Dongguan Yexin Intelligent Technology Co., Ltd. |

|

Verified Suppliers

|

|

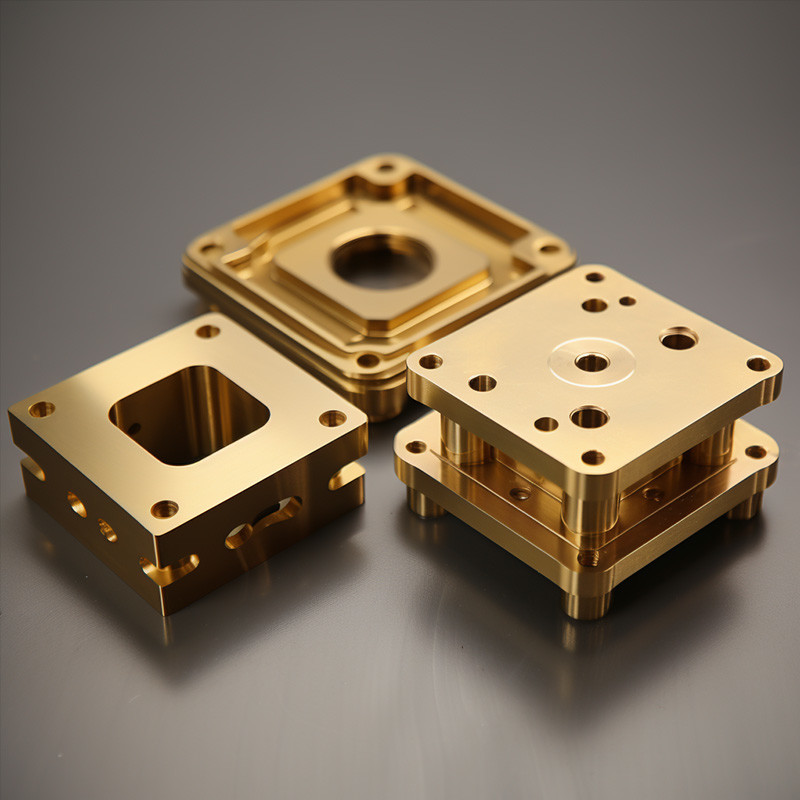

CNC machining employs subtractive processes, wherein the feedstock undergoes machining to

attain its final shape by systematically eliminating material. This involves tasks like drilling holes,

boring pathways, and shaping metal stock into new material with diverse tapers, diameters,

and shapes.

In contrast to additive manufacturing methods that involve adding, layering, and deforming

materials to achieve a specified shape, CNC machining achieves shapes by removing material in

subtractive manufacturing.

It also differs from injection molding, where material is injected into a mold in a different state of

matter to form a specified shape. The versatility of CNC machining spans various materials,

including metals, plastics, wood, glass, foam, and composite materials, making it a widely embraced

choice for efficient and precise fabrication in diverse industries.

Product Details

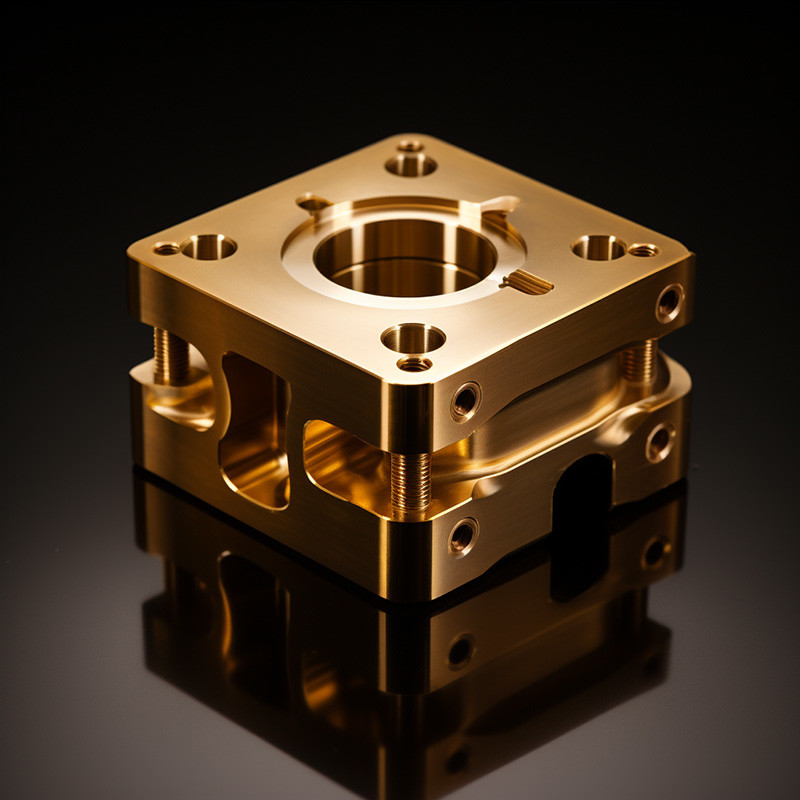

Brass, an alloy composed of copper and zinc, is a highly sought-after material for various

components.

Its exceptional dimensional accuracy, sturdiness, durability, and resistance to corrosion make

it a widely demanded choice for copper-based products.

| Common Brass Materials | |

| No. | Properties |

| Brass C3600 | It has superior machinability, thread rolling and knurling characteristics. Typically used in the manufacture of fluid connectors, threaded inserts, couplings, and more. |

| Brass C3602 | It’s strength and resistance to corrosion with properties closely resembling that of steel. It is ideal for some of the most demanding conditions such as heavy industrial parts. |

| Brass C3604 | It is used in the mass production of brass components. It is widely used in manufacturing hardware, connector, flange and other machine parts by lathe and CNC. |

| Brass C4926 | A low leaded free cutting brass which conform RoHs and Reach environment regulations. Widely used on electronic parts, precision machine, valves, and related parts. |

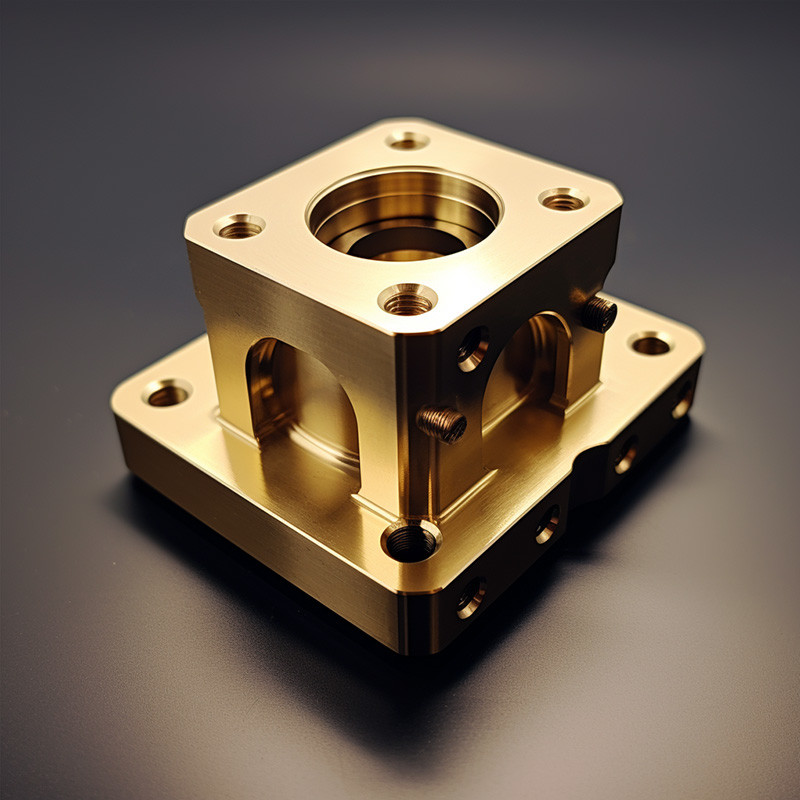

Brass Finishing and Post-Processing

360 Brass has a shiny yellow finish that varies depending on surface roughness.

It can be hand-polished to increase its sheen, or media blasted for more of a matte texture.

| Name | Machining Marks |

| As machined | Visible, light surface scratches |

| Smooth machining | Visible, light surface scratches |

| Fine machining | Slightly visible |

| Polishing | Removed on primary surfaces |

| Bead blasting | Removed for non-cosmetic, removed on primary surfaces for cosmetic |

| Brushing | Reduced for non-cosmetic, removed on primary surfaces for cosmetic |

| Powder coating | Removed |

| Black oxide | Visible |

Applications of CNC Brass Parts

CNC machining is widely used in various industries, including aerospace, automotive, consumer

electronics, robotics, agriculture, medical devices, household goods, energy, and oil and gas.

It is a common and essential manufacturing process globally.

Company Profile

FAQ's

1. How can I be assured that my design will be treated confidentially?

We take confidentiality seriously and are willing to sign and

uphold any non-disclosure or

confidentiality agreement. Additionally, our factory strictly prohibits the taking of photographs

of a customer's product without explicit permission.

Ultimately, our commitment to preserving your design's confidentiality is reinforced by our

longstanding reputation, having worked with hundreds of thousands of unique designs over many

years, without ever divulging proprietary information to third parties.

2. How does compare to other suppliers in terms of price?

While direct comparisons can be challenging, We generally offers

prices that are typically 25-45%

lower for plastic injection mold tools and CNC machined/turned parts when compared to suppliers in

North America and Europe.

In contrast to Chinese suppliers, our strategy is not to compete

solely on price. Instead, we prioritize

delivering the highest levels of quality, swift response times, and professional results.

3. What is the turnaround time for receiving my parts?

High-quality parts can be manufactured in as little as two weeks if

you furnish us with comprehensive

2D and 3D CAD models. However, more intricate parts with special features or requirements may

necessitate a longer production time. To obtain more precise lead times tailored to your project,

please request a quote.

Regarding shipping, the majority of our shipments are handled via air freight, taking a few days for

delivery from China to Europe or North America.