Dongguan Yexin Intelligent Technology Co., Ltd. |

|

Verified Suppliers

|

|

The optimal application of CNC machining is found in one-off manufacturing tasks and in

low-to-medium volume production scenarios, typically ranging from several hundred to 1000 parts.

For cost-effectiveness, particularly in the production of metal prototypes, CNC machining is highly

recommended.

Additionally, when parts demand stringent tolerances, choosing CNC machining becomes imperative

for achieving precision.

Product Details

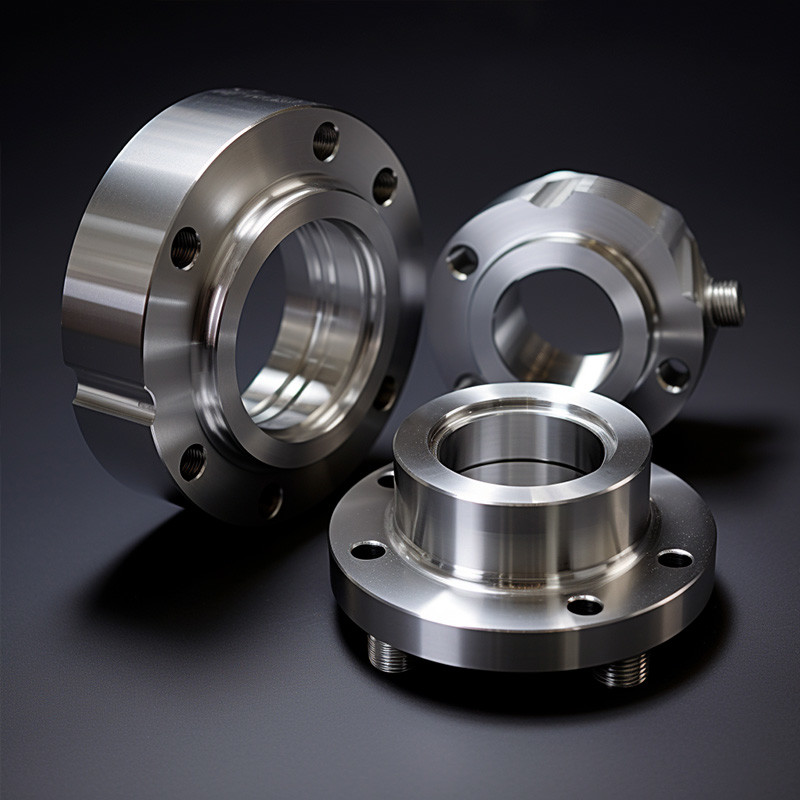

CNC machining machines exhibit the capability to cut a diverse range of materials, including

aluminum, bronze, copper, ceramics, plywood, various steel alloys, stone, wood, zinc,

and other engineering materials. This versatility makes CNC machining an ideal choice for

generating prototypes in product development. It enables precise and rapid adjustments until

achieving the desired end product.

The most common materials are:

| Common Metal Materials for CNC Machining | |

| Metal Material | Properties |

| Aluminum | 2024: Good fatigue resistance and strength; excellent toughness at moderate to high strength levels; improved fracture toughness |

| 6061: Excellent machinability, low cost, and versatility | |

| 7075: High strength, hardness, low weight, and heat tolerance | |

| Stainless steel | Excellent machinability and outstanding uniformity; good workability and weldability, high ductility and formability |

| Steel Alloy | Mix of chromium, molybdenum, and manganese yields toughness, good torsional and fatigue strength |

| Brass | Versatile and highly attractive copper/zinc alloy with warm yellow color accommodates severe forming/drawing |

| Copper | High ductility and high electrical and thermal conductivity; develops attractive blue-green surface patina over time |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive, and medical industries |

| Steel Mild Low Carbon | High machinability and weldability, high stiffness; good mechanical properties, machinability, and weldability at low cost |

| Surface Finishes | ||

| Name | Applicable to | Machining marks |

| As machined | Metals, Plastics | Visible, light surface scratches |

| Smooth machining | ||

| Fine machining | Metals | Slightly visible |

| Polishing | Metals | Removed on primary surfaces |

| Bead blasting | Metals | Removed for non-cosmetic, removed on primary surfaces for cosmetic |

| Brushing | Metals | |

| Anodizing Type II | Aluminum | |

| Anodizing Type III | Aluminum | Visible under anodizing |

| Black oxide | Copper, Stainless steel, Alloy steel, Tool steel, Mild steel | Visible |

| Powder coating | Metals | Removed |

| Brushed + electropolishing | Stainless steel | Removed on Primary surfaces |

CNC Machining Applications

Turning, a precision manufacturing technique, is adept at producing rotational, axi-symmetric parts

featuring intricate details such as holes, grooves, threads, tapers, and contoured surfaces.

Its proficiency shines in crafting limited-quantity items, particularly custom-designed shafts and

fasteners utilized in prototypes. Furthermore, turning serves as a valuable complementary process,

enabling the addition or refinement of features to parts manufactured through alternative methods.

Notable examples of products shaped through turning include camshafts, crankshafts, baseball bats,

bowls, cue sticks, signboards, musical instruments, and the legs of tables and chairs.

Company Profile

FAQ's

1. What are the advantages of CNC machining?

CNC machining offers a spectrum of advantages, prominently featuring rapid prototyping and the

expedited production of full-scale parts. Its hallmark is the ability to achieve exceptional precision

and accuracy in manufacturing, catering to tight tolerances for CNC parts of diverse sizes.

This method stands out for its flexibility, influencing factors such as volume, pricing, lead times,

and the array of materials and finishes available.

2. How much do CNC machining materials cost?

The diverse range of materials available for CNC machining introduces variability in costs,

influenced by both the specific material properties and overall characteristics.

When opting for metal parts, Aluminum 6061 emerges as a cost-effective choice.

For budget-conscious projects, ABS stands out as the most economical option.

It's essential to note that machining difficulty plays a crucial role in cost determination.

Materials like stainless steel, being harder than aluminum, pose greater machining challenges,

leading to an escalation in overall costs.

3. What are standard machining tolerances?

Standard machining tolerances are set at ± 0.005" or 0.13mm, delineating the acceptable range

for dimensions. For example, if a CNC machining tool carries a tolerance of ± 0.01 mm, it signifies

a permissible deviation of 0.01 mm in each cutting operation.

Leveraging a provided drawing, our CNC machining service can attain part tolerances as precise as

± 0.0002 in. In cases where no drawing is available, all CNC parts adhere to our ISO 2768 medium

standard.

Projects requiring even tighter tolerances, such as ±0.025mm or ±0.001", can be accommodated

with an engineering drawing specifying critical features.

4. What size of fillets are added when no specific fillet is specified by the 3D model

or drawing?

When no specific fillet radius is outlined in the 3D model or drawing, the machinist will incorporate

fillet radii at their discretion to optimize for easy machining.

In instances where a particular fillet radius is needed, explicit specification is encouraged.

As a rule of thumb, consider internal vertical edge radii exceeding 1/3 of the depth, while internal

horizontal edges may either remain sharp or be introduced with a radius ranging from 0.5mm to 1mm.