Share Group Limited |

|

Verified Suppliers

|

|

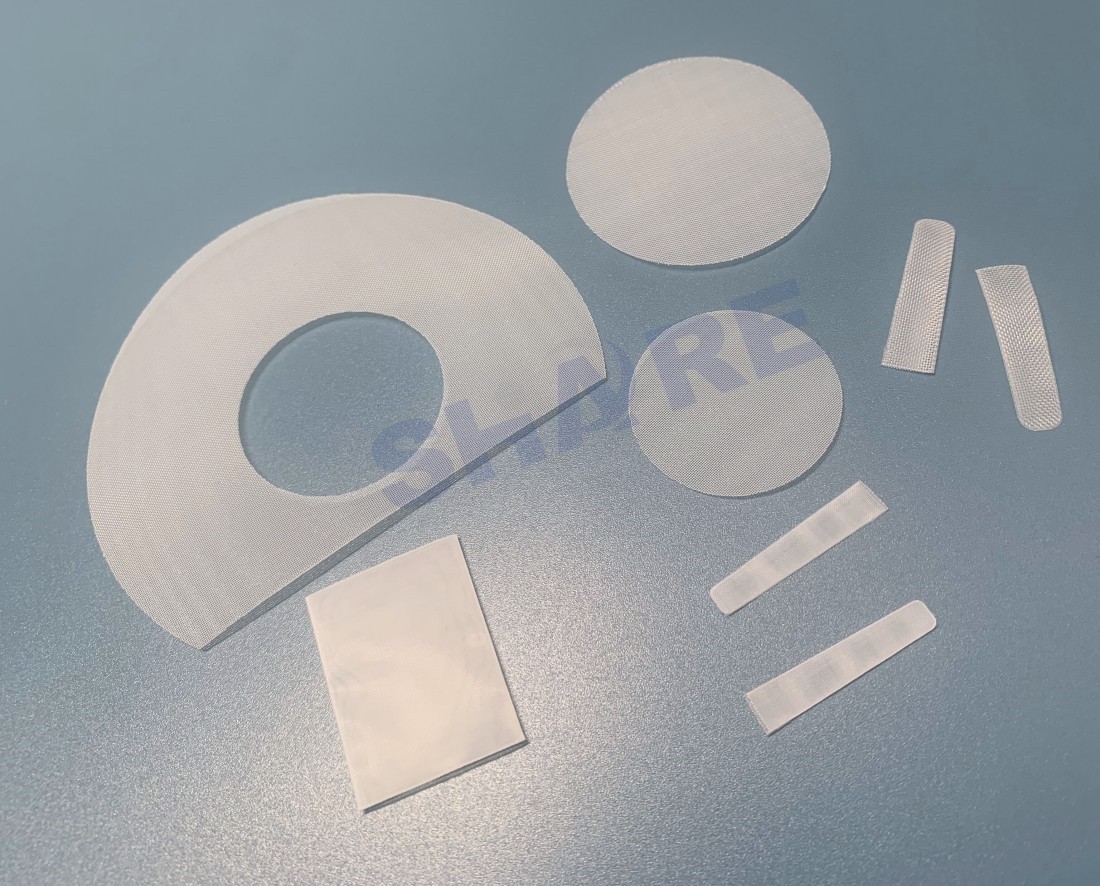

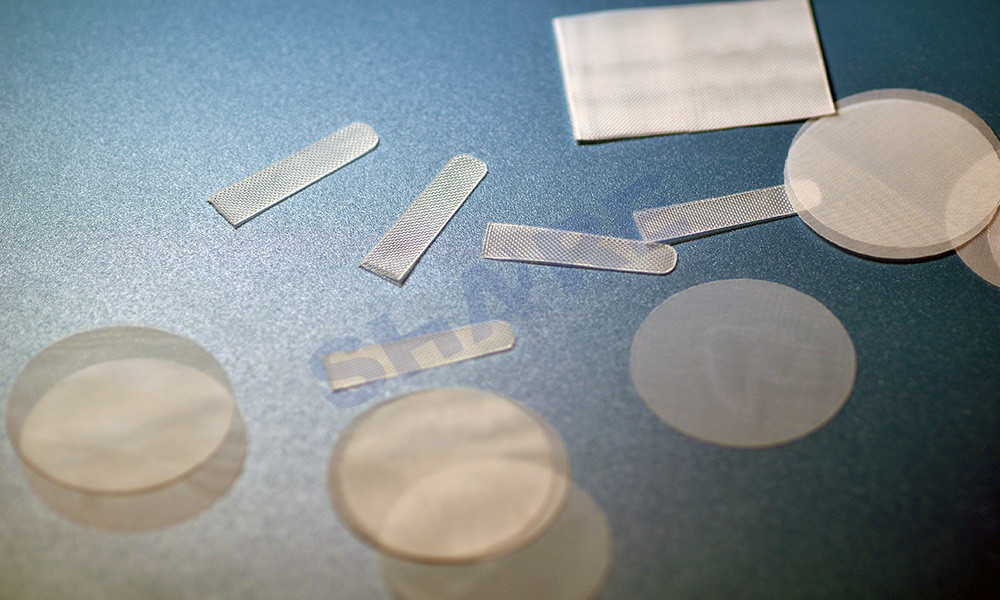

55 Micron Nylon Filter Mesh Cut Discs Shapes Sheets In Tight Tolerance

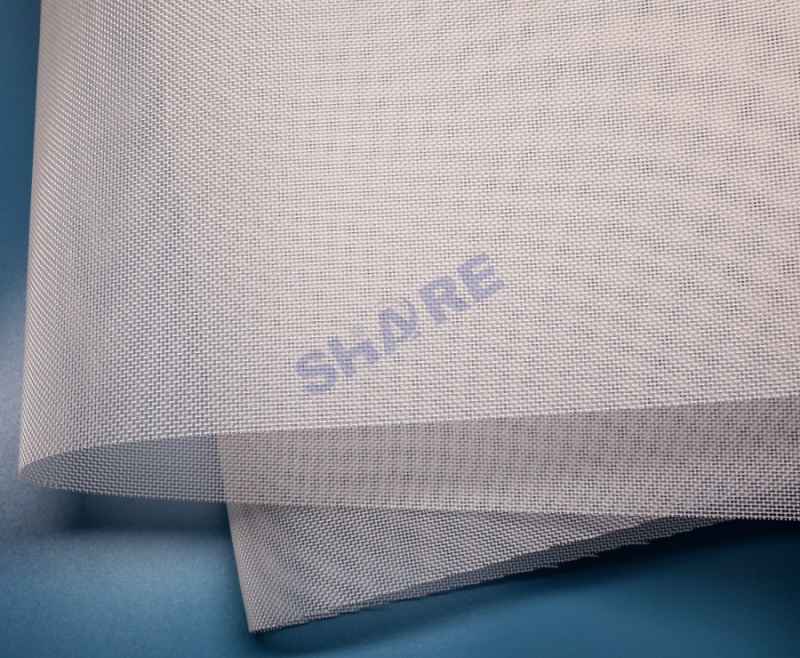

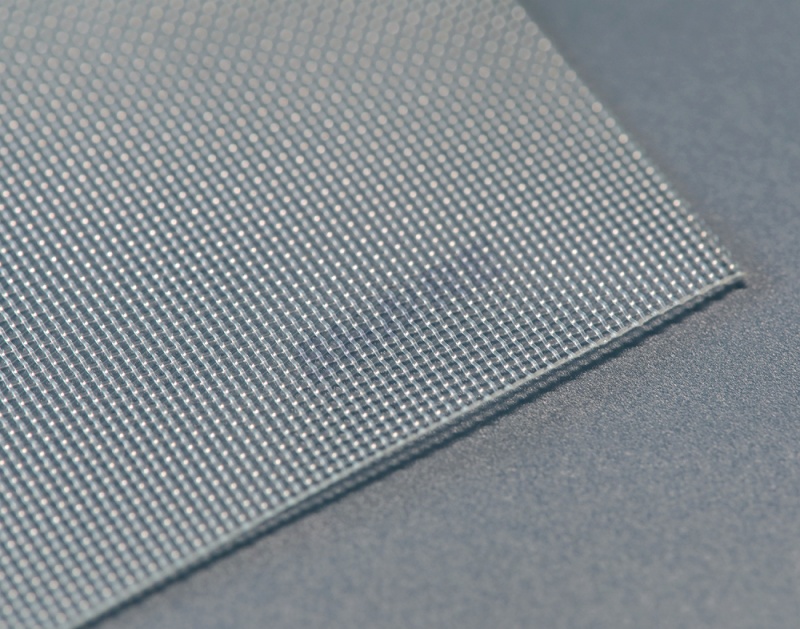

| Share Filters is a Chinese primary supplier in the development, production and sale of high precision monofilament filter meshes and mesh filter components for variety of industrial applications. The main filter meshes include in polyamide mesh, polyester mesh, polypropylene mesh and stainless steel. Primary Treatments includes Dyeing, Resin Coating, Corona Treatment, Calendering, Sputtering are optional procedures that chemically enhance the performance of the mesh or manipulate its appearance in various ways.

Thanks to advanced processing equipments and rich experience, Share Filters can provide filter meshes cut to size, lot-to-lot consistency and high quality custom fabricated components, like filter mesh sheets in single or double layers, shapes are cut polygons or irregular. We'll assist you to choose the best fabrication technology according the filter media. |

| Benifits of Share Filters Nylon Mesh Pre-Cutting Sheets and Shapes:

|

Share Filtes' Filter Mesh Pre-cut Sheets and Shapes Options

| Filter media | Nylon mesh, polyester mesh, PP mesh, stainless steel mesh |

| Micron rating | 3μm - 3233μm | |

| Mesh fabrication | Slitting, laser cutting, ultrasonic cutting, punching | |

| Specification | Custom design |

| Nylon Filter Mesh Often compared with polyester, nylon mesh has higher water absorption rate, unrivaled strength resistant to cyclic deformation, is robust against friction and bending, and is highly elastic and wrinkle-resistant as it's characteristics. It also features resistance to chemicals and oils, as well as being resistance to alkalis.

Polyester Filter Mesh Polyester is one of the strongest fibers and remains resistant even if it gets wet and exposed to friction. Its low moisture absorbency prevents it from expanding, contracting, becoming wrinkled, and it also features resistance to chemicals, as well as being dimension stability.

Polypropylene Filter Mesh Polypropylene mesh is chemical resistant and non-absorbent, with good weather, acid and alkaline resistance

Stainless Steel Filter Mesh Stainless steel filter mesh is with the following benefits: corrosion resistance, strength and durability, high temperature resistance, versatility, easy maintenance and cleanliness, environmental friendliness |

How To Select the Right Filter Mesh? You Can Follow These Points.

|

|

Nylon Filter Mesh Specification

| Fabric number | Mesh count | Thread diameter | Mesh opening | Open area | Fabric thickness | Weight | |

| No. | mesh/cm | mesh/inch | micron | micron | % | micron | g/m2 |

| JPP2 | 2.3 | 6 | 1000 | 3233 | 58.3 | 1900 | 412 |

| JPP3 | 3.1 | 8 | 900 | 2300 | 51.3 | 1700 | 450 |

| JPP4 | 4 | 10 | 550 | 1950 | 61 | 950 | 262 |

| JPP5 | 5 | 12 | 500 | 1500 | 56 | 850 | 271 |

| JPP6 | 6 | 16 | 400 | 1267 | 58 | 780 | 208 |

| JPP7 | 7 | 18 | 350 | 1079 | 57 | 675 | 186 |

| JPP8 | 8 | 20 | 350 | 900 | 52 | 685 | 212 |

| JPP9 | 9 | 24 | 250 | 860 | 60 | 455 | 145 |

| JPP10 | 10 | 25 | 300 | 700 | 49 | 576 | 195 |

| JPP12 | 12 | 30 | 250 | 583 | 49 | 470 | 162 |

| JPP12 | 12 | 30 | 300 | 533 | 41 | 585 | 234 |

| JPP14 | 14 | 35 | 300 | 414 | 34 | 595 | 273 |

| JPP16 | 16 | 40 | 200 | 425 | 46 | 370 | 139 |

| JPP16 | 16 | 40 | 250 | 375 | 36 | 485 | 217 |

| JPP20 | 20 | 50 | 150 | 350 | 49 | 375 | 98 |

| JPP20 | 20 | 50 | 200 | 300 | 36 | 385 | 173 |

| JPP24 | 24 | 60 | 150 | 267 | 41 | 285 | 117 |

| JPP28 | 28 | 70 | 120 | 237 | 44 | 215 | 87 |

| JPP30 | 30 | 76 | 120 | 213 | 41 | 225 | 94 |

| JPP32 | 32 | 80 | 100 | 213 | 46 | 165 | 69 |

| JPP36 | 36 | 90 | 100 | 178 | 41 | 178 | 78 |

| JPP40 | 40 | 100 | 100 | 150 | 36 | 190 | 87 |

| JPP43 | 43 | 110 | 80 | 152 | 43 | 135 | 60 |

| JPP48 | 48 | 120 | 80 | 130 | 38 | 145 | 62 |

| JPP56 | 56 | 140 | 60 | 120 | 44 | 85 | 44 |

| JPP59 | 59 | 150 | 60 | 110 | 42 | 98 | 46 |

| JPP64 | 64 | 160 | 60 | 100 | 37 | 105 | 50 |

| JPP72 | 72 | 180 | 50 | 90 | 41 | 82 | 39 |

| JPP80 | 80 | 200 | 50 | 75 | 36 | 90 | 43 |

| JPP100 | 100 | 250 | 42 | 60 | 36 | 65 | 35 |

| JPP120 | 120 | 305 | 30 | 55 | 42 | 52 | 20 |

| JPP120 | 120 | 305 | 35 | 45 | 29 | 60 | 28 |

| JPP120 | 120 | 305 | 38 | 42 | 25 | 67 | 35 |

| JPP120 | 120 | 305 | 42 | 42 | 25 | 75 | 42 |

| JPP130 | 130 | 330 | 30 | 47 | 37 | 55 | 22 |

| JPP130 | 130 | 330 | 35 | 42 | 30 | 62 | 30 |

| JPP130 | 130 | 330 | 38 | 40 | 26 | 74 | 36 |

| JPP140 | 140 | 355 | 30 | 38 | 28 | 53 | 25 |

| JPP140 | 140 | 355 | 35 | 37 | 26 | 65 | 33 |

| JPP140 | 140 | 355 | 38 | 32 | 20 | 68 | 36 |

| JPP145 | 145 | 368 | 38 | 30 | 19 | 64 | 40 |

| JPP150 | 150 | 380 | 30 | 34 | 26 | 50 | 26 |

| JPP150 | 150 | 380 | 38 | 31 | 21 | 68 | 40 |

| JPP165 | 165 | 420 | 30 | 30 | 25 | 59 | 28 |

| JPP165 | 165 | 420 | 38 | 25 | 15 | 75 | 42 |

| JPP180 | 180 | 460 | 30 | 25 | 21 | 60 | 31 |

| JPP200 | 200 | 508 | 30 | 20 | 16 | 65 | 34 |

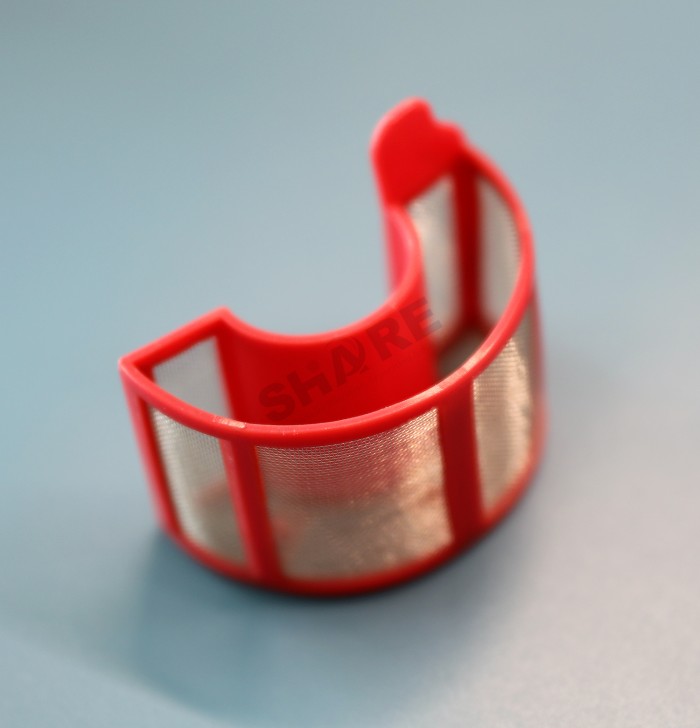

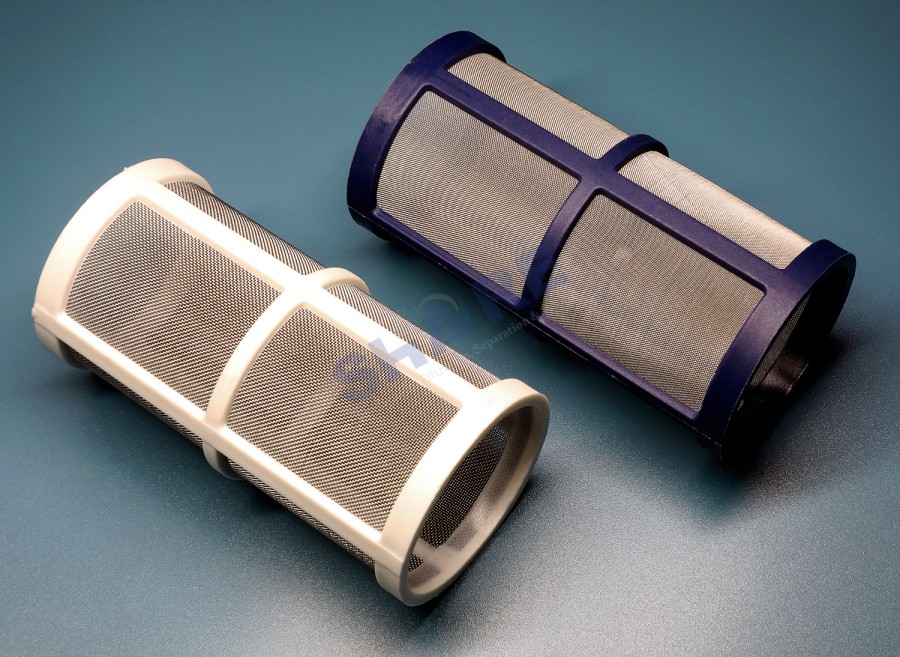

| What Share Filters Do Share Filters specializes in helping our customers design and manufacture high quality mesh filter components to around the world. As a supplier combining the woven filter mesh manufacturing and filter mesh processing according to custom-made design, we are flexible enough to adapt to our customers’ production and delivery needs. Our advanced manufacturing processes and scientific machines allow us to create filter components in any shape or configuration – from simple, traditional components like filter mesh piecess and filter bags to highly complex elements like mesh insert injection moulding plastic filters. |

Factory Capabilities

|  |  |

| Share Filter synthetic meshes can be made from a variety of materials such as polyamide, polyester, polypropylene, etc. You can order by the roll or cut shape. | Slitting is also used for manufacturing mesh strips and produces a closed edge with very little material build up at the edge. | Our cutting method include Laser cutting, Cold cutting, Heatt cutting, Stamping. Professional cutting using custom made tools that will not damage the materials. |

|  |  |

| Sonic welding are accurate, clean. Precision sleeves and bags for blood filtration, rosin bag for rosin press are examples of applications that benefit from this technology. | Share Filters sewing products are carried out by highly skilled and experienced machinists, which ensure you get the right level of consistent quality. | Custom plastic molded filter combine precise filter mesh with polymer plastic. Industry serve: Automotive, Appliances, Food and beverage, Medical, Life Science and Laboratory. |

Share Filters Workshops

Application of Share Filters Products

|  |  |  |  |

| Fuel filter | Biopsy bag | Dispenser filter | Coffee filter | Drip irrigation filter |

| Automotive | Healthcare | Appliance | Food & Beverage | Agriculture |

Contact Us

Please connect with us so we can learn more about your application and design specifications!