|

|

[China]

Trade Verify

Address: Hengjiao Industry Zone, Hengjiao Village, Shijie Town, Dongguan, Guangdong, China

Contact name:Hafrey

Dongguan Yexin Intelligent Technology Co., Ltd. |

|

Verified Suppliers

|

|

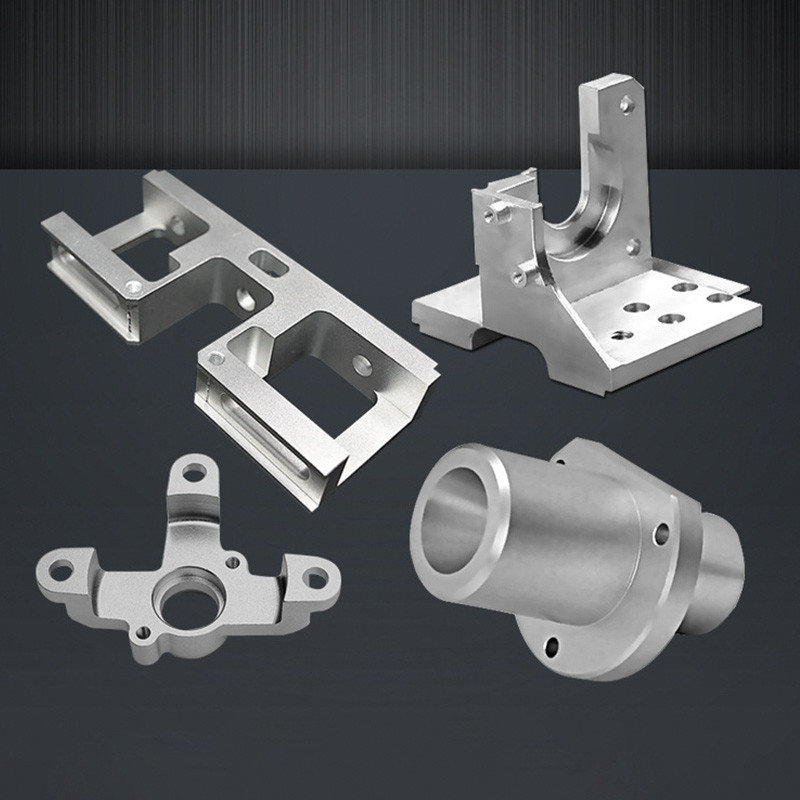

OEM Custom CNC Machining Milling Service Parts 6063 Aluminum Metal

Accessories Medical Device CNC Machining Aluminum Parts

CNC milling represents a machining process that seamlessly integrates computer numerical

control machining systems with multi-point cutting tools, often in the form of milling cutters.

As a pivotal branch of CNC machining, CNC milling entails securing the workpiece onto a

machine bed and methodically removing material from a solid block.

This meticulous process results in the fabrication of diverse products, encompassing materials

such as glass, metal, plastic, wood, and specialized materials.

Product Details

In custom milling projects, CNC machine shops can work with a variety of metals and plastics,

provided they are suitable for machining.

The prevalent choice for precision CNC machining is aluminum alloys, prized for their natural

corrosion resistance.

Aluminum stands out as a favored material for CNC milling machine prototypes, thanks to its

combination of strength and machinability, enabling the precise fabrication of intricate features

in a single prototype.

Among aluminum alloys, the 6000 series is the most frequently encountered in milling machine

shops. Stainless steel alloys are another common choice due to their resistance to corrosion

and wear.

Additionally, carbon steel, titanium, and nylon—a chemically resistant, robust, durable

thermoplastic—are materials often employed in CNC milling projects.

| Common Materials for CNC Machining | |

| Material | Properties |

| Aluminum | 2024: Good fatigue resistance and strength; excellent toughness at moderate to high strength levels; improved fracture toughness |

| 6061: Excellent machinability, low cost, and versatility | |

| 7075: High strength, hardness, low weight, and heat tolerance | |

| Brass | Versatile and highly attractive copper/zinc alloy with warm yellow color accommodates severe forming/drawing |

| Copper | High ductility and high electrical and thermal conductivity; develops attractive blue-green surface patina over time |

| Stainless Steel | Excellent machinability and outstanding uniformity; good workability and weldability, high ductility and formability |

| Steel Alloy | Mix of chromium, molybdenum, and manganese yields toughness, good torsional and fatigue strength |

| Steel Mild Low Carbon | High machinability and weldability, high stiffness; good mechanical properties, machinability, and weldability at low cost |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive, and medical industries |

| ABS | Excellent impact resistance, good mechanical properties, susceptible to solvents |

| Nylon | Excellent mechanical properties, high toughness, poor moisture resistance |

| POM | High stiffness, excellent thermal & electrical properties, relatively brittle |

| CNC Milling Tolerances | ||

| Limits for nominal size | Plastics | Metals |

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.10mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.20mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.30mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.50mm |

| Over 2000mm to 4000mm | ±2.0mm | |

*Please clearly indicate tolerances for nominal sizes below 0.5mm on your technical drawing. | ||

What kinds of parts can you make with CNC milling machines?

CNC milling machines let operators create complex designs with very tight tolerances.

As a result, it is one of the most accurate manufacturing techniques to date.

Here’s a look at the products you can create:

1. Aerospace components such as landing gear components, fuselage

structures

2. Components for the automotive industry such as control panels,

axles, car molds

3. Consumer electronics components such as enclosures

4. Medical components such as surgical instruments, orthotics

5. Oil and gas machine parts such as valves, rods, pins

6. Prototyping and modeling

7. Sculptures

8. Furniture

9. Woodworking

Company Profile

FAQ's

1. How much do CNC machining materials cost?

The cost of materials in CNC machining can fluctuate significantly due to the extensive array

of available options.

Each material carries its unique price tag, and the inherent physical properties of each material

play a substantial role in determining machining costs.

For those seeking to manufacture metal components, Aluminum 6061 stands out as the most

cost-effective choice. On the other hand, ABS ranks as the most budget-friendly option among

materials.

As for the influence of machining complexity on costs, stainless steel serves as an illustrative

example. Its inherent hardness, surpassing that of aluminum, renders it more challenging to

machine, consequently elevating the overall machining expenses.

2. What are standard machining tolerances?

Typical machining tolerances fall within the range of ± 0.005 inches or 0.13 millimeters.

Tolerances represent the allowable variation for a specific dimension.

For instance, if a CNC machining tool has a tolerance of ± 0.01 millimeters, it means that the tool

can deviate by 0.01 millimeters in each cut.

When provided with a drawing, Our CNC machining service can achieve CNC parts with tolerances

as tight as ± 0.0002 inches. In the absence of a drawing, all CNC parts are manufactured according

to our ISO 2768 medium standard.

We can also work to even tighter tolerances, such as ± 0.025 millimeters or ± 0.001 inches,

when an engineering drawing specifies critical features.

3. What is the typical delivery time and quotation process?

Delivery time is determined based on the complexity of the parts.

For low-complexity parts, the lead time is typically 2-3 days. As the complexity of the parts

increases, the lead time can range from 2-5 days. High-complexity parts may require a lead

time of 5-15 days.

Similarly, the quotation process varies depending on the complexity

of your design.

Quotes can be provided in as little as 1 business day, or it may take 3 or more business days for

more intricate designs.

If you have a design that you would like our team to assess and

provide a quote for, please don't

hesitate to contact us.