Qingdao Henger Shipping Supply Co., Ltd |

|

Verified Suppliers

|

|

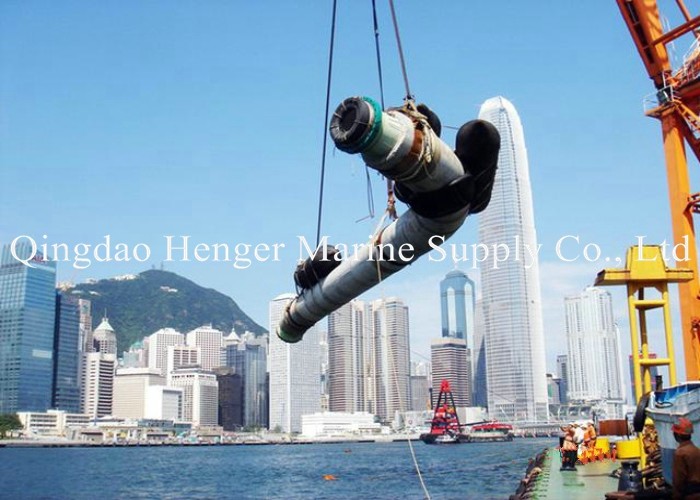

Rescue Airbag With Inflatable Airbag With Ship Launching Airbag

Application areas of airbags:

Ship launching and launching:

After more than 20 years of practice, launching ships have

developed from flat-bottomed ships weighing tens of tons to large

ships with tens of thousands of tons. Practice has proved that the

airbag launching process is safe and reliable. This technology has

been recognized by the shipbuilding industry and port construction

industry at home and abroad, and the airbag launching technology

has been promoted in the United States, Europe, Southeast Asia and

other countries.

Heavy goods handling:

Marine airbags are widely used in caisson lifting, transportation,

launching and other fields in port construction, as well as

component displacement and launching.

Floating and salvage:

Marine airbags can generate greater buoyancy and strong

load-bearing capacity, and are now widely used in rescue of

stranded ships and other buoyancy and salvage fields.

The principle of ship airbag hauling:

The working principle of the airbag "roller" hauling caisson is

basically the same as that of the drum hauling heavy objects.

Several airbags are placed between the bottom of the caisson and

the ground, and the caisson is inflated to lift the caisson, and

then the caisson is pulled by external force to roll the airbag,

thereby driving the caisson to move. Compared with the traditional

roller, the airbag can produce greater deformation under the weight

of the caisson. Increase the contact area between the airbag and

the ground, so that the pressure per unit area is reduced, the

force is even, and the adaptability to the site is strong. The

structure and characteristics of the structure The airbag is a long

cylindrical shape and consists of 3 layers of rubber and nylon cord

fabric. The inner and outer layers are rubber layers, and the

middle is a nylon cord fabric layer.

Inflatable Marine Rubber Airbag Technical Parameter

| Model | D(m) | P(Mpa) | Working Height(m) | Unit Bearing Capacity(ton/m) | |||||

| 0.4D | 0.5D | 0.6D | 0.4D | 0.5D | 0.6D | ||||

| S1 |

S10 | 0.8 | 0.20 | 0.32 | 0.40 | 0.48 | 15.1 | 12.6 | 10.0 |

| 1 | 0.16 | 0.40 | 0.50 | 0.60 | 15.1 | 12.6 | 10.0 | ||

| 1.2 | 0.14 | 0.48 | 0.60 | 0.72 | 15.8 | 13.2 | 10.6 | ||

| 1.5 | 0.11 | 0.60 | 0.75 | 0.90 | 15.5 | 13.0 | 10.4 | ||

S11 | 0.8 | 0.19 | 0.32 | 0.40 | 0.48 | 14.3 | 11.9 | 9.5 | |

| 1 | 0.15 | 0.40 | 0.50 | 0.60 | 14.1 | 11.8 | 9.4 | ||

| 1.2 | 0.13 | 0.48 | 0.60 | 0.72 | 14.7 | 12.2 | 9.8 | ||

| 1.5 | 0.10 | 0.60 | 0.75 | 0.90 | 14.1 | 11.8 | 9.4 | ||

S12 | 0.8 | 0.24 | 0.32 | 0.40 | 0.48 | 18.1 | 15.1 | 12.1 | |

| 1 | 0.19 | 0.40 | 0.50 | 0.60 | 17.9 | 14.9 | 11.9 | ||

| 1.2 | 0.16 | 0.48 | 0.60 | 0.72 | 18.1 | 15.1 | 12.1 | ||

| 1.5 | 0.13 | 0.60 | 0.75 | 0.90 | 18.4 | 15.3 | 12.2 | ||

| 1.8 | 0.10 | 0.72 | 0.90 | 1.08 | 17.0 | 14.1 | 11.3 | ||

| S2 |

S20 | 1 | 0.24 | 0.40 | 0.50 | 0.60 | 22.6 | 18.8 | 15.1 |

| 1.2 | 0.20 | 0.48 | 0.60 | 0.72 | 22.6 | 18.8 | 15.1 | ||

| 1.5 | 0.16 | 0.60 | 0.75 | 0.90 | 22.6 | 18.8 | 15.1 | ||

| 1.8 | 0.13 | 0.72 | 0.90 | 1.08 | 22.0 | 18.4 | 14.7 | ||

| 2 | 0.12 | 0.80 | 1.00 | 1.20 | 22.6 | 18.8 | 15.1 | ||

S21 | 1 | 0.27 | 0.40 | 0.50 | 0.60 | 25.4 | 21.2 | 17.0 | |

| 1.2 | 0.23 | 0.48 | 0.60 | 0.72 | 26.0 | 21.7 | 17.3 | ||

| 1.5 | 0.18 | 0.60 | 0.75 | 0.90 | 25.4 | 21.2 | 17.0 | ||

| 1.8 | 0.15 | 0.72 | 0.90 | 1.08 | 25.4 | 21.2 | 17.0 | ||

| 2 | 0.14 | 0.80 | 1.00 | 1.20 | 26.4 | 22.0 | 17.6 | ||

S22 | 1 | 0.31 | 0.40 | 0.50 | 0.60 | 29.2 | 24.3 | 19.5 | |

| 1.2 | 0.26 | 0.48 | 0.60 | 0.72 | 29.4 | 24..5 | 19.6 | ||

| 1.5 | 0.20 | 0.60 | 0.75 | 0.90 | 28.3 | 23.6 | 18.8 | ||

| 1.8 | 0.17 | 0.72 | 0.90 | 1.08 | 28.8 | 24.0 | 19.2 | ||

| 2 | 0.15 | 0.80 | 1.00 | 1.20 | 28.3 | 23.6 | 18.8 | ||

| 2.5 | 0.12 | 1.00 | 1.25 | 1.50 | 28.3 | 23.6 | 18.8 | ||

| S3 |

S30 | 1 | 0.35 | 0.40 | 0.50 | 0.60 | 33.0 | 27.5 | 22.0 |

| 1.2 | 0.29 | 0.48 | 0.60 | 0.72 | 32.8 | 27.3 | 21.9 | ||

| 1.5 | 0.23 | 0.60 | 0.75 | 0.90 | 32.5 | 27.1 | 21.7 | ||

| 1.8 | 0.19 | 0.72 | 0.90 | 1.08 | 32.2 | 26.8 | 21.5 | ||

| 2 | 0.17 | 0.80 | 1.00 | 1.20 | 32.0 | 26.7 | 21.4 | ||

| 2.5 | 0.14 | 1.00 | 1.25 | 1.50 | 33.0 | 27.5 | 22.0 | ||

Airbag packaging and transportation:

According to the provisions of the CB/T 3795-1996 of the People's

Republic of China Ship Industry Standard, the packaging,

transportation and storage of marine airbags should comply with the

following standards:

1. Packaging

Folded and packed with plastic woven bags.

2. Transportation

Airbags should be lifted, lifted, and rolled in an inflated state

when transported on short distances. It is strictly forbidden to

drag on the ground.

The airbag should be folded and fixed to the tray during

long-distance transportation, with a cushion underneath, and

wrapped with a wrapping film on the outside.

Technical requirements for marine airbags:

According to CB/T 3795-1996, marine airbags should meet the

technical requirements

1. Size deviation

The deviation of diameter and effective length is -2%---+2%,

The deviation of the total length is -4%---+4%

2. Elastic deformation

When using 1.2 times the working pressure as the experimental

pressure, the diameter deformation is not more than 5%

3. Safety factor

Safety factor is not less than 4.5

4. Airtightness

Inflate for 1h, the pressure drop is not more than 5%

5. Appearance requirements

Linear smooth, no cracks and bubbles, heavy skin, mixed impurities

and obvious dirt and other visual defects.

6. Safety inflation device

The safety valve should be installed on the capsule, and the trip

pressure of the safety valve should be 1.25 times of the working

pressure.

The development history of marine airbag:

According to related records, humans have been using the rolling

wood principle to carry heavy objects more than 6,000 years ago.

People still use the rolling wood principle to carry heavy objects

in daily production and life. Marine airbag is a flexible heavy

vehicle designed according to the principle of rolling wood.

In the 1980s, due to the manufacturing process and materials of

airbags, the weight of airbag launching ships was between 100 tons

and 500 tons.

In the early 1990s, people made innovations in the process and

materials of airbag manufacturing: nylon cords replaced canvas as a

new skeleton material, and a new type of integral winding

manufacturing process was developed.

Some marine airbag manufacturers still use the old production

technology of lap type. It is generally believed that the

integrally produced marine airbag is more reasonable in structure

and has a greater safety factor and bearing capacity.

Water-filled blasting test is an important method to check the

performance of marine airbags.

Service and transportation:

The product warranty period of Henger is 18 months, and the average supplier can not reach such a long time, which is

also the trust we and customers have in our factory products.

After-sales service we are online 24 hours a day, as long as you have questions we will always be there, there will

be professional staff to answer your questions and provide you with

technical support.

Transportation We can take the deflation pallet transportation and

the entire fender transportation without deflation according to the

requirements of customers. We always put the customer's

requirements first.

Thank you for reading. If you have any needs and interests, you can contact me.

Thanks for reading, if you have any interest or questions, please feel free to contact me.