Toxmann High- Tech Co., Limited |

|

Verified Suppliers

|

|

P20 Material CNC Lathe Machining Parts CNC Machinery Parts For Automation Industy

Processing & Inspection Machine List.pdf

Four standard threads of metric, inch, modulus and diameter control can be turned on a CNC lathe. No matter which thread is turned, a strict motion relationship must be maintained between the lathe spindle and the tool: that is, one revolution of the spindle (that is, the workpiece one turn), the tool should move evenly the distance of one lead (of the workpiece).

For general standard threads, thread ring gauges or plug gauges are used to measure. When measuring the external thread, if the "over-end" ring gauge of the thread is just screwed in, but the "end-stop" ring gauge cannot be screwed in, it means that the processed thread meets the requirements, otherwise it is unqualified. When measuring internal threads, use a thread plug gauge and measure in the same way. In addition to thread ring gauge or plug gauge measurement, other measuring tools can also be used to measure, measure the pitch diameter of the thread with a thread micrometer, use a tooth thickness vernier caliper to measure the pitch diameter of the trapezoidal thread and the pitch diameter of the worm. The measuring method measures the pitch diameter of the thread.

Manufacturer | Toxmann High- Tech Co., Limited |

Product Name | Precision Turned Parts |

Industry Standards | DIN, JIS, AISI, GB |

Design Tools | UG, ProE, Auto CAD, Solidworks, etc |

Surface Finishing | Nickel Plated |

Quality Inspection Instrument | Micrometer Calipers, Concentricity Measuring Instrument, Thread Gage |

Processing Machines | NC Lathe Machine |

Other Service | ODM and OEM, Customized Specification, One to One Communication |

Order Process | Customer inquiries (provide 2D or 3D drawing) →Toxmann provides quotes and lead time→ Orders released by customer→ 50% advanced payment→ Arrange production →QC pass→Packing and shipping after receiving balance payment. |

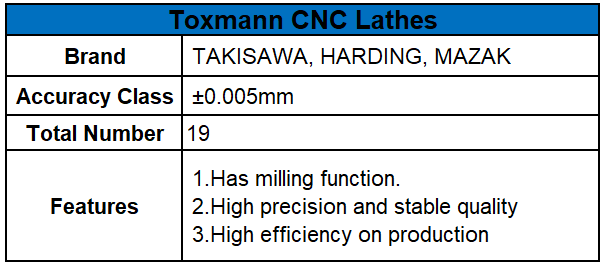

Toxmann has a group of high-precision NC Lathes and turning-milling compound machines imported from Japan and Taiwan. Our NC Lathes have been highly appreciated by our customers for their stable quality and efficient productivity. Here is our CNC Lathes list:

1. Automation industry

2. Communications industry

3. Military industry

4. Consumption industry

1. We have rich experience and specialize in manufacturing mold parts and machined parts for over 13 years.

2. We have perfect technical team and precision machines, which ensure to provide best service and quality to customers.

3. Short lead time of samples to impove work efficiency.

4. Professional production team and strictly quality management to meet the requirement of capacity and quality.

5. Competitive quotation, excellent service, flexible trade terms.

6. Our philosophy: customers' satisfaction is our target.

Toxmann High- Tech Co., Limited is a professional OEM/ODM mold accessories and machine parts manufacturer. We provide precision machined parts design and manufacture, mold design and mold manufacturing, injection/die-casting/stamping mold parts processing. We have a team with extensive quality control experience to help Toxmann meet customer requirements. High quality, competitive price, quick response are our core missions.

1. Provide the detailed production schedule for each order.

2. Offering production status with video and photos for each component.

3. Manufacture the parts base on customers' drawings to meet the quality requirements and industry standard.

4. Over 99% orders can meet the lead time requirement.

5. Respond to the enquiry within 24 hours and offer the quotation within 48 hours.

6. Using the first-rank raw materials which also can be traced.

7. Provide the most competitive price with the high quality and service standard.

8. The most reasonable packing scheme for all products.

FAQ:

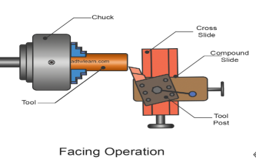

A: What is Turning? Turning is a machining process used to make cylindrical parts, where the cutting tool moves in a linear fashion while the workpiece rotates. Commonly performed with a lathe, turning reduces the diameter of a workpiece, typically to a specified dimension, and produces a smooth part finish.

Q2: What is step turning process?

A: Step turning is a turning process in which series of steps having different diameters is produced with the lathe machine. Procedure. Fix the cylindrical workpiece into the chuck and secure it properly.

Q3: What are the advantages of turning?

A: Advantages of the turning process:

All materials are compatible.

Very good tolerance.

Short lead time.

No high skilled operator required.

The material removal rate is flexible.

Q4: What are the three main movements of turning operations?

A: Therefore, there are three basic movements: Rotation movement: The part to be mechanized is placed on a rotating shaft, making it rotates around itself. Advanced movement: The tool moves parallel to the piece, making a straight movement that defines the machining contour.