Share Group Limited |

|

Verified Suppliers

|

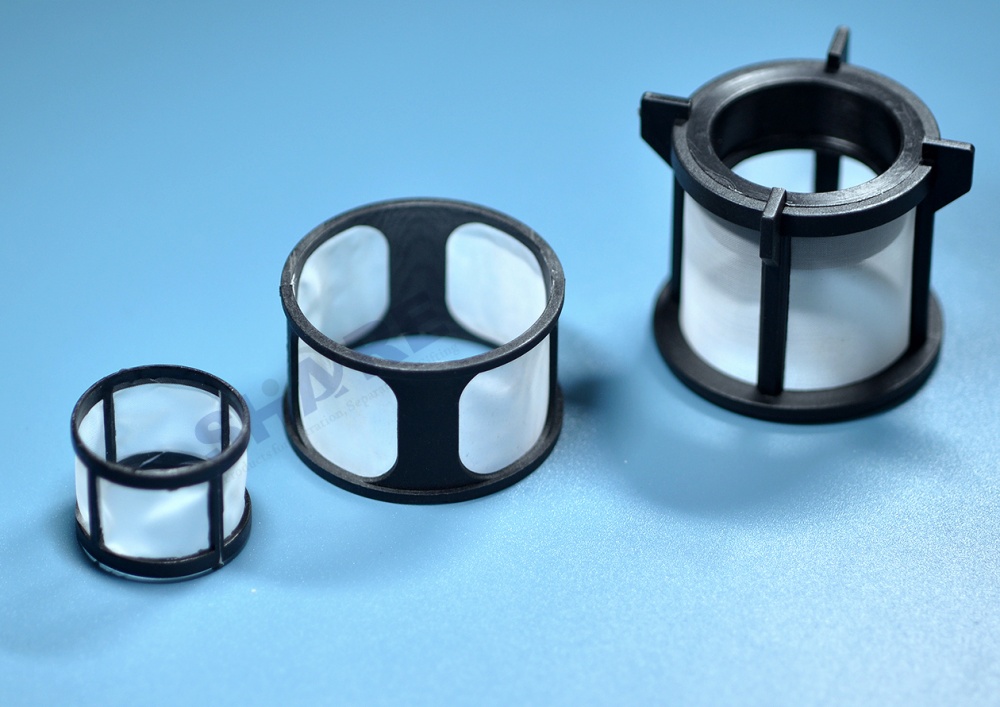

Diesel Funnel Filter For Truck Dynamotor Oil Tank Refueling Opening Port

Funnels with built-in filters are commonly used for gasoline or other fluids. This Filter consists of a synthetic filter mesh held in a polymer plastic frame, allowing for a more robust part/product giving more reliability and longevity in its use.

By using a diesel funnel filter designed for oil tank refueling can help minimize the risk of contaminants entering your truck's oil tank and ensure cleaner fuel is introduced into the system. When refueling truck, pour the diesel fuel through the funnel with the filter attached. The filter will catch any impurities or debris, preventing them from entering the oil tank. Proceed with slow and steady pouring to allow the fuel to pass through the filter effectively.

The Features of Diesel Funnel Filter:

High Filtration Efficiency: this filter are designed to effectively trap and remove contaminants and debris from the fuel to prevent clogging of the main filtration system of oil tank.

Durability: Share Filters' diesel funnel filters are typically made from high-quality materials that are resistant to wear and brushing, ensuring long-term reliable performance.

Easy installation: The moulded filters are designed to be easy to install and replace, with simple mounting and connection features that make it easy for perform maintenance.

Other Custom-tailored Fuel Filters

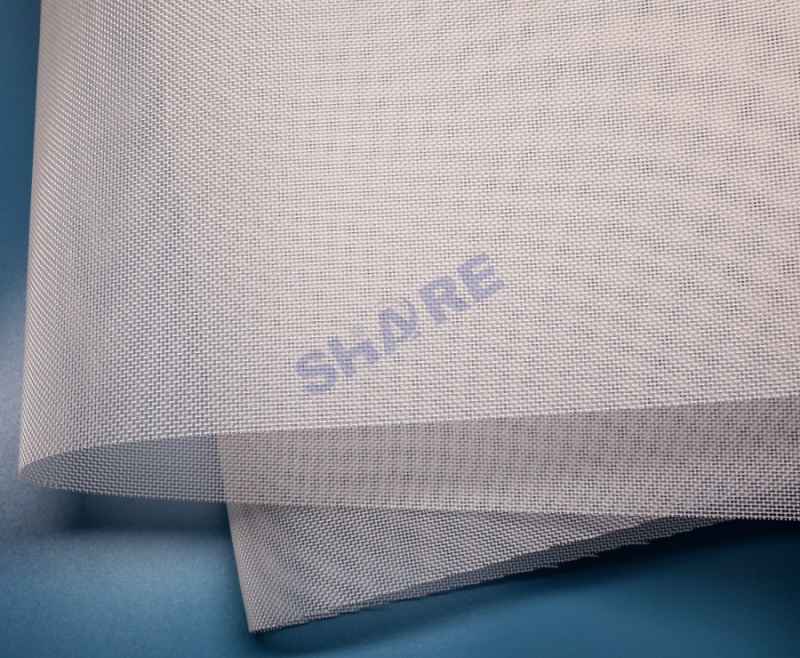

Share Filtes Materials Options

| Support rim material | PA6, PA66, PET, PP, ABS, POM, and other High-Performance Thermoplastics |

| Filter media | Nylon mesh, polyester mesh, PP mesh, stainless steel mesh, brass mesh | |

| Micron rating | 16μm - 1500μm | |

| Mesh parts fabrication | Laser cutting, sonic cutting, sonic welding | |

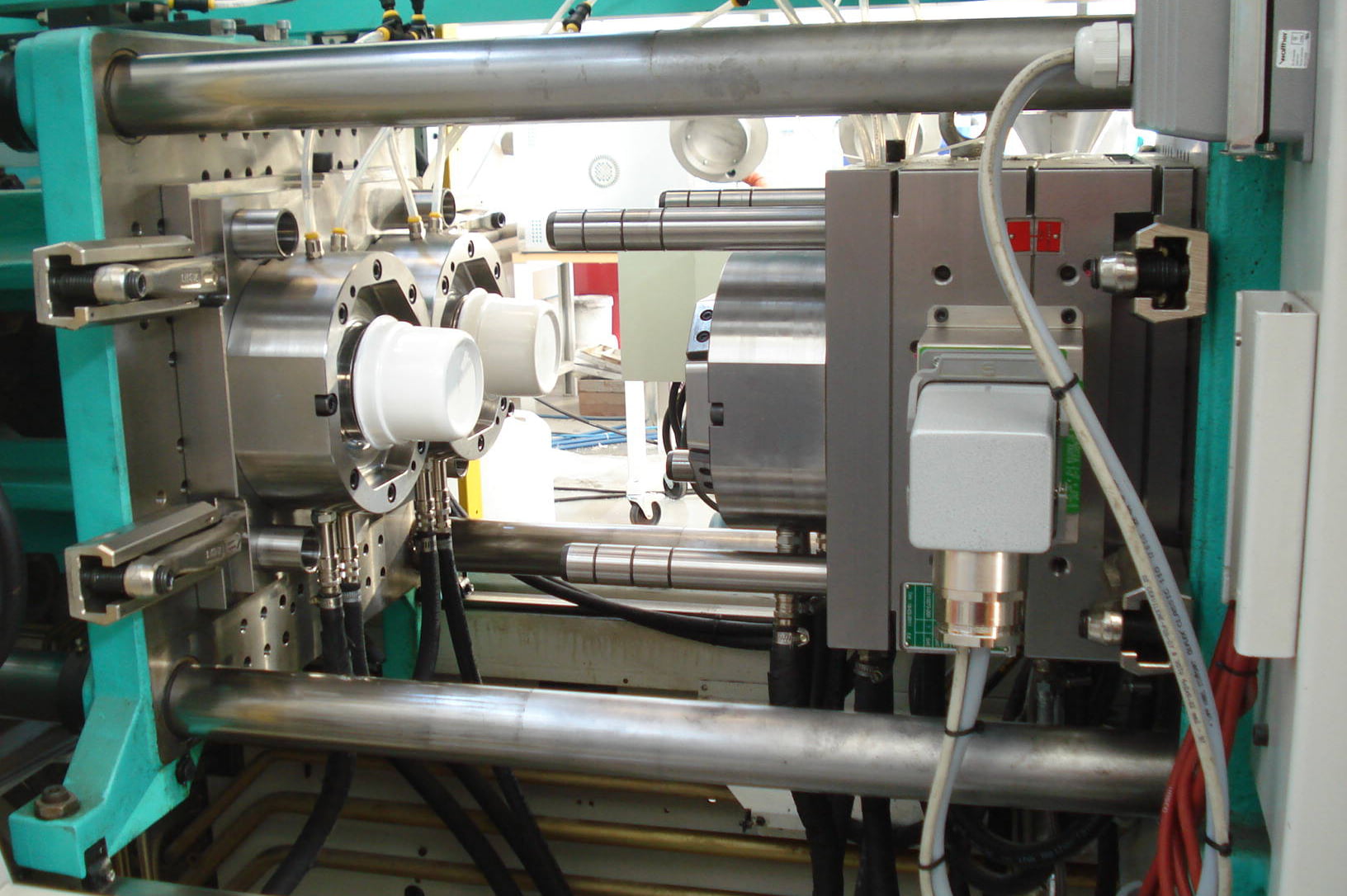

| Process method | Mesh insert injection moulding | |

| Specification | Custom | |

| Colour | Custom |

Properties of Polymer Plastic for Rim

PA6 (polyamide 6)

Tough, abrasion-resistant, good

vibration damping, resistant to solvents, fuels and lubricant

PA66 (polyamide6.6)

Rigid, stiff, abrasion-resistant, dimensionally stable

at heat exposure.

PET (polyethyleneterehthalate) High rigidity, high hardness, high

chemical resistance, good dimensional stability.

PP (polypropylene)

Good chemical resistance, more heat resistant

than PVC

PEEK (polyetheretherketone) High mechanical strength,

stiffness, toughness, temperature, chemical and radiation

resistance

How To Select the Right Filter Mesh for Plastic Filter?

You Can Follow These Points.

|

|

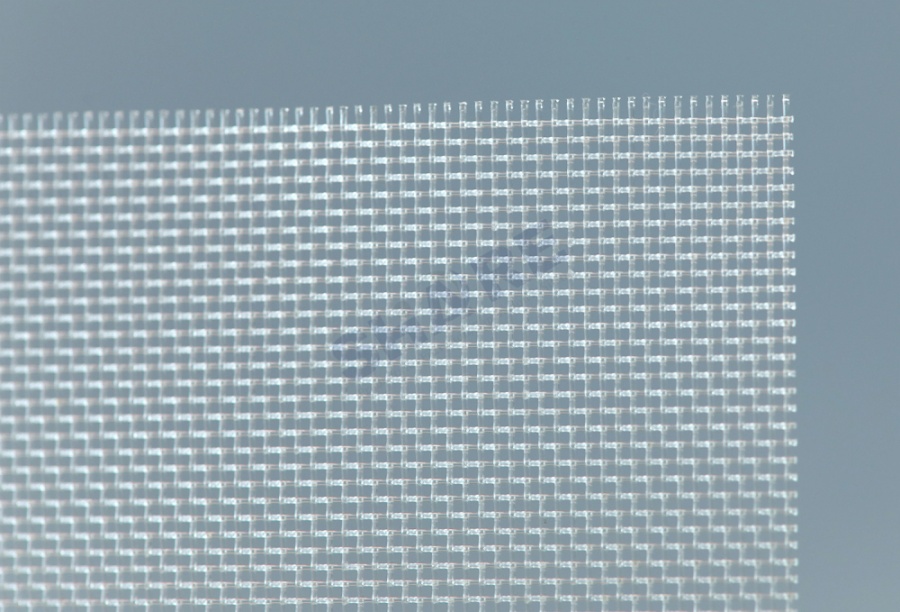

Nylon Filter Mesh Data Sheet

| Ref. No. | Mesh Count | Thread Diam. | Mesh Opening | Opening Area | |

| mesh/cm | mesh/inch | µm | µm | % | |

| JPP5 | 5 | 12 | 500 | 1500 | 56 |

| JPP6 | 6 | 16 | 400 | 1267 | 58 |

| JPP7 | 7 | 18 | 350 | 1079 | 57 |

| JPP8 | 8 | 20 | 350 | 900 | 52 |

| JPP9 | 9 | 24 | 250 | 860 | 60 |

| JPP10 | 10 | 25 | 300 | 700 | 49 |

| JPP12 | 12 | 30 | 250 | 583 | 49 |

| JPP12 | 12 | 30 | 300 | 533 | 41 |

| JPP14 | 14 | 35 | 300 | 414 | 34 |

| JPP16 | 16 | 40 | 200 | 425 | 46 |

| JPP16 | 16 | 40 | 250 | 375 | 36 |

| JPP20 | 20 | 50 | 150 | 350 | 49 |

| JPP20 | 20 | 50 | 200 | 300 | 36 |

| JPP24 | 24 | 60 | 150 | 267 | 41 |

| JPP28 | 28 | 70 | 120 | 237 | 44 |

| JPP30 | 30 | 76 | 120 | 213 | 41 |

| JPP32 | 32 | 80 | 100 | 213 | 46 |

| JPP36 | 36 | 90 | 100 | 178 | 41 |

| JPP40 | 40 | 100 | 100 | 150 | 36 |

| JPP43 | 43 | 110 | 80 | 152 | 43 |

| JPP48 | 48 | 120 | 80 | 130 | 38 |

| JPP56 | 56 | 140 | 60 | 120 | 44 |

| JPP59 | 59 | 150 | 60 | 110 | 42 |

| JPP64 | 64 | 160 | 60 | 100 | 37 |

| JPP72 | 72 | 180 | 50 | 90 | 41 |

| JPP80 | 80 | 200 | 50 | 75 | 36 |

| JPP100 | 100 | 250 | 40 | 60 | 36 |

| JPP120 | 120 | 305 | 40 | 43 | 25 |

| JPP130 | 130 | 330 | 40 | 37 | 23 |

| JPP140 | 140 | 355 | 30 | 38 | 33.7 |

| JPP150 | 150 | 381 | 30 | 34 | 30.25 |

| JPP165 | 165 | 420 | 30 | 28 | 20.7 |

| JPP180 | 180 | 460 | 30 | 25 | 19.5 |

| JPP200 | 200 | 510 | 30 | 16 | 10.2 |

This data sheet just include our common specification,

please contact us if you have other custom specification

Why Choose Share Filters ?

Selecting the right filter media and opening aperture for separation, purification, filtration, screening and sieving is a vital processing stage and the key to success. Share Filters' customer base comes from a wide variety of industries including Automotive, Chemicals, Home appliances, Food and beverage, Milling, Medical, Life Science and laboratory, as well as Electronical, giving us a wealth of filtration experience in many areas.

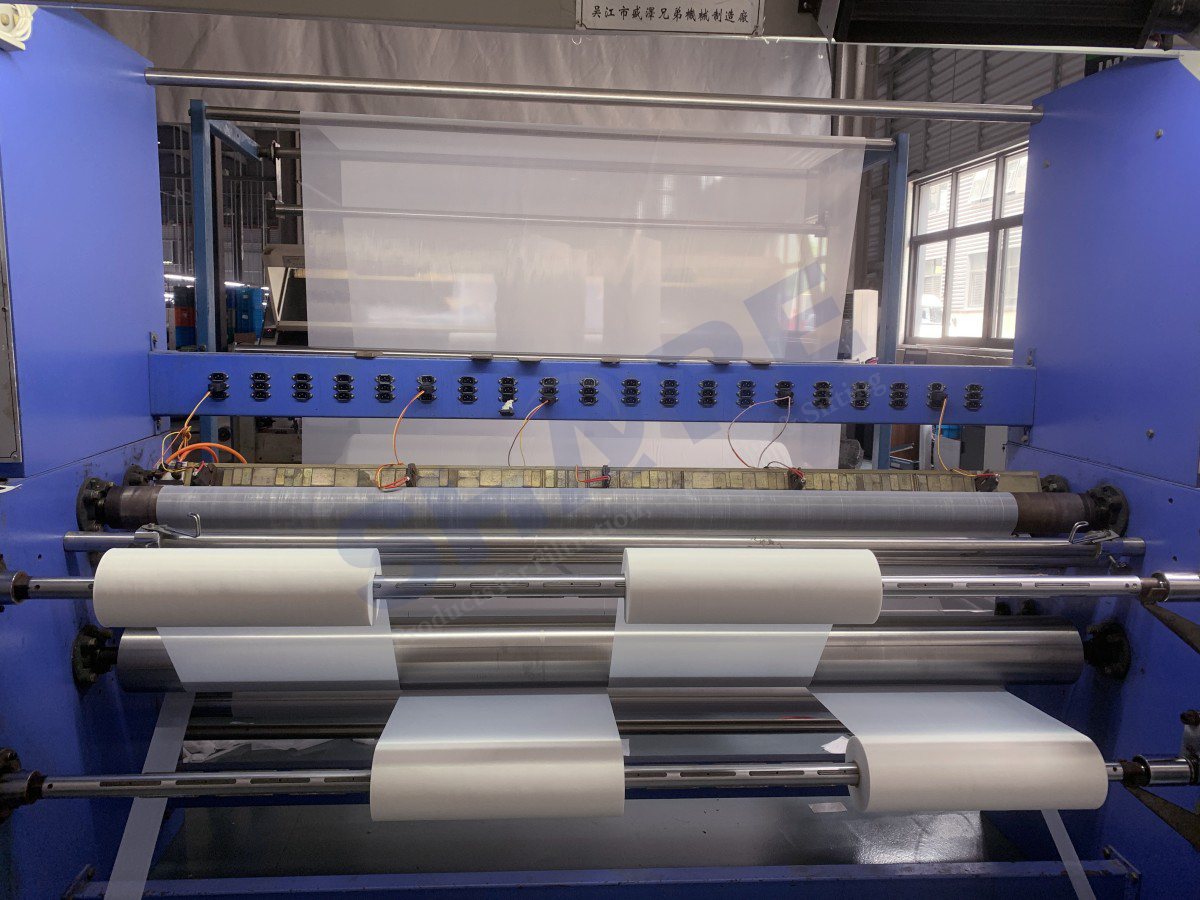

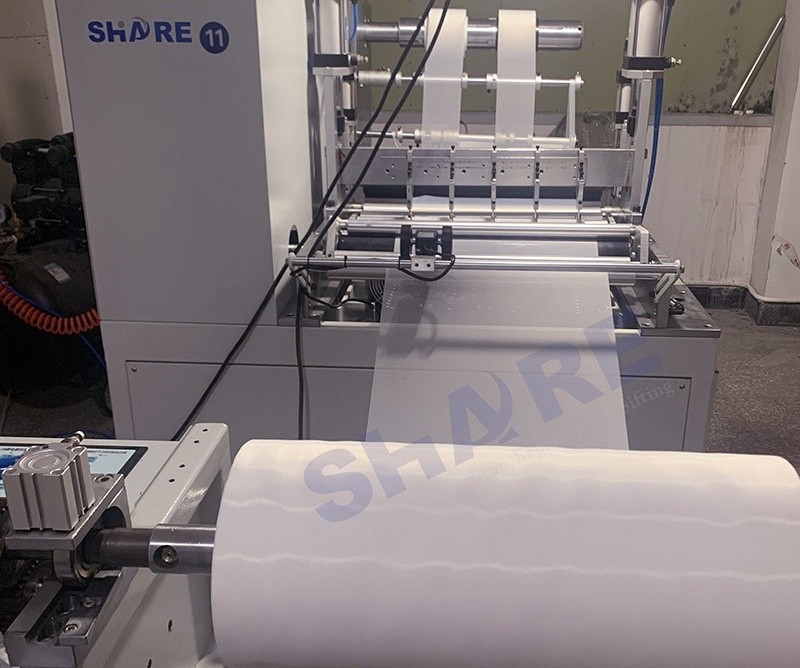

Share Filters Workshops

Share Filters Products Applications

|  |  |  |  |  |

| Automotive | Appliance | Medical | Food & Beverage | Chemical | Environmental |

Contact us

Please connect with us so we can learn more about your application

and design specifications!