|

|

[China]

Trade Verify

Address: Hengjiao Industry Zone, Hengjiao Village, Shijie Town, Dongguan, Guangdong, China

Contact name:Hafrey

Dongguan Yexin Intelligent Technology Co., Ltd. |

|

Verified Suppliers

|

|

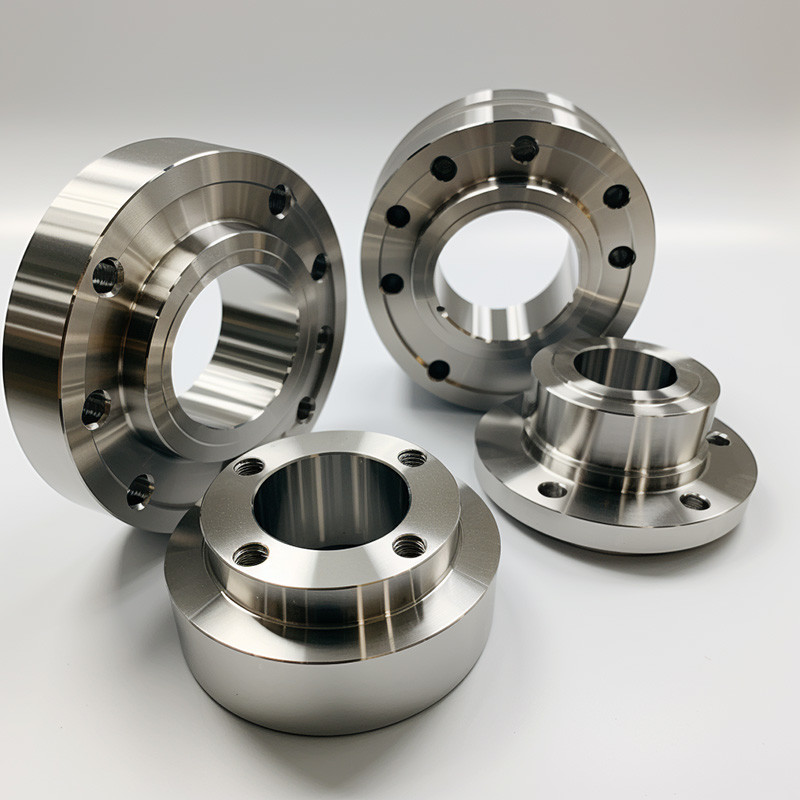

Our CNC machining services extend to the production of various parts, covering everything

from straightforward "as-machined" workholdings to complex geometric shapes.

Operating an extensive range of CNC mills and turning centers, our manufacturing facilities are

well-prepared to meet diverse requirements. Additionally, we have EDM and grinding capabilities

available upon request. Offering precision with tolerances as precise as 0.05 mm (0.0020 in),

we pride ourselves on efficient lead times, providing delivery options within a short span of 1

business days.

Product Details

The primary materials employed in the CNC machining process are predominantly metals.

These metals encompass alloy steel, carbon steel, cast iron, stainless steel, aluminum, copper,

magnesium, and zinc.

However, CNC machining is not limited to metals alone; it is also capable of machining plastic

parts and working with various materials, including ceramics, composites, thermoplastics,

and thermosets.

| Common Materials | |

| Name | Description |

| Aluminum | High machinability and ductility, good strength-to-weight ratio. |

| Stainless steel | High tensile strength, corrosion and temperature resistant. |

| Mild steel | High machinability and weldability, high stiffness. |

| Brass | Low friction, excellent electrical conductivity, golden appearance. |

| Copper | Excellent thermal and electrical conductivity. |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive and medical industries. |

| ABS | Common thermoplastic, impact resistant, easy to machine. |

| Nylon | Excellent mechanical properties, thermal, chemical and abrasion resistant. |

| POM | High stiffness, high accuracy, low friction, easy to machine. |

Post-processing and surface finishes for CNC machining

CNC-machined parts as they emerge from the machine often exhibit visible tool marks,

a feature that may not align with your specific part requirements.

Fortunately, there exists a multitude of post-processing techniques aimed at enhancing the

surface appearance and elevating attributes such as wear resistance, corrosion resistance,

and chemical resistance.

Methods like anodizing, bead blasting, and powder coating present viable options for refining

the final presentation of your custom parts, allowing you to achieve the desired surface

quality and performance characteristics.

| Surface Finishes | ||

| Name | Applicable to | Machining marks |

| As machined | Metals, Plastics | Visible, light surface scratches |

| Smooth machining | ||

| Fine machining | Metals | Slightly visible |

| Polishing | Metals | Removed on primary surfaces |

| Bead blasting | Metals | Removed for non-cosmetic, removed on primary surfaces for cosmetic |

| Brushing | Metals | |

| Anodizing Type II | Aluminum | |

| Anodizing Type III | Aluminum | Visible under anodizing |

| Black oxide | Copper, Stainless steel, Alloy steel, Tool steel, Mild steel | Visible |

| Powder coating | Metals | Removed |

| Brushed + electropolishing | Stainless steel | Removed on Primary surfaces |

Specialist Industries

CNC machining exhibits remarkable versatility in the manufacturing of products composed of

various materials, including glass, metal, plastic, wood, and custom-designed components.

Machinists harness the capabilities of CNC machining to produce a wide range of prototypes and

products for diverse industries, such as:

1. Aerospace:

CNC machining contributes to the manufacturing of precise

components for the aerospace industry,

meeting stringent requirements for quality and accuracy.

2. Automotive:

In the automotive sector, CNC machining is utilized to create

high-precision components for vehicles,

ensuring reliability and performance.

3. Hardware Startups:

Startups in the hardware industry benefit from CNC machining for

the production of prototypes

and custom-designed components, facilitating product development.

Company Profile

FAQ's

1. Which design file formats does We support for quoting?

To facilitate accurate and timely quoting, we only acknowledge 3D

CAD files in STL, STEP, or IGES

formats. For 2D drawings containing reference dimensions, we request submission in PDF format.

It's essential to provide comprehensive manufacturing information as part of the technical

documentation. Please note that informal communication channels such as SMS, Skype, and email

will not be considered valid for manufacturing purposes.

2. Do you provide Quick-Turn CNC Machining services?

Absolutely! We specialize in quick-turn parts with rapid lead

times, and many of our parts can be

delivered within 3-4 days. We also offer an expedite option, and our dedicated team collaborates

closely with you to ensure that we meet your most urgent deadlines.

3. What shipping terms do you operate under?

Our standard shipping terms are Ex Works (EXW) for both rapid

prototyping and regular production

orders. In this scenario, the customer takes charge of shipping, customs clearance, and any related

fees once the goods have been dispatched from our premises.

For express shipments, we employ Delivered Duty Unpaid (DDU). This places the responsibility on

the client to cover the import duty upon the goods' arrival at the specified destination.

4. What if I am not entirely satisfied with the parts I receive?

We stand behind the quality of our materials and workmanship, as

outlined in the terms of the initial

order and the information you provide. In the event of any disputes stemming from subjective

assessments, please bring them to the attention of our management.

They are committed to acting in good faith to ensure your complete satisfaction. Our ongoing

success is built on earning your trust in our capability to meet and surpass any reasonable expectations.