Dongguan Yexin Intelligent Technology Co., Ltd. |

|

Verified Suppliers

|

|

While traditional machining involves a skilled machinist manually operating a machine to remove

or shape metal based on specifications from designers and engineers, CNC machining performs

the same metal cutting, drilling, milling, boring, grinding, and other metal forming and removal

functions with a crucial distinction — it employs computer numerical control rather than manual

operation.

Traditional machining relies on tools such as turn wheels, dials, switches, chucks, vices, and

cutting tools made of materials like hardened steel, carbide, and industrial diamond.

Measurements are taken to ensure accuracy. In contrast, CNC machining is automated and

code-driven, developed by programmers.

It delivers consistent precision from the initial cut to subsequent repetitions, making it suitable for

digital manufacturing and low-volume production. CNC machining's advantage lies in its flexibility

for revisions and alterations, accommodating modifications and different materials with ease.

While traditional machining retains its place, CNC machining has largely taken over in

manufacturing, fabrication, and industrial production due to its superior precision and automation.

Product Details

The primary materials employed in the CNC machining process are predominantly metals.

These metals encompass alloy steel, carbon steel, cast iron, stainless steel, aluminum, copper,

magnesium, and zinc.

However, CNC machining is not limited to metals alone; it is also capable of machining plastic

parts and working with various materials, including ceramics, composites, thermoplastics, and

thermosets.

Here is a comprehensive overview of the most popular materials

| The Most Popular Materials | |

| Material | Characteristics |

| Aluminum 6061 | Good strength-to-weight ratio, excellent machinability, low hardness |

| Stainless Steel 304 | Excellent mechanical properties, resistant to corrosion & acid, relatively difficult to machine |

| Brass C360 | High ductility, excellent machinability, good corrosion resistance |

| Copper | Excellent thermal and electrical conductivity |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive and medical industries. |

| ABS | Excellent impact resistance, good mechanical properties, susceptible to solvents |

Nylon (PA6 & PA66) | Excellent mechanical properties, high toughness, poor moisture resistance |

| POM (Delrin) | High stiffness, excellent thermal & electrical properties, relatively brittle |

Surface Finishing

We specialize in the production of custom-made products and offer surface treatment services

tailored to meet our customers' specific requirements and industry standards.

Our comprehensive solutions are both efficient and cost-effective, making us a one-stop destination

with the capacity and capability to provide integrated services.

| Surface Finishing Options for CNC Machining | ||

| Name | Applicable Materials | Can be Applied with |

| Alodine | Aluminum | Media Blasting, Tumbling, Type II Anodizing* Type III Anodizing*, Type III Anodizing with PTFE* |

| Anodizing | Aluminum | Media Blasting, Tumbling, Alodine* |

| Black Oxide | Steel, Stainless Steel | Media Blasting, Tumbling, Passivation |

| Electroless Nickel Plating | Aluminum, Steel, Stainless Steel | Media Blasting, Tumbling |

| Electropolishing | Steel, Stainless Steel | — |

| Hand Polishing | Acrylic | Enhanced cosmetic appearance |

| Media Blasting | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | All post processes except Electropolish and Powdercoat |

| Nickel Plating | Aluminum, Steel, Stainless Steel | Media Blasting, Tumbling |

| Passivation | Steel, Stainless Steel | Black Oxide, Electroless Nickel Plating, Zinc Plating, Tumbling, Media Blasting |

| Powder Coating | Aluminum, Steel, Stainless Steel | — |

| Tumbling | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | All post processes except Electropolish and Powdercoat |

| Vapor Polishing | CNC Polycarbonate (Clear, Black) | Enhanced cosmetic appearance, near optically clear applications |

| Zinc Plating | Steel, Stainless Steel | Media Blasting, Tumbling, Passivation |

Specialist Industries

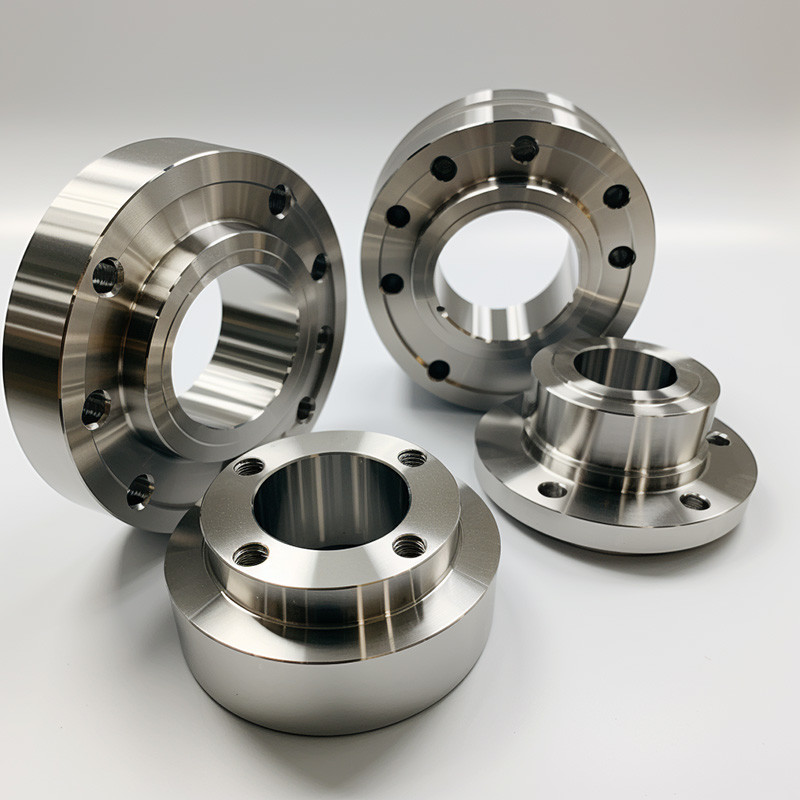

CNC turning machines excel in precision craftsmanship, fabricating a wide spectrum of parts with

diverse complexities. Among these are shafts and axles, pivotal components in industries such as

automotive and aerospace.

The precision extends to the production of bushings and bearings, crucial for reducing friction and

ensuring smooth rotational movement in mechanical assemblies. CNC turning further facilitates the

creation of connectors, fittings, and fasteners like screws and nuts, serving applications in plumbing,

hydraulic systems, and across various industries.

The technology is also applied in the manufacturing of valves and valve components, contributing

to fluid control systems. Additionally, CNC turning is instrumental in crafting tooling components,

including inserts, toolholders, and bodies, enhancing efficiency and accuracy in machining operations.

In the automotive sector, CNC turning is harnessed for producing engine components, pulleys,

brackets, and specialized parts.

Company Profile

FAQ's

1. How much does CNC machining cost?

The cost of CNC machining is determined by factors such as complexity, quantity, and lead time.

To obtain a precise cost estimate, we encourage you to submit a 3D CAD model, enabling us to

provide an interactive quote accompanied by design for manufacturability (DFM) feedback.

Our use of proprietary software and automated fixturing processes eliminates upfront non-recurring

engineering (NRE) costs, making CNC machining a cost-effective choice for quantities as low as 1 to

200 parts. While prices may be comparable or slightly higher than 3D printing, CNC machining

delivers superior material properties and surface finishes.

2. What are the advantages of CNC machining?

The advantages of CNC machining are prominent, with rapid prototyping and efficient full-scale

production at the forefront. A distinguishing feature is its capacity for high precision and accuracy

in manufacturing, extending to tight tolerance machining for CNC parts spanning various sizes.

Beyond this, CNC machining offers unmatched flexibility in addressing volume needs, pricing

considerations, lead times, and the utilization of a broad spectrum of materials and finishes.

3. How quickly can I get my parts?

For quality parts, a turnaround time of as little as two weeks is possible when complete 2D and 3D

CAD models are provided. Parts with more complexity or special features may take longer.

To obtain precise lead times for your project, request a quote.

In terms of shipping, the majority of our shipments use air freight, ensuring delivery within a few

days from China to Europe or North America.