Share Group Limited |

|

Verified Suppliers

|

|

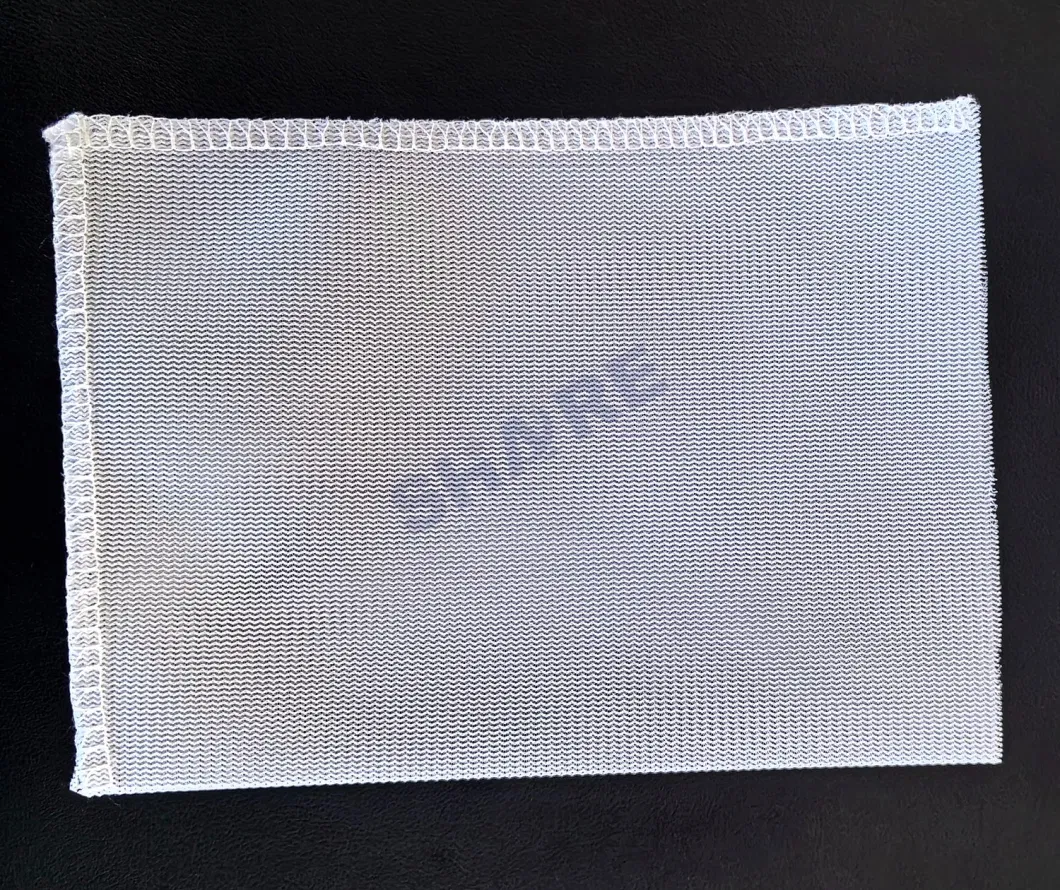

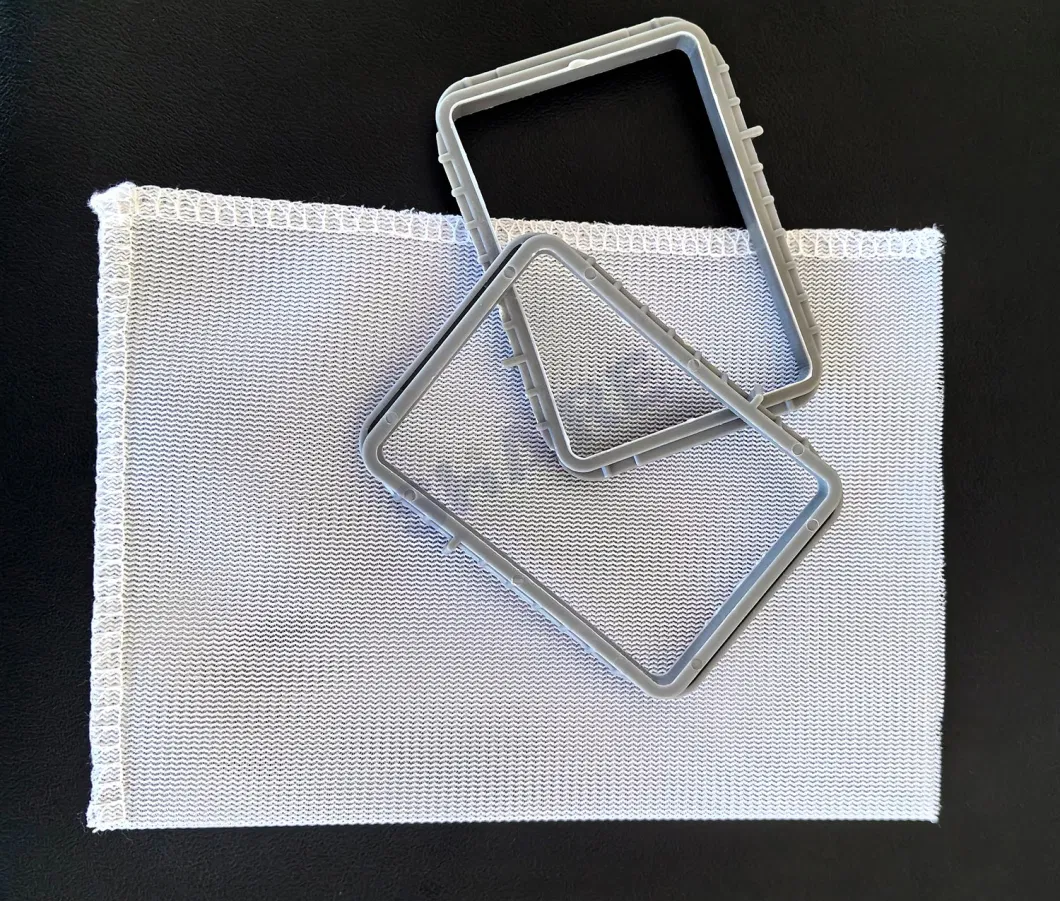

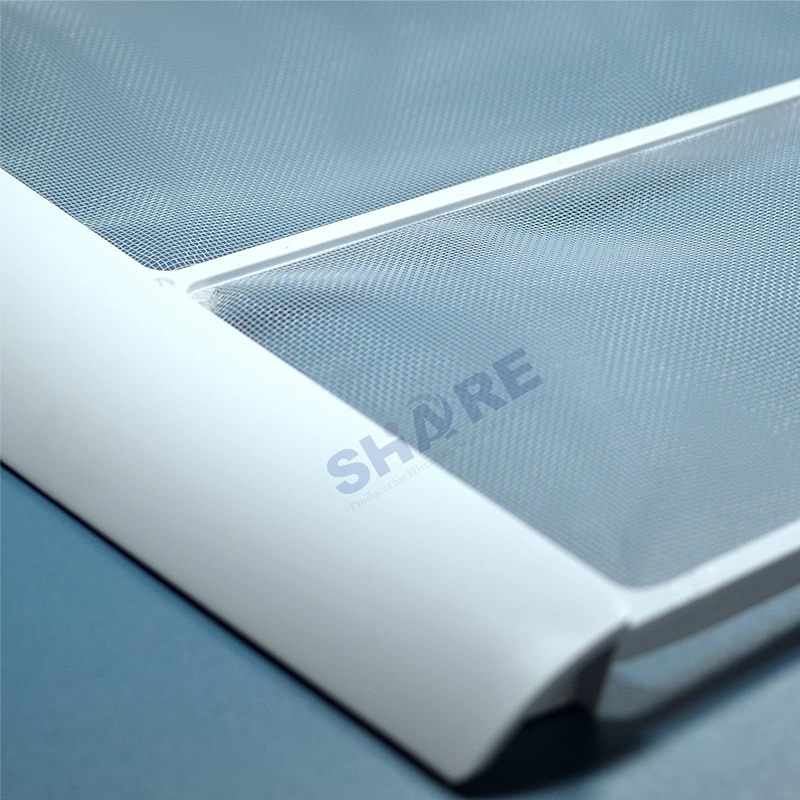

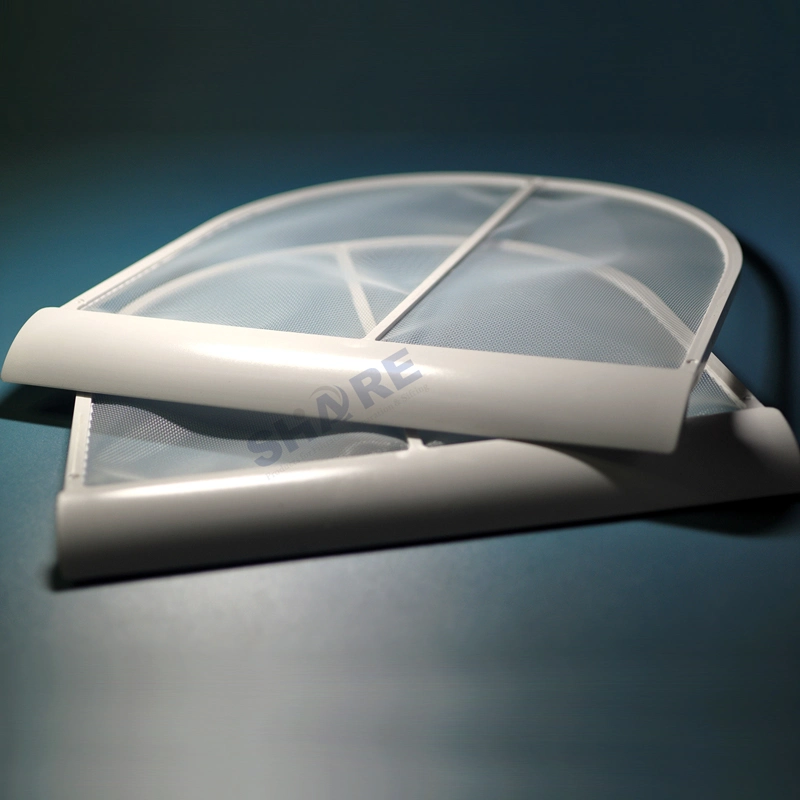

| Item Name | Washing Machine Lint Filter Trap, Wear and Tear Resistant Optimal Soft Net |

| Manufacturer | Taizhou Share Filters Co., Ltd |

| Brand | SHARE FILTERS |

| Color | As the photo shows or any Pantone colors |

| Dimension and Size | Customizable due to customer needs |

| Plastic Materials | ABS, PC/ABS, PP, PC, POM, Nylon 6, Nylon 66 etc. |

| Filter Materials | Ultra fine nylon soft net |

| Quality Control | Visual inspection, optical or pressure sensitive equipment and automated 3D image-inspection equipment, self-inspections, spot inspections, final inspections |

| Application | Washing machine |

Dryer Lint Filter

The first step in producing injection molded products is to manufacture the molds. Accurate mold is crucial to the success of the injection molding process, as it directly impacts the quality and consistency of the molded products.. Our process for producing molds is as follows:

Once the mold-making process is complete, we will produce several

pre-production samples for testing. If the dimensions are correct,

we will then send these samples to customers for their final

confirmation. In the event of a test failure, we will either modify

the mold or adjust the molding parameters to create new samples and

conduct further testing.

Once customers approval our samples, we will proceed with

purchasing raw materials and conducting quality inspections.

Subsequently, we will carry out material mixing, molding, and

trimming, with multiple inspection checkpoints during the

production process. Finally, we will arrange for assembly and

packaging. When the entire order is ready, we will provide the

packing list to the customer to coordinate the shipment.

SHARE excels in handling OEM orders. With our team of experienced product engineers and mold developers, we are proficient in assisting you with rapid prototyping and on-demand production services for plastic molded products.

Please don't hesitate to reach out to us via phone or email if you require any information regarding your filtration application. Our team of experts is dedicated to assisting you with our innovative and dependable solutions.

Lint filters are packed into sealed PE bags. The label contains the following standard information:

| Port to Port | Door to Door | |

| Express(DHL,UPS,FEDEX, EMS) | 1 - 5 days | |

| Air Freight | 1 - 5 days | 4 - 10 days |

| Sea Freight(FCL) | 15 - 30 days | 20 - 35 days |

| Sea Freight(LCL) | 15 - 30 days | 22 - 37 days |

Who we are?

Established in 1983, SHARE has been a leading manufacturer,

developer and provider of industrial filtration solutions in China.

Filtration is our passion. Innovation is our value. Customer is our

partner. We have been active in filtration solutions for 40 years

and working together with our customers to design and manufacture

thousands of specific filtration solutions. Customers trust SHARE

products for customization, full traceability and lot-to-lot

accuracy.

What we do?

Our product range:

1. Precision woven filter screen mesh: nylon (polyamide), polyester, polyethylene, polypropylene,

stainless steel etc. Mesh opening can vary from 1um to 4000um.

2. Fabricated mesh: converting filter meshes into various sizes and shapes such as

rolls, discs, stampings, tubes, ribbons, cut-to-size sections,

pleated elements, bags, and many more.

3. Molded filters: molding mesh with plastic to create different types of plastic

molded filters.

4. Filtration solutions: with its profound understanding of applications and long-standing

experience, SHARE supports customers to design, develop and

manufacture of achieving optimal filtration results in their

industrial processes.

1. Who are we?

Taizhou Share Filters Co., Ltd is a China-based factory established

in 1983. We specialize in filter media with rating from 3um to 4000um (woven

filters), converting meshes filters into various sizes and shapes,

and molding mesh with plastic to create different types of plastic

filters.

2. Where is your factory located? How can I visit there?

We are in Taizhou city, Zhejiang province China. By train, we are

one hour away from Hangzhou and two hours away from Shanghai.

3. Can I get free samples and how long can you deliver them?

We are pleased to provide you with free samples for your

evaluation, which will be sent to you within 2 days. Please feel

free to reach out to us for samples.

4. How long does a quotation take?

In most cases, we respond within 2 days. If something in RFQ need

be confirmed, we will promptly notify you soon.

5. How quickly can I get my order finished?

The production lead time is dependent on the quantity. Typically,

it takes 5 to 15 working days for us to complete mass production

once you have placed the order.

6. What about your quality control?

By visual inspection, optical or pressure sensitive equipment and

automated 3D image-inspection equipment, our production operators conduct self-inspections at every stage of

the process. Additionally, we have spot inspections and final

inspections carried out by our Quality Control (QC) team.

7. What kind of payment terms do you accept?

T/T and LC and more.

8. What's your largest advantage?

One of our core competencies is the production of high precision

injection molded plastic filters with professional technical team

and quality guarantee and management for more than 30 years.

9. Can plastic molded filter specifications be customized?

Absolutely, at SHARE, the materials, dimensions, shape,

construction method, mesh size, and applications of the filters are

all fully customizable to meet your specific requirements.

10. Regarding custom-made filter orders, do you need drawings for

production?

If you have drawing (2D, 3D both available. 2D like PDF, CAD, JPG etc. 3D like STP, IGS,

STL, SAT, PRT, IPT etc.) it'll be helpful for us to proceed with the production.

However, if you don't have any drawing, don't worry. SHARE can work

with you to create a drawing based on a description or image of the

filters you have in mind. We can get started without any drawings

initially.