Share Group Limited |

|

Verified Suppliers

|

|

120 Micron Nylon Filter Mesh For Grape Wine Filtration Food Grade Fabric

Share Filters' fine nylon filter mesh is made from strong PA6 yarn, it is ideal for pulping grapes and straining off the seeds and stems. It is abrasion resistance and it’s material will not be torn or absorb too much juice. Made of synthetic yarn means that it dries faster. It's safe for food contact as the nylon is food grade. The abrasion resistance make It is reusable.

Nylon Mesh Construction

|

Mesh count (n/cm), (n/in) The mesh count stands for the number of openings per inch.

Mesh opening (w), (μm) The mesh opening w is the distance between two adjacent warp or weft thread.

Thread diameter (d),( μm) The thread diameter is measured on the thread before weaving.

Open area (%) The percentage of the open are is the sum of all mesh openings as percentage of the total fabric area |

Nylon Filter Mesh Specification Options

| Yarn | Monofilament (Single Filament), Multi-filament |

| Yarn Diameter | From 30 micron to 600 micron |

| Mesh Opening | From 3 micron to 2000 micron |

| Open Area | From 10% to 60% |

| Weave Type | Plain Weave, Twill Weave and Satin Weave |

| Treatment | Washing, Heat-setting, Calendaring, Water-repellent |

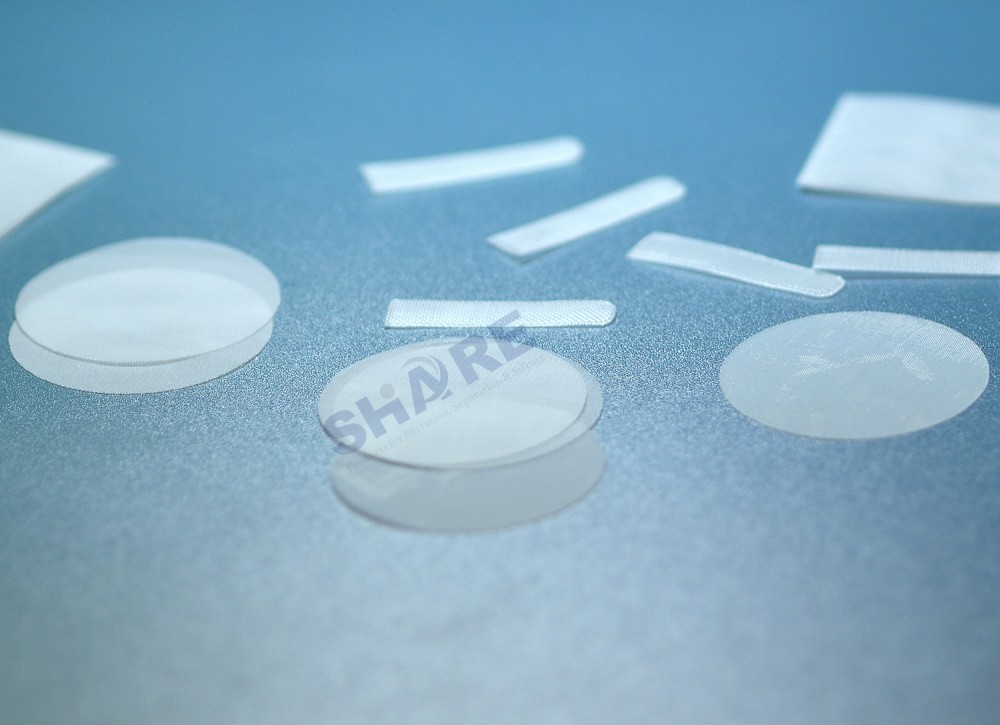

| Size | Can slit or cut in custom dimension |

| Colour | White, or customize |

| High tensile strength Precise and even mesh opening Food grade Elasticity and flexibility Good resistance to alkalis Temperatures up to 100°C

Hydrophilic Soft, smooth feeling Easy cutting, dyeing, and cleaning |

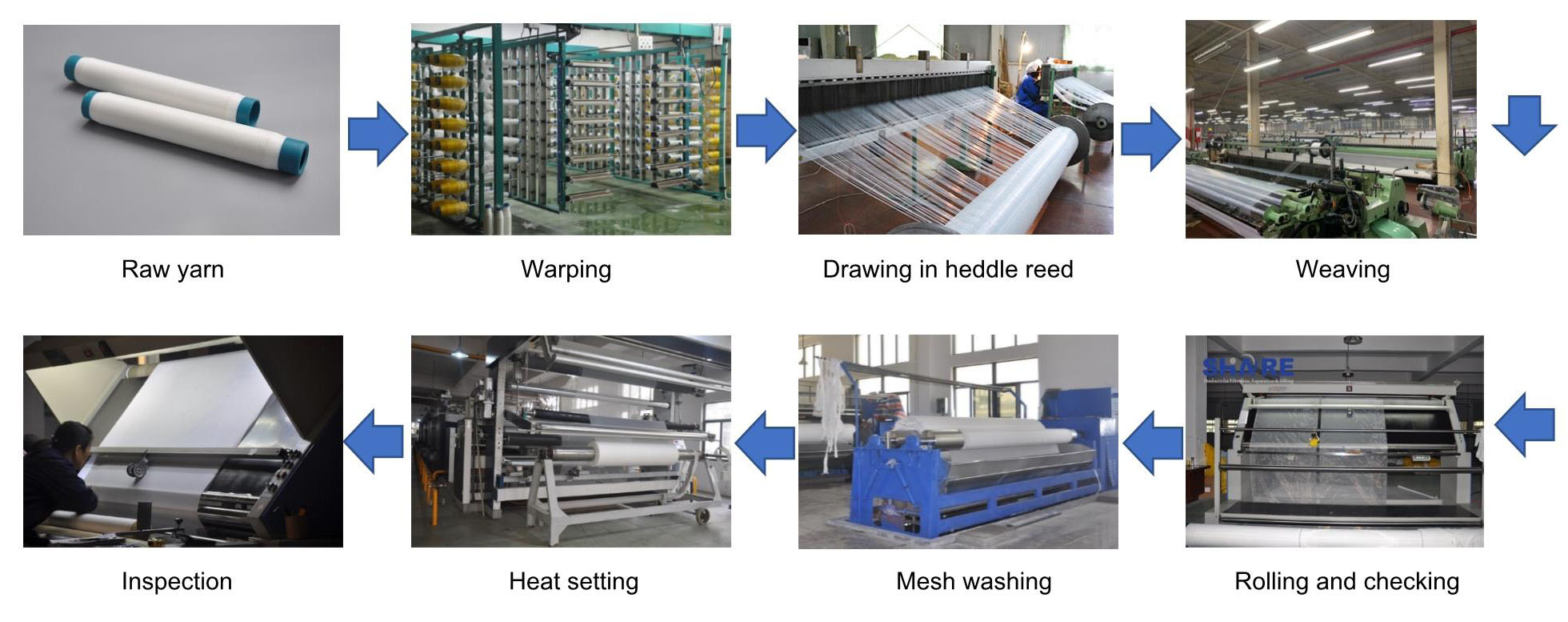

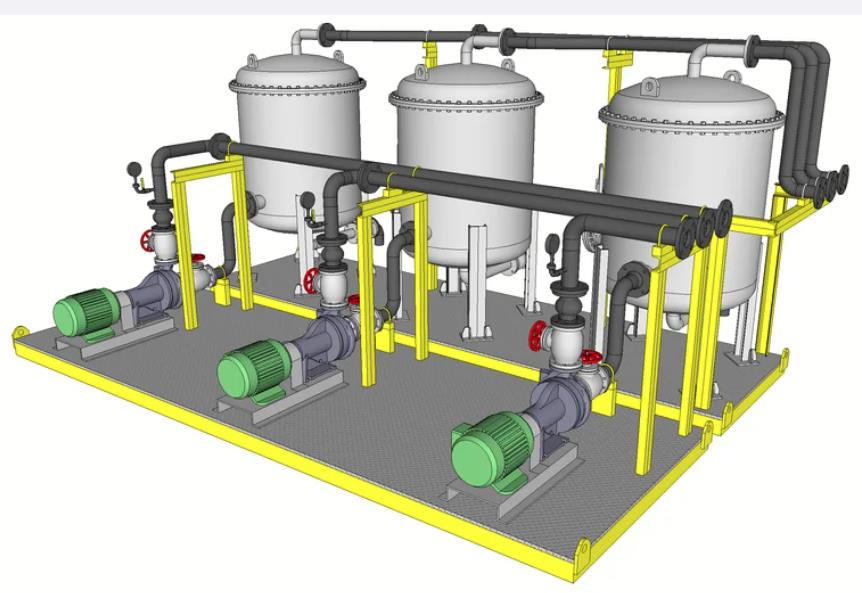

Factory Capabilities

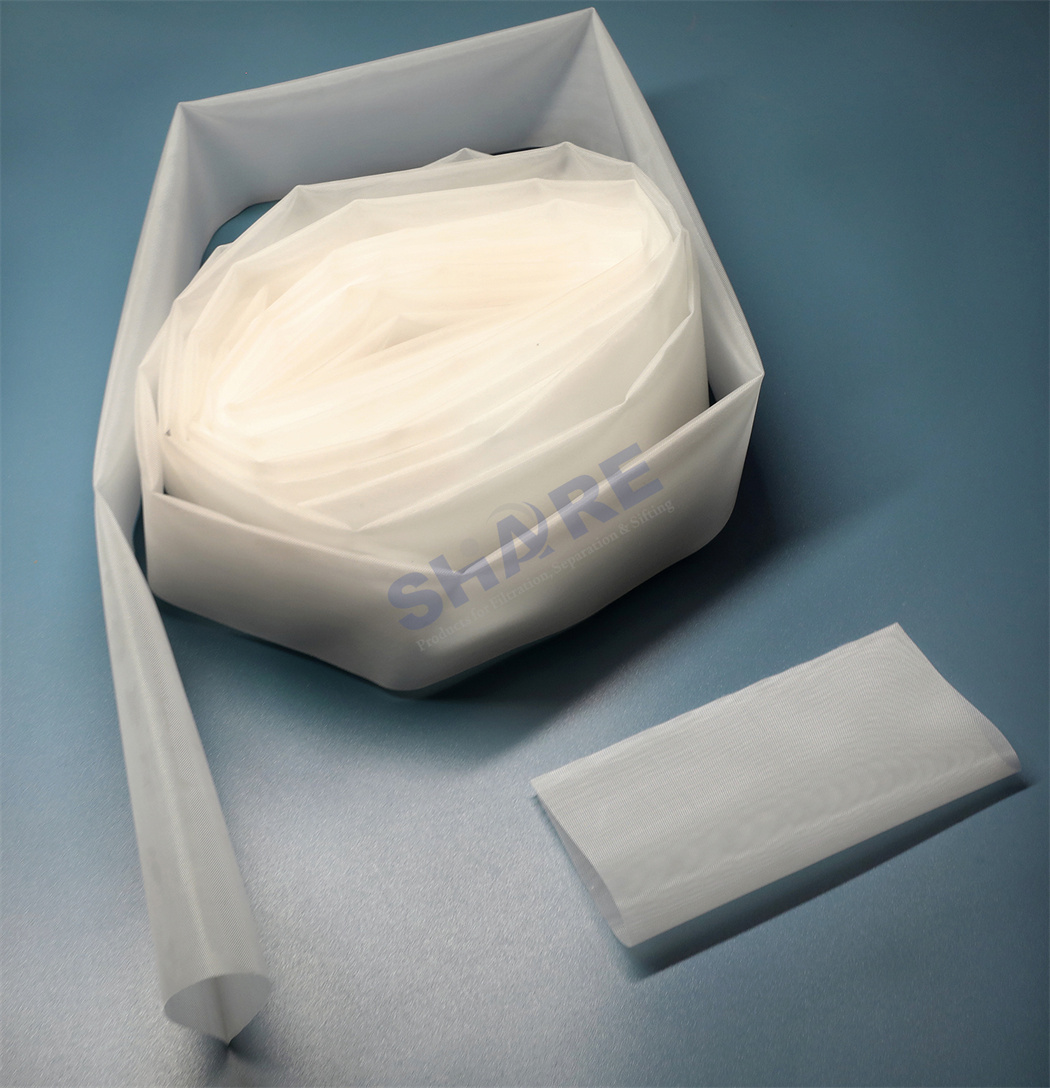

We're a trusted manufacturer of precision filter mesh, filter mesh components and mesh insert injection-molded

filters. There are many ways to make a filtration product. Share Filter can offer the filter mesh in different

materials including nylon mesh, polyester mesh, pp mesh, metallic mesh, and we can convert the filter

mesh to filter mesh ribbons, filter mesh tubes, filter mesh bags and mesh insert plastic molded filters

to meet customs' wine Filtration demands.

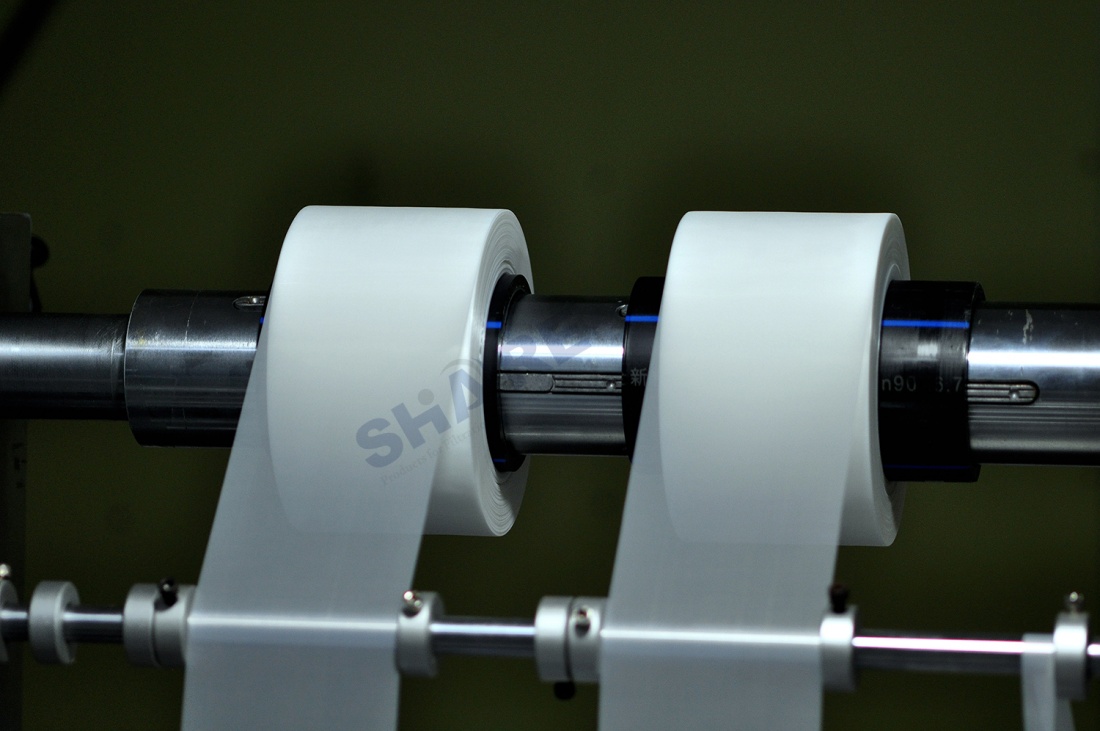

Filter Mesh in Rolls

The width of nylon filter mesh rolls can be in 100cm, 127cm, 150cm, 160cm, 175cm, 183cm, 365cm or

other custom width.

Length can be 30m, 50m, 70m, or other custom length.

Filter Mesh in Narrow Strips

About Us

Share has over 20 years of experience developing and manufacturing filter mesh and custom product solutions

for our customer's screen and filtration needs. We can offer the filter mesh and filter components services including

slitting, cutting, welding, sewing and injection molding. Our customer base comes from a wide variety of industries

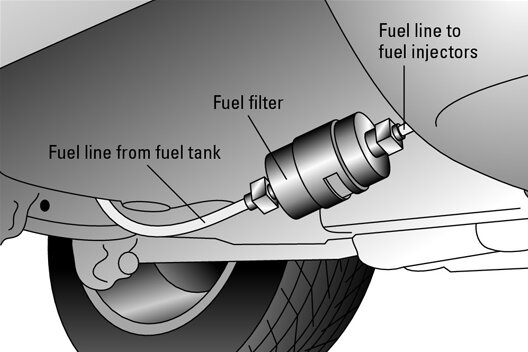

including – Automotive, Home appliances, Food and beverage, Milling, Medical, Life Science and laboratory,

Electronical as well as more general engineering, giving us a wealth of experience in many areas.

Share Filters Products Application

|  |  |  |  |  |

| Automotive | Healthcare | Appliance | Food & Beverage | Environment | Chemical |