Share Group Limited |

|

Verified Suppliers

|

|

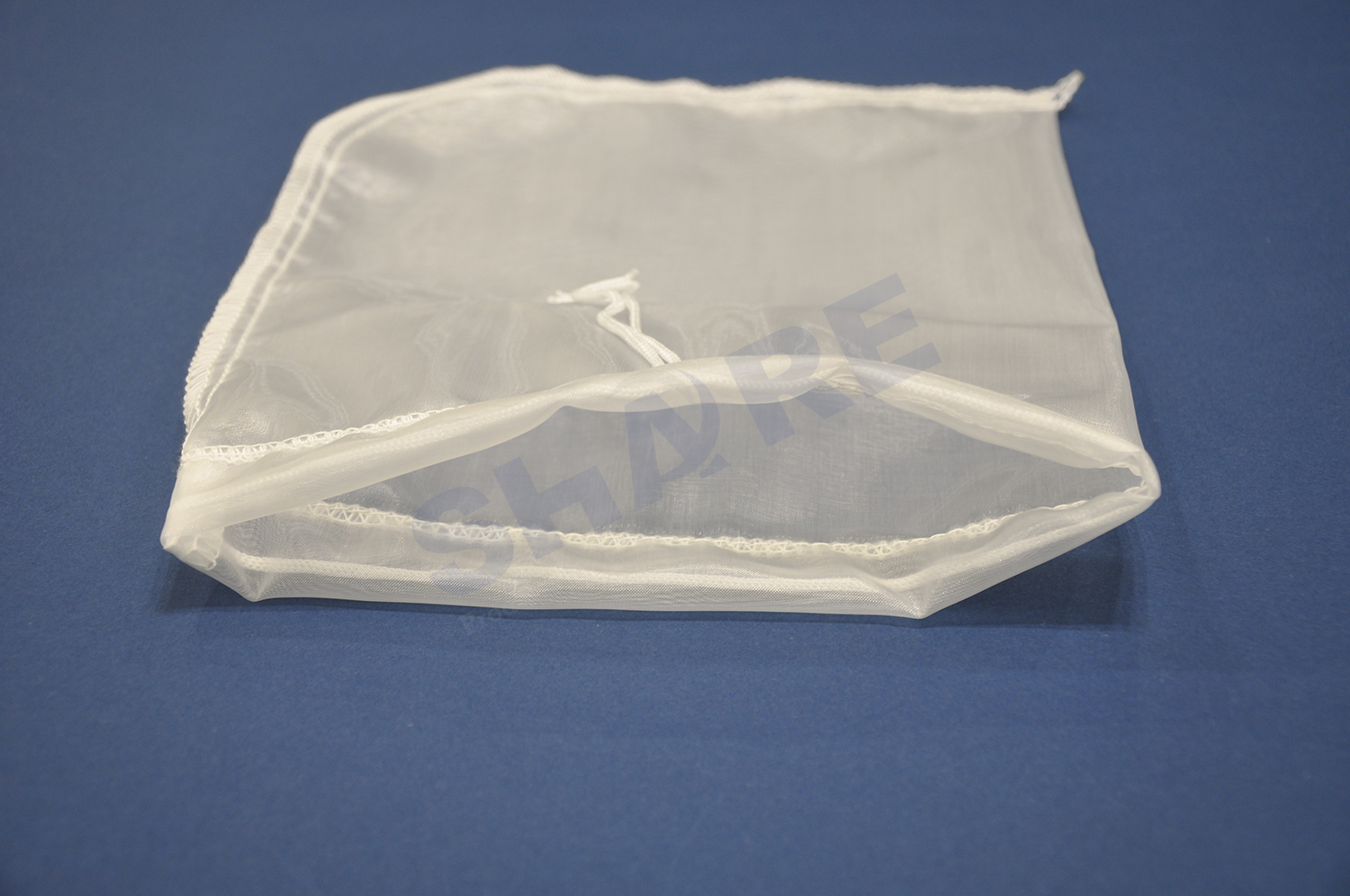

275 Micron Nylon Mesh Bag Custom-Tailor For Honey Stocking Strainer

The nylon filter mesh is the most suitable filter media to filter the honey from the impurities present inside the honey deriving from the honey extraction. These impurities such as pieces of wax, small fragments of wood or organic parts of insects. The nylon filter mesh bag is especially designed to provides a very effective filttation for honey.

Once the honey has been extracted, the honey must then be filtered before passing to the ripener for decanting. The nylon mesh stocking bag allows a very effective filtering, specially designed for honey.

Nylon Filter Mesh Specification Options for Honey Filter Bag

| Meterial | Monofilament (Single Filament) nylon mesh |

| Thread Diameter | From 30 micron to 350 micron |

| Mesh Opening | From 25 micron to 1000 micron |

| Open Area | From 19.5% to 57% |

| Weave Type | Plain Weave |

| Treatment | Washing, Heat-setting |

| Dimension | Customized |

| Products Type | Sell by rolls, or can cut in custom size, weld bag, sewn bag |

The Benefit Features of Nylon Filter Mesh Used for Honey Filtration:

Nylon Filter Mesh Specification for Honey Filtration

| Ref. No. | Mesh Count | Thread Diam. | Mesh Opening | Opening Area | |

| mesh/cm | mesh/inch | µm | µm | % | |

| JPP7 | 7 | 18 | 350 | 1079 | 57 |

| JPP8 | 8 | 20 | 350 | 900 | 52 |

| JPP9 | 9 | 24 | 250 | 860 | 60 |

| JPP10 | 10 | 25 | 300 | 700 | 49 |

| JPP12 | 12 | 30 | 250 | 583 | 49 |

| JPP12 | 12 | 30 | 300 | 533 | 41 |

| JPP14 | 14 | 35 | 300 | 414 | 34 |

| JPP16 | 16 | 40 | 200 | 425 | 46 |

| JPP16 | 16 | 40 | 250 | 375 | 36 |

| JPP20 | 20 | 50 | 150 | 350 | 49 |

| JPP20 | 20 | 50 | 200 | 300 | 36 |

| JPP24 | 24 | 60 | 150 | 267 | 41 |

| JPP28 | 28 | 70 | 120 | 237 | 44 |

| JPP30 | 30 | 76 | 120 | 213 | 41 |

| JPP32 | 32 | 80 | 100 | 213 | 46 |

| JPP36 | 36 | 90 | 100 | 178 | 41 |

| JPP40 | 40 | 100 | 100 | 150 | 36 |

| JPP43 | 43 | 110 | 80 | 152 | 43 |

| JPP48 | 48 | 120 | 80 | 130 | 38 |

| JPP56 | 56 | 140 | 60 | 120 | 44 |

| JPP59 | 59 | 150 | 60 | 110 | 42 |

| JPP64 | 64 | 160 | 60 | 100 | 37 |

| JPP72 | 72 | 180 | 50 | 90 | 41 |

| JPP80 | 80 | 200 | 50 | 75 | 36 |

| JPP100 | 100 | 250 | 40 | 60 | 36 |

| JPP120 | 120 | 305 | 40 | 43 | 25 |

| JPP130 | 130 | 330 | 40 | 37 | 23 |

| JPP140 | 140 | 355 | 30 | 38 | 33.7 |

| JPP150 | 150 | 381 | 30 | 34 | 30.25 |

| JPP165 | 165 | 420 | 30 | 28 | 20.7 |

| JPP180 | 180 | 460 | 30 | 25 | 19.5 |

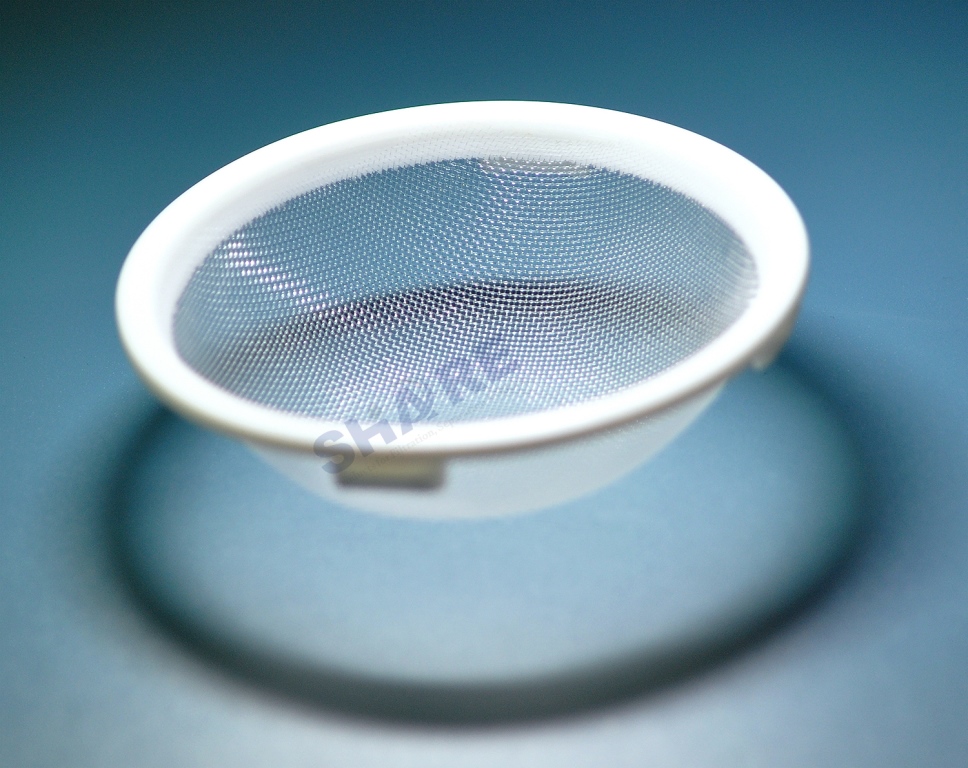

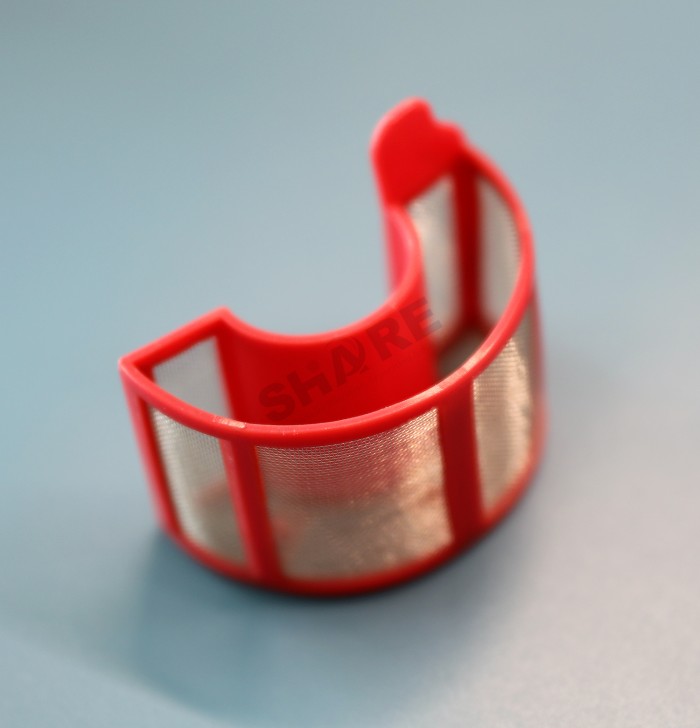

Share Filters Other Products for Food Contact

Share Filters Manufacture Capabilities

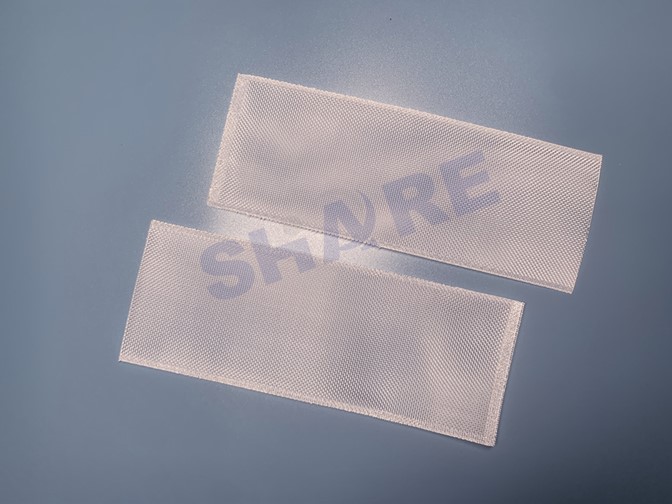

Share Filters in-house capabilities include enhanced processing such as filter mesh slitting, punching, tubing, cutting,

injection molding and finishing of products. Share Filters can supply the nylon filter mesh, polyester mesh,

PP filter mesh, metallic mesh in different types to meet customs' filtration demands.

|  |  |

| Share Filter synthetic meshes are made from a variety of materials such as polyamide, polyester, polypropylene, etc. You can order by the roll or in pre-cut shapes. | Ultrasonic and heat slitting is also used for manufacturing filtler mesh strips and resulting in a closed edge with very little material build up at the edge. | Our cutting method include Laser cutting, Cold cutting, Heatt cutting, Punching. Professional cutting using custom-made tools that will not damage the materials. |

|  |  |

| Sonic welding are accurate, clean. precision, sleeves and bags for blood filtration, biopsy bag and rosin bag are examples of applications that benefit from this technology. | Share Filters sewing mesh filter products are carried out by highly skilled and experienced machinists, which ensure you get the right level of consistent quality. | Custom plastic moulded filters combine precise filter mesh with polymer plastic. Injection moulding can take many forms and Share Filters is fully capable to help develop and produce the filters that will best suit your needs. |

About Us

Share Filters has over 20 years of experience developing and manufacturing filter mesh and custom product for our customer's screen and filtration needs. We can offer the filter mesh and filter components services including slitting, cutting, welding, sewing and injection molding. Our customer base comes from a wide variety of industries including – Automotive, Home appliances, Food and beverage, Milling, Medical, Life Science and laboratory, Electronical as well as more general engineering, giving us a wealth of experience in many areas.

Industries We Serve

|  |  |  |  |  |

| Automotive | Appliance | Medical | Food & Beverage | Agriculture | Environmental |