|

|

[China]

Trade Verify

Address: Hengjiao Industry Zone, Hengjiao Village, Shijie Town, Dongguan, Guangdong, China

Contact name:Hafrey

Dongguan Yexin Intelligent Technology Co., Ltd. |

|

Verified Suppliers

|

|

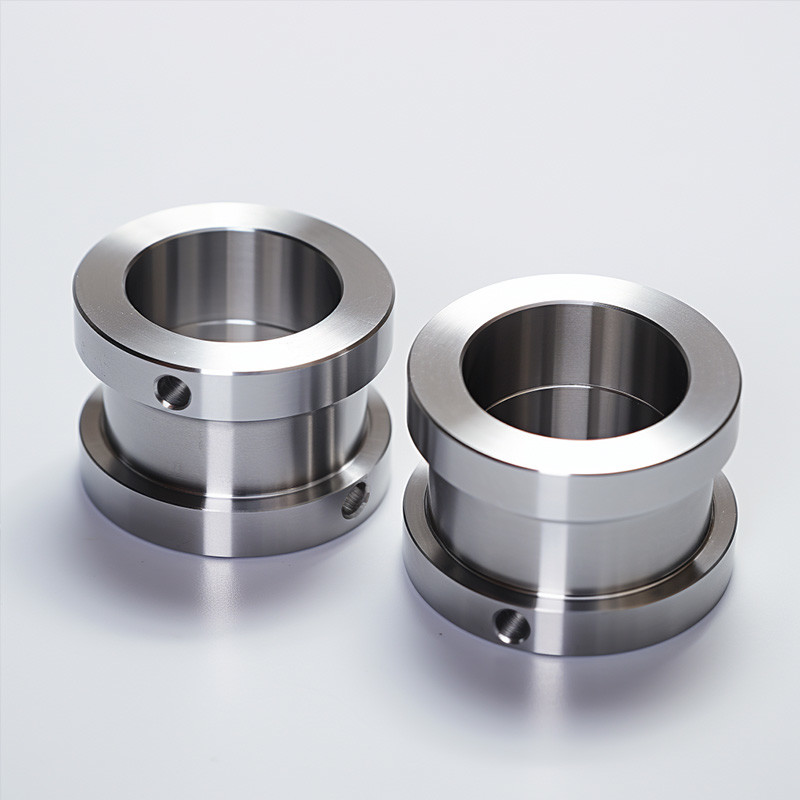

Our CNC turning process enables the rapid production of custom prototypes and end-use production

parts, often with turnaround times as short as 1 day.

Utilizing a CNC lathe equipped with live tooling capabilities, we can efficiently machine various

features, including axial and radial holes, flats, grooves, and slots.

CNC turning is commonly employed for the following applications:

Functional prototypes and end-use components.

Parts featuring cylindrical characteristics.

Components with axial and radial holes, flats, grooves, and slots.

Product Details

The primary materials employed in the CNC machining process are predominantly metals.

These metals encompass alloy steel, carbon steel, cast iron, stainless steel, aluminum, copper,

magnesium, and zinc.

However, CNC machining is not limited to metals alone; it is also capable of machining plastic

parts and working with various materials, including ceramics, composites, thermoplastics,

and thermosets.

| Common Materials | |

| Name | Description |

| Aluminum | High machinability and ductility, good strength-to-weight ratio. |

| Stainless steel | High tensile strength, corrosion and temperature resistant. |

| Mild steel | High machinability and weldability, high stiffness. |

| Brass | Low friction, excellent electrical conductivity, golden appearance. |

| Copper | Excellent thermal and electrical conductivity. |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive and medical industries. |

| POM | High stiffness, high accuracy, low friction, easy to machine. |

| ABS | Common thermoplastic, impact resistant, easy to machine. |

| Nylon | Excellent mechanical properties, thermal, chemical and abrasion resistant. |

| CNC Turning Tolerances | ||

| Limits for nominal size | Plastics | Metals |

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.10mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.20mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.30mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.50mm |

| Over 2000mm to 4000mm | ±2.0mm | |

| *Please clearly indicate tolerances for nominal sizes below 0.5mm on your technical drawing. | ||

Typical Applications of CNC Turning

CNC machining is a prevalent subtractive manufacturing process, and its utilization is extensive

across various industries. Some of the industries that heavily rely on CNC machining include:

1. Aerospace:

The aerospace industry extensively utilizes CNC machining for the

production of precise and

complex components used in aircraft and spacecraft.

2. Automotive:

In the automotive sector, CNC machining plays a crucial role in

manufacturing high-precision

components for vehicles, ensuring efficiency and reliability.

3. Aviation:

The aviation industry relies on CNC machining for the production of

components that require

exceptional precision and adherence to strict quality standards.

4. Transportation:

The transportation industry, encompassing various modes such as

trains and ships, utilizes CNC

machining for the fabrication of critical components for smooth and reliable operation.

Company Profile

FAQ's

1. How much do CNC machining materials cost?

The cost of CNC machining materials is influenced by the selected material, with each material

carrying its own price tag based on unique physical properties. The variety of materials available

for CNC machining contributes to the diverse cost landscape.

For metal parts production, Aluminum 6061 emerges as the most cost-effective option.

If cost efficiency is paramount, ABS is the most economical choice. The ease of machining plays

a significant role in cost dynamics, exemplified by stainless steel. Its greater hardness relative to

aluminum increases machining complexity, resulting in a higher overall cost.

2. Tolerance Specifications for Machined Parts

Our tolerances for machined parts are outlined below:

Local tolerances of +.005”/- .005” are applied across most geometries in metals, while plastics

have a tolerance variation of +/- 0.010". Tolerance specifications may vary for large parts,

especially concerning flatness after heat treatment.

For CNC parts with an "As Milled" finish, a minimum surface finish of 125 is required.

Fabricated parts adhere to a dimensional tolerance of 0.010” and an angular tolerance of 1°.

Tapped holes not explicitly identified as features on the quoted CAD model may be machined to

the diameters specified in that model.

Surface treatments (e.g., anodize, bead blast, iridite, powder coat, etc.) will not be applied unless

specifically paid for and acknowledged.

3. How long does delivery time and quotation take?

The delivery time for parts is determined by their complexity:

Low-complexity parts: 2-3 days

Moderate-complexity parts: 2-5 days

High-complexity parts: 5-15 days

Quoting time varies based on design complexity:

Simple designs: 1 business day or faster

Moderate to complex designs: 3+ business days

Feel free to reach out for an assessment and quote for your design.

Contacting our team will

ensure a prompt response.

4. What are the advantages of CNC machining?

Rapid Prototyping: CNC machining excels in rapid prototyping, facilitating quick iterations and

testing of designs.

Efficient Production: The ability to produce full-scale production parts rapidly contributes to the

efficiency of CNC machining.

Precision and Accuracy: CNC machining ensures a high level of precision and accuracy in manufacturing,

meeting tight tolerances for CNC parts of varying sizes.

Tight Tolerance Machining: CNC machining allows for tight tolerance machining, ensuring consistent

adherence to exact specifications.

Flexibility: CNC machining offers flexibility across production volume, pricing, lead times, and the

choice of materials and finishes, providing a versatile solution for manufacturing needs.