500 Seamless Steel Rectangle Tubing

Cold-Formed Seamless Carbon Structural Tubing in Rounds and

Shapes Rectagnle and Square

Applications:

For construction of bridges, and buildings, and for general strcutrual purposes,

For Algricultrual Michinery, Engineering etc.

Size range:

Square tubes O.D. :20-20 to 500-500mm W.T.:1-24mm L:max12000mm

Rectangle tubes O.D. :20-30 to 400-600mm W.T.:1-24mm L:max12000mm

Steel Grade:

ASTM A500 -- GrB GrC

S355JR Q235 Q345

Manufacture:

Tubes are made by seamless process.

The tubing may be stress relieved or annealed, as is considered necessary by the tubing manufacturer, to conform to the requirements of this specification.

Tolerance:

Straightness--The permissible variation for straightness of structural tubing shall be 1/8 in times the number of feet (10.4mm times the number of meters) of total length divided by5.

Squareness of sides— For square and rectangular structural tubing, adjacent sides may deviate from 90° by a tolerance of ±2° maximum.

Radius of Corners— For square or rectangular structural tubing, the radius of any outside corner of the section shall not exceed three times the specified wall thickness.

Workmanship, Finish, and Appeaerance:

All tubing shall be free from defects and shall have a workmanlike finish.

Surface imperfections shall be classed as defects when their depth the remaining wall thickness to less than90% of the specified nominal wall thickness.

Quality Control

1~ Incoming Raw Material Inspection

2~ Raw Material Segregation to avoid steel grade mix-up

3~ Heating and Hammering End for Cold Drawing

4~ Cold Drawing and Cold Rolling, on line inspection

5~ Heat Treatment, +A, +SRA, +LC, +N, Q+T

6~ Straightening-Cutting to specified length-Finished Measuring

Inspection

7~ Machanical Testing in own labs with Tensile Strength, Yield

Strength, Elongation, Hardness, Impact, Mictrostruture etc

8~ Packing and Stocking.