TORICH INTERNATIONAL LIMITED |

|

Verified Suppliers

|

|

EN 10208 Standard Steel Pipe for pipelines for combustible fluids

The process by which a flat product is formed into a pipe without heating of the plate or strip.Cold working operation with a permanent strain greater than the maximum strain of 1.5% which differentiates it from sizing operations specified in table. For seamless pipe, the entire pipe; for welded pipes, the entire pipe excluding weld(S) and heat affected zone (HAZ)

Normalizing forming

Forming process in which the final deformation is carried out in a

certain temperature range leading to a material condition

equivalent to that obtained after normalizing so that the specified

values of the mechanical properties are retained even after

normalizing.

Quenching and tempering

Heat treatment comprising of quench hardening followed by

tempering, where quench hardening implies austenitiization followed

by cooling, under conditions such that austenite transforms more or

less completely into martensite and possibly into bainite.

NOTE1 By tempering to specific temperature (<AC1) one or more times

or holding at these temperatures, followed by cooling at an

appropriate rate, the properties are brought to the required level.

NOTE2 The abbreviated form of this delivery condition is Q

Imperfection

Irregularity in the wall or on the pipe surfaces detectable by

methods described in this document

Note Imperfections with a size and/or population density complying

with the acceptance criteria specified in this document.

Note Defects are considered to adversely affect or limit the

intended use of the product.

ERW piping and manufacturing route (starting material , pipe forming and heat treatment conditions)

| Normalizimg rolled strip | Cold forming | srtess relieved (welded area) Normalized (welded area |

| Cold forming and cold finishing | Normalized (entire pipe) Heat treated (weld area) | |

| The momechanically rolled strip Cold forming | Cold forming | Heat treated (weld area) |

Chemical composition of the cast analysis

L210GA 1.0319 C 0.21 Si 0.40 Mn0.90 P0.030 S0.030

L235GA 1.0458 C 0.16 Si 0.40 Mn1.20 P0.030 S0.030

L245GA 1.0459 C 0.20 Si 0.40 Mn1.15 P0.030 S0.030

L290GA 1.0483 C 0.20 Si 0.40 Mn1.40 P0.030 S0.030

L360GA 1.0499 C 0.20 Si 0.55 Mn1.45 P0.030 S0.030

Permissible deviations of the product analysis from the specified limits on cast analysis

Element Limiting value for the cast analysis according to Table 2

Permissible deviation of the product analysis

C ≤0.22

+0.02

Si ≤0.55

+0.05

Mn ≤1.45

+0.10

P ≤0.030

+0.005

S ≤0.030

+0.005

Al ≥0.015 <0.060

±0.005

V+Nb+Ti ≤0.15

+0.02

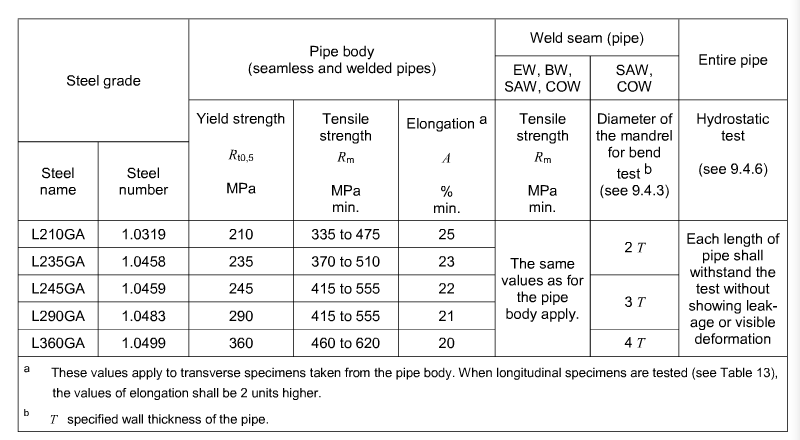

Requirements for the result of tensile and bend test and for the hydrostatic test

Torich Interational Co.,Ltd is a professional manufacturer and

exporter of steel pipes materials.

It is an international marketing and sales company specialized in

steel tubes, which holds the factories of Seamless Steel Tubes with

Carbon and Alloy Steel Grade, Welded Precision Steel Tubes,DOM

Steel Tubes, Seamless & Welded Stainless Steel Tubes with

Nickel and Alloy Steel Grade.

Our factory was established since 1997, with the name of Haiyan

Sanxin Steel Pipe Co., Ltd. The factories` technicians are of great

engineering experience in steel pipe industry for more than 20

years, which are in great command of production technology for Cold

Drawing and Cold Rolling. So we have strong technician team and

manufacturing capability.

Packing

Producing Process