Shanghai Anfeng Lifting & Rigging LTD. |

|

Verified Suppliers

|

|

The sling assemblies are produced comply with EN 13414-1: 2003, EN 13411-3: 2004, GB/T 16762-2009, GB/T 14737-2009 requirements.

You will often see equipment of this nature being swaged, which means that the end has been folded back on itself, and spliced into the rope.

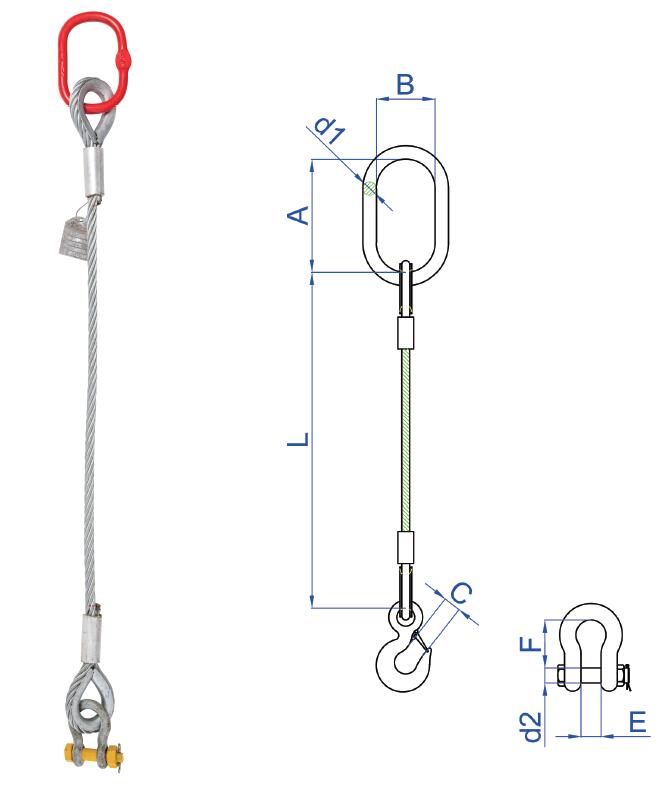

| Product Code | Rope dia. (mm) | 6x37 (a) + IWRC, 1770 MPa WLL (t) | Master Link dimension d1×A×B (mm) | Equipped with | ||||

| Hook | Shackle | |||||||

| Load capacity | Gape C | Load capacity | dimension d2×E×F | |||||

| (t) | (mm) | (t) | (mm) | |||||

| CSSWH11 | CSSWS11 | 11.0 | 1.4 | 16×140×80 | 1.5 | 24.6 | 1.5 | 13×19×42 |

| CSSWH12 | CSSWS12 | 12.0 | 1.66 | 16×140×80 | 2.0 | 26.9 | 2.0 | 16×21×47 |

| CSSWH13 | CSSWS13 | 13.0 | 1.95 | 16×140×80 | 2.0 | 26.9 | 2.0 | 16×21×47 |

| CSSWH14 | CSSWS14 | 14.0 | 2.27 | 16×140×80 | 3.0 | 30.2 | 3.25 | 19×27×60 |

| CSSWH15 | CSSWS15 | 15.0 | 2.6 | 16×140×80 | 3.0 | 30.2 | 3.25 | 19×27×60 |

| CSSWH16 | CSSWS16 | 16.0 | 2.96 | 16×140×80 | 3.0 | 30.2 | 3.25 | 19×27×60 |

| CSSWH18 | CSSWS18 | 18.0 | 3.75 | 20×160×95 | 4.5 | 38.1 | 4.75 | 22×32×71 |

| CSSWH20 | CSSWS20 | 20.0 | 4.62 | 20×160×95 | 7.0 | 45.0 | 4.75 | 22×32×71 |

| CSSWH22 | CSSWS22 | 22.0 | 5.6 | 26×190×110 | 7.0 | 45.0 | 6.5 | 25×37×84 |

| CSSWH24 | CSSWS24 | 24.0 | 6.7 | 26×190×110 | 7.0 | 45.0 | 8.5 | 28×43×95 |

| CSSWH26 | CSSWS26 | 26.0 | 7.8 | 26×190×110 | 11.0 | 61.0 | 8.5 | 28×43×95 |

| CSSWH28 | CSSWS28 | 28.0 | 9.1 | 26×190×110 | 11.0 | 61.0 | 9.5 | 32×46×108 |

| CSSWH30 | CSSWS30 | 30.0 | 10.4 | 32×230×130 | 11.0 | 61.0 | 12.0 | 35×52×119 |

| CSSWH32 | CSSWS32 | 32.0 | 11.8 | 32×230×130 | 15.0 | 66.6 | 12.0 | 35×52×119 |

| CSSWH34 | CSSWS34 | 34.0 | 13.4 | 32×230×130 | 15.0 | 66.6 | 13.5 | 38×57×131 |

| CSSWH36 | CSSWS36 | 36.0 | 15.0 | 38×275×150 | 15.0 | 66.6 | 17.0 | 42×61×148 |

| CSSWH38 | CSSWS38 | 38.0 | 16.7 | 38×275×150 | 22.0 | 86.6 | 17.0 | 42×61×148 |

| CSSWH40 | CSSWS40 | 40.0 | 18.5 | 38×275×150 | 22.0 | 86.6 | 25.0 | 51×73×177 |

| CSSWH42 | CSSWS42 | 42.0 | 20.4 | 38×275×150 | 22.0 | 86.6 | 25.0 | 51×73×177 |

| CSSWH44 | CSSWS44 | 44.0 | 22.4 | 45×340×180 | 30.0 | 101.6 | 25.0 | 51×73×177 |

| CSSWS46 | CSSWS46 | 46.0 | 24.5 | 45×340×180 | 30.0 | 101.6 | 25.0 | 51×73×177 |

| CSSWH48 | CSSWS48 | 48.0 | 26.6 | 45×340×180 | 30.0 | 101.6 | 35.0 | 57×83×197 |

| CSSWH50 | CSSWS50 | 50.0 | 28.9 | 45×340×180 | 30.0 | 101.6 | 35.0 | 57×83×197 |

| CSSWH52 | CSSWS52 | 52.0 | 31.3 | 45×340×180 | 37.0 | 108.0 | 35.0 | 57×83×197 |

| CSSWH54 | CSSWS54 | 54.0 | 33.7 | 50×350×190 | 37.0 | 108.0 | 35.0 | 57×83×197 |

| CSSWH56 | CSSWS56 | 56.0 | 36.3 | 50×350×190 | 37.0 | 108.0 | 55.0 | 70×105×267 |

| CSSWH58 | CSSWS58 | 58.0 | 38.9 | 50×350×190 | 45.0 | 120.0 | 55.0 | 70×105×267 |

| CSSWH60 | CSSWS60 | 60.0 | 41.6 | 56×400×200 | 45.0 | 120.0 | 55.0 | 70×105×267 |

| Note: 1. Reference standard: EN 13411-3: 2003, EN 13411-3: 2004, GB/T 16762-2009, GB/T 14737-2009. 2. Surface treatment of wire ropes can be galvanized and grease free, galvanized with grease and uncoated with grease. 3. The wire rope structure, tensile strength and working load limited could be customized according to customer's request. 4. Safety factor of the rigging is 5:1. 5. Safety factor of the Master Link and Hook is 4:1. 6. Safety factor of the shackle is 6:1. | ||||||||