Senlan Precision Parts Co.,Ltd. |

|

Verified Suppliers

|

|

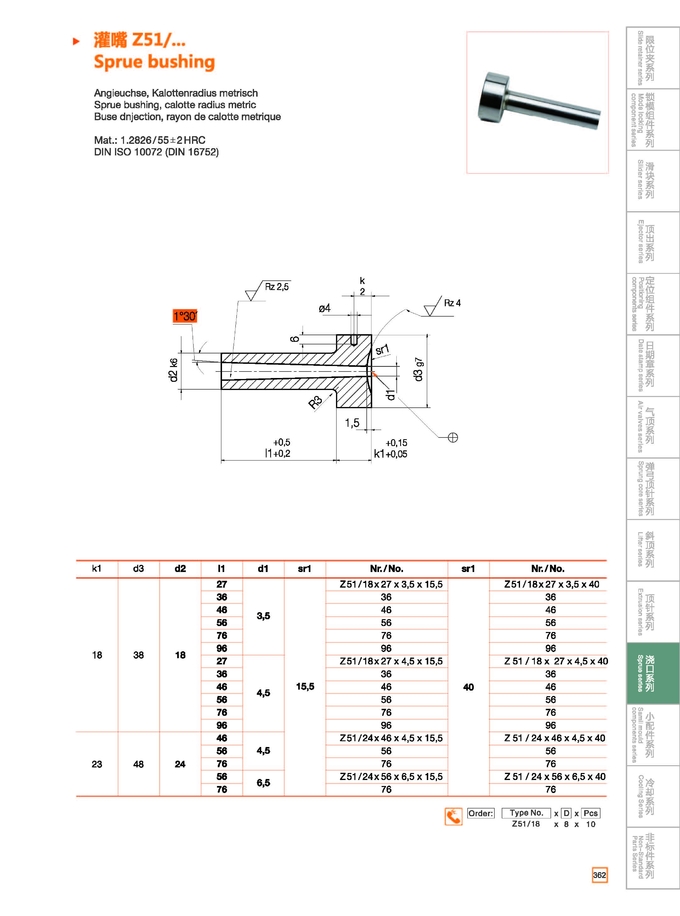

Z51 HASCO SKD61 Sprue Bushing Mold Components For Plastic Mould

Why sprue bush is important in product?

It connects pouring basin to the runner. In many cases it controls

the flow of material into the mold. During casting or molding, the

material in the sprue will solidify and need to be removed from the

finished part. It is usually tapered downwards to minimize

turbulence and formation of air bubbles.

Feature of Sprue Bush

| Material | Inner Hardness | Surface Hardness | Heat Treatment |

| S45C | SR HRC50~55 | Partial | |

| SKD11 | HRC58~62 | HRC58~62 | Vacuumed |

| SKD61 | HRC34~38 | HV900~1100 | Nitrided |

| HRC50~54 | HRC50~54 | Vacuumed | |

Manufacturing Equipments

OD Grinding,ID Grinding, CNC Milling, CNC turning, Wire cutting, EDM, Drilling, etc.

Delivery time of Sprue Bush

7-15 days, depending on quantity.

Payment terms

50% T/T before production, 50% TT before shipment.

Inspection Equipments

CMM, 2.5D, Projector, Calipers, Hardness Tester, Micrometer,

Altimeter, etc.

Tolerance of Sprue Bush

+-0.05mm, Depends on customer’s requirements.

Drawing Format of Sprue Bush

PDF/DWG/DXF/IGS/STEP,etc

Certificate

ISO9001-2008

Packaging

Inner packing with recycle plastic box and anticorrosive oil, outer

with sponge and PE bags, or as customer's requirements.

Application field

Parts are used on cosmetic packaging, medical, Daily necessities packaging, automobile etc.

Our advantages

(1). Competitive price with good quality

(2). Low MOQ (10pcs is kindly accepted in some special conditions)

(3). Customized size and OEM available

(4). Precise tolerance: +/-0.05mm

(5). 100% inspection

Sales team

Professional sales team make sure we could offer you great service

Corporate Culture

Our mission: help our costumer boost its competitiveness,help our employees be successful and rich,create more values for our society.

Our vision: become first-class enterprise in Mould Accessory Industry worldwide.

Our tenet: responsibility, technology,quality,punctuality,honesty,service.

Management concept:Cohering hearts and minds with cooperate-culture,regularizing behaviour with systems and regulations.

Work shop

With high precision machining equipments and experienced technicians, make sure all the dimensions meet tolerance requirement.

Inspection Equipment

Complete QC system and strict test means ensure the high grade of product quality.

Main products

Q:Are you trading company or manufacturer?

A:We are factory.

Q:How long is your delivery time?

A: Generally it is 10-20 days if the goods are not in stock, it is

according to quantity.

Q:What is your quote elements?

A:Product standard: model + size, or customer Drawing.

Q:How can you ensure the quality?

A:We have QC department to control the quality from the begining of

production until goods finish.

Q:If you make poor quality goods,will you refund our fund?

A:As a matter of fact, we wont take a chance to do poor quality

products. Meanwhile, we manufacture goods quality products until

your satisfaction.

Q. Do you test all your goods before delivery?

A: Yes, we have 100% QC test and QC report for mold parts before

delivery.

Q. Can you produce according to the samples or drawings?

A: Yes, we can produce parts by your samples or technical drawings.