TORICH INTERNATIONAL LIMITED |

|

Verified Suppliers

|

|

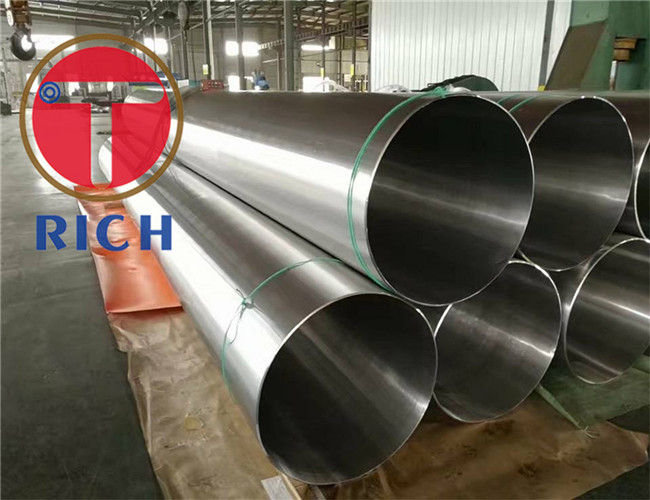

Product Name: GB/T24593 12Cr18Ni9 06Cr18Ni11Ti 304/316Welded austenitic boiler and heat-exchanger Stainless Steel Pipes

Size range: O.D.:3-500mm W.T.:0.5-50mm L:2000-12000mm according to customers' actual application and production.

Application : For boiler and heat-exchanger

Steel Grade: 12Cr18Ni9,06Cr19Ni10,022Cr19Ni10,06Cr25Ni20,022Cr22Ni5Mo3N,019Cr19Mo2NbTi,06Cr13Al

Characteristic:

Good concentricity

Good surface quality

Good OD and ID tolerance

High Precision

Stable quality

Smooth Roughness

TORICH QUALITY ASSURANCE

Table1Tolerance of OD

| Classification | Nominal OD | Permissible Tolerance | ||

| PC | PB | PA | ||

H T | <25 | ±0.20 | ±0.15 | ±0.10 |

| ≥25~<40 | ±0.30 | ±0.25 | ±0.20 | |

| ≥40~<63 | ±0.50 | ±0.30 | ±0.25 | |

| ≥63~<90 | ±0.60 | ±0.50 | ±0.40 | |

| ≥90~<159 | ±0.80 | ±0.65 | ±0.50 | |

| ≥159~<300 | ±0.8%D | ±0.7%D | ±0.5%D | |

| ≥300~<610 | ±0.1%D | ±0.8%D | ±0.6%D | |

| ≥10 | protocol | protocol | protocol | |

WC SP | <25 | ±0.15 | ±0.12 | ±0.10 |

| ≥25~<40 | ±0.20 | ±0.15 | ±0.13 | |

| ≥40~<50 | ±0.20 | ±0.18 | ±0.15 | |

| ≥50~<60 | ±0.25 | ±0.20 | ±0.18 | |

| ≥60~<90 | ±0.30 | ±0.28 | ±0.25 | |

| ≥90~<100 | ±0.40 | ±0.35 | ±0.30 | |

| ≥100~<200 | ±0.5%D | ±0.4%D | protocol | |

| ≥200 | protocol | protocol | protocol | |

Table 2Tolerance of WT

| Nominal WT | Permissible Tolerance |

| <0.5 | ±0..10 |

| ≥0.5~1.0 | ±0.15 |

| >1.0~2.0 | ±0.20 |

| >2.0~<4.0 | ±0.30 |

| ≥4.0 | ±10%S |

Table 3 Bending Degree

| Nominal Wall Thickness/mm | Bending Degree/(mm/m) |

| ≤108 | ≤1.0 |

| >108~325 | ≤1.5 |

| >325 | ≤2.5 |

Table 3 chemical composition

| Steel grade | Chemical compositon % | ||||||||

| C | Si | Mn | P | S | Ni | Cr | Mo | N | |

| 12Cr18Ni9 | 0.15 | 1.00 | 2.00 | 0.035 | 0.03 | 8.00~10.00 | 17.00 ~19.00 | — | 0.10 |

| 06Cr18Ni10 | 0.08 | 1.00 | 2.00 | 0.035 | 0.03 | 8.00~11.00 | 18.00 ~20.00 | — | — |

| 022Cr19Ni10 | 0.030 | 1.00 | 2.00 | 0.035 | 0.03 | 8.00~12.00 | 18.00 ~20.00 | — | — |

| 07Cr19Ni10 | 0.04~0.10 | 1.00 | 2.00 | 0.035 | 0.03 | 8.00~11.00 | 18.00 ~20.00 | — | — |

| 06Cr19Ni10N | 0.08 | 1.00 | 2.00 | 0.035 | 0.03 | 8.00~11.00 | 18.00 ~20.00 | — | 0.10 ~0.16 |

| 022Cr19Ni10N | 0.030 | 1.00 | 2.00 | 0.035 | 0.03 | 8.00~11.00 | 18.00 ~20.00 | — | 0.10 ~0.16 |

| 10Cr18Ni12 | 0.12 | 1.00 | 2.00 | 0.035 | 0.03 | 10.50~13.00 | 18.00 ~20.00 | — | — |

| 06Cr23Ni13 | 0.08 | 1.00 | 2.00 | 0.035 | 0.03 | 12.00~15.00 | 17.00 ~19.00 | — | — |

| 03Cr25Ni20 | 0.08 | 1.00 | 2.00 | 0.035 | 0.03 | 19.00~22.00 | 22.00 ~24.00 | — | — |

| 06Cr17Ni12Mo2 | 0.08 | 1.00 | 2.00 | 0.035 | 0.03 | 10.00~14.00 | 24.00 ~26.00 | 2.00 ~3.00 | — |

| 022Cr17Ni12Mo2 | 0.030 | 1.00 | 2.00 | 0.035 | 0.03 | 10.00~14.00 | 16.00 ~18.00 | 2.00 ~3.00 | — |

| 06Cr17Ni12Mo2Ti | 0.08 | 1.00 | 2.00 | 0.035 | 0.03 | 10.00~14.00 | 16.00 18.00 | 2.00 ~3.00 | — |

| 06Cr17Ni12MoN | 0.08 | 1.00 | 2.00 | 0.035 | 0.03 | 10.00~13.00 | 16.00 ~18.00 | 2.00 ~3.00 | 0.10 ~0.16 |

| 022Cr17Ni12Mo2N | 0.030 | 1.00 | 2.00 | 0.035 | 0.03 | 10.00~13.00 | 16.00 ~18.00 | 2.00 ~3.00 | 0.10 ~0.16 |

| 06Cr19Ni13Mo3 | 0.08 | 1.00 | 2.00 | 0.035 | 0.03 | 11.00~15.00 | 16.00 ~18.00 | 3.00 ~4.00 | — |

Table 4 Mechanical Property

| No. | No.in GB/T20878 | Unified digital code | STEEL GRADE | Recommended heat treatment system | Tensile property | Hardness | |||

tensile strength Rm/(N/MM2) | Stipulated elongation strength of plastic mold Rp0.2/(N/mm2) | Elongation A/% | HRB | ||||||

| ≥ | ≤ | ||||||||

| 1 | 13 | S30210 | 12Cr18Ni9 | ≥1040℃.Rapid cooling | 515 | 205 | 35 | 90 | |

| 2 | 17 | S30408 | 06Cr19Ni10 | ≥1040℃.Rapid cooling | 515 | 205 | 35 | 90 | |

| 3 | 18 | S30409 | 022Cr19Ni10 | ≥1040℃.Rapid cooling | 485 | 170 | 35 | 90 | |

| 4 | 19 | S30458 | 07Cr19Ni10 | ≥1040℃.Rapid cooling | 515 | 205 | 35 | 90 | |

| 5 | 23 | S30458 | 06Cr19Ni10N | ≥1040℃.Rapid cooling | 550 | 240 | 35 | 90 | |

| 6 | 25 | S30453 | 022Cr19Ni10N | ≥1040℃.Rapid cooling | 515 | 205 | 35 | 90 | |

| 7 | 26 | S30510 | 10Cr18Ni12 | ≥1040℃.Rapid cooling | 515 | 205 | 35 | 90 | |

| 8 | 32 | S30908 | 06Cr23Ni13 | ≥1040℃.Rapid cooling | 515 | 205 | 35 | 90 | |

| 9 | 35 | S31008 | 06Cr23Ni20 | ≥1040℃.Rapid cooling | 515 | 205 | 35 | 90 | |

| 10 | 38 | S31608 | 06Cr17Ni12Mo2 | ≥1040℃.Rapid cooling | 515 | 205 | 35 | 90 | |

| 11 | 39 | S31603 | 022Cr17Ni12Mo2 | ≥1040℃.Rapid cooling | 485 | 170 | 35 | 90 | |

| 12 | 41 | S31668 | 06Cr17Ni12Mo2Ti | ≥1040℃.Rapid cooling | 515 | 205 | 35 | 90 | |

| 13 | 43 | S31658 | 06Cr17Ni12Mo2N | ≥1040℃.Rapid cooling | 550 | 240 | 35 | 90 | |

| 14 | 44 | S31653 | 022Cr17Ni12Mo2N | ≥1040℃.Rapid cooling | 515 | 205 | 35 | 90 | |

| 15 | 49 | S31708 | 06Cr19Ni13Mo3 | ≥1040℃.Rapid cooling | 515 | 205 | 35 | 90 | |

| 16 | 50 | S31703 | 022Cr19Ni13Mo3 | ≥1040℃.Rapid cooling | 515 | 205 | 35 | 90 | |

| 17 | 55 | S32168 | 06Cr18Ni11Ti | ≥1040℃.Rapid cooling | 515 | 205 | 35 | 90 | |

| 18 | 62 | S34778 | 06Cr18Ni11Nb | ≥1040℃.Rapid cooling | 515 | 205 | 35 | 90 | |

| 19 | 63 | S34779 | 07Cr18Ni11Nb | ≥1040℃.Rapid cooling | 515 | 205 | 35 | 90 | |

Table 5 Inspection items and sampling quantity

| Inspection items | sampling quantity |

| Chemical composition | Each furnace Take one sample |

| Tensile test | One sample for each batch on two test tubes |

| Hardness test | One sample for each batch on two test tubes |

| Flattening test | One sample for each batch on two test tubes |

| Coiling test | One sample for each batch on two test tubes |

| Expansion test | One sample for each batch on two test tubes |

| Reversed bending test | One sample at every 450M of tubes |

| longitudinal flattenin test | One sample for each batch on two test tubes |

| Hydraulic test | Per piece |

| Eddy current flaw detection | Per piece |

| Intergranular corrosion test | One sample for each batch on two test tubes |

| Grain size test | One sample for each batch on two test tubes |

| Ray detection | Per piece |

| Underwater air tightness test | Per piece |