Share Group Limited |

|

Verified Suppliers

|

|

| Fiber Chemical Resistance Comparison | ||||||||

| Fiber Type | Continuous Working Temp. | Max. Working Temp. | Filtration Characteristic | Abrasion Resistance | Hydrolysis Resistance | Acid Resistance | Alkalis Resistance | Oxidation Resistance |

| Nylon(PA) | 110ºC | 115ºC | Moderate | Excellent | Poor | Moderate | Good | Moderate |

| Polyester(PET) | 135ºC | 150ºC | Excellent | Excellent | Poor | Moderate | Poor | Good |

| Polypropylene(PP) | 90ºC | 100ºC | Good | Good | Excellent | Excellent | Excellent | Poor |

| Item Name | Woven PP Mesh Filter Tubes |

| Factory | Taizhou Share Filters Co., Ltd. |

| Brand | SHARE FILTERS |

| Material | Our precision filter mesh in polypropylene(PP). Nylon(PA), polyester(PET), polyethylene(PE) are available. |

| Tube diameter | Down to 1cm |

| Tube length | Customizable |

| Shape | Tubes, rectangles |

| Specification | Customizable |

| Processing technologies | Cold, heat, laser and ultrasonics welding |

| Welding types | 1) Overlapping Welding (Jointed Surface) High welding strength The productivity is low and small-sized parts can't be welded. 2) Corner or Edge Welding (Jointed Edge) Low welding strength The productivity is high and even small-sized parts can be welded. |

| Seam types | 1) Single seam

3) Overlapping seam

|

| Micron ratings | 75um to 3360um |

| Open area | 16% to 60% |

| Thickness | 100um to 1800um |

| Features | 1. Mesh filter tube made of food grade polypropylerne material. 2. With a precise mesh design, even the smallest particles can be effectively captured. 3. With superior filtration performance, your filter remains free of impurities and contaminants. 4 Available in a wide range of micron ratings, opening area, thread diameters and thickness. 5. Can be further processed into various types of custom plastic molded filters. |

| Advantages | 1. Any size or shapes 2. Non-fraying edges 3. Many materials selection(PA, PET, PP, PE) 4. Safe for food and healthcare 5. Quick delivery |

| Quality Control | Visual inspection, optical or pressure sensitive equipment and automated 3D image-inspection equipment |

| Applications | Mesh tubes can be molded to plastic filters by SHARE and widely used and applied in industries, such as automotive, irrigation, chemical processing, home appliance, food and beverage, medical and health, aerospace, electronics. |

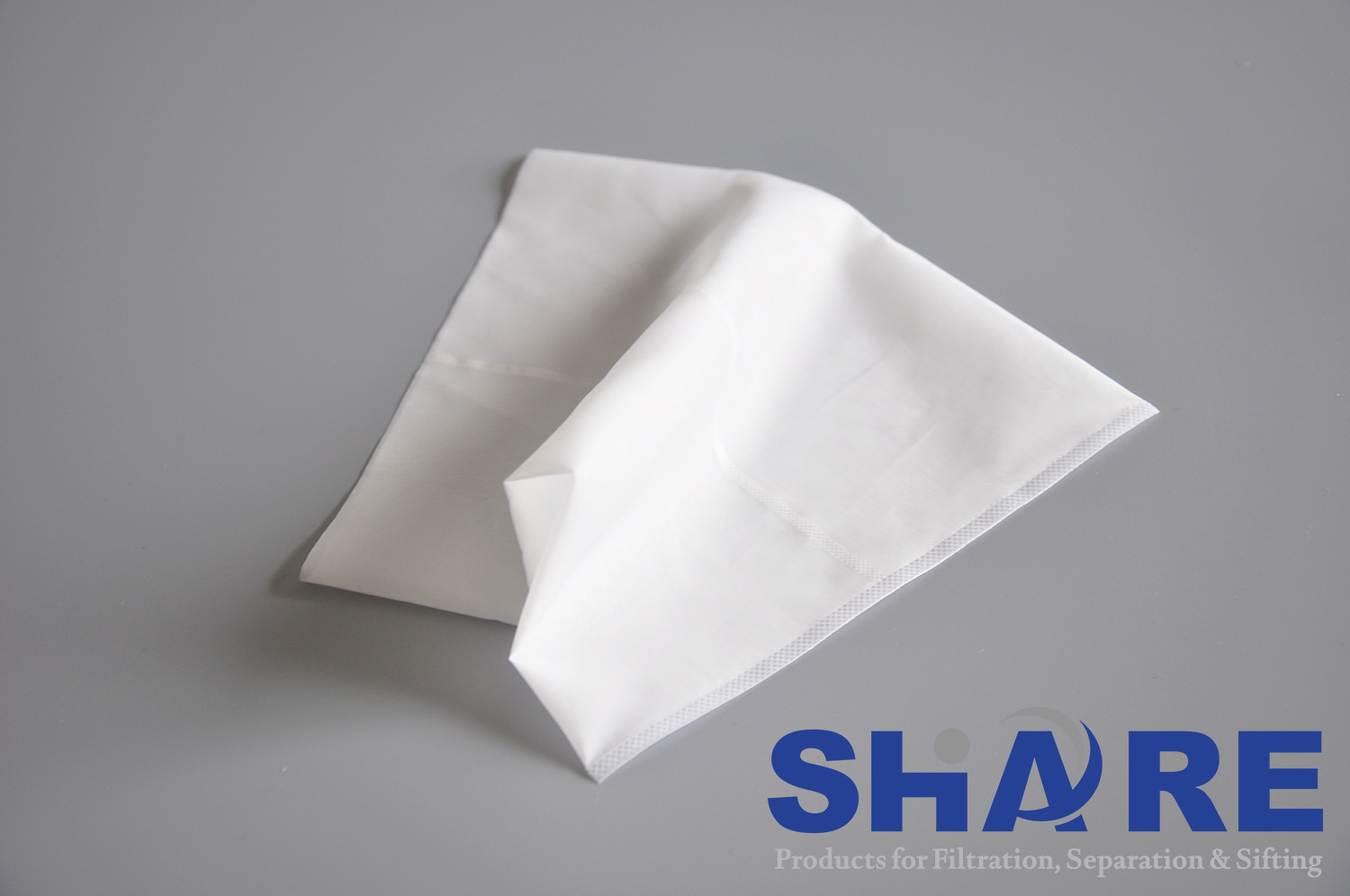

Here are a few typical images of SHARE PP mesh filter tubes. Please contact us for more information.

Tube cut to length and cut to size.

Fabric tubes and rectangles with two open ends.

Ultrasonic sealing for one end if needed.

Suitable for molded cylindrical filters.

Production technology: cold, heat, ultrasonics and laser depending

on your required edge quality.

Above are just a few examples that SHARE processes with cold cutting, laser slitting, ultrasonics welding and hot cutting technology. Contact us with your requirements and we are happy to advise the best fabrication technology according to your specification, drawing or application.

SHARE has been customizing mesh components to fit our customers' needs and applications for more than 30 years. After years of developments, SHARE has developed expertise in almost all processing technologies, including cold cut&stamping, heat slitting, laser cutting, ultrasonics cutting, sewing, pleating, and injection molding etc. We are able to shape our precision woven filter mesh fabrics(PA, PET, PP) into various cut-to-order discs, tubes, ribbons, shapes, cut-to-size sections, bags and molded filters.

1. Where is your factory located? How can I visit there?

We are in Taizhou city, Zhejiang province China. By train, we are

one hour away from Hangzhou and two hours away from Shanghai.

2. Can I get free samples and how long can you deliver them?

We are pleased to provide you with free samples for your

evaluation, which will be sent to you within 2 days. Please feel free to reach out to us for samples.

3. How long does a quotation take?

In most cases, we respond within 2 days. If something in RFQ need be confirmed, we will promptly

notify you soon.

4. How quickly can I get my order finished?

The production lead time is dependent on the quantity. Typically,

it takes 5 to 15 working days for us to complete mass production once you have

placed the order.

5. What about your quality control?

By visual inspection, optical or pressure sensitive equipment and

automated 3D image-inspection equipment, our production operators

conduct self-inspections at every stage of the process.

Additionally, we have spot inspections and final inspections

carried out by our Quality Control (QC) team.

6. What's your largest advantage?

One of our core competencies is our excellent converting

capabilities from yarn over weaving to converted items with

professional technical team and quality guarantee and management

for more than 30 years.

7. What kind of payment terms do you accept?

T/T and LC and more.