BOGEN PUMPS |

|

Verified Suppliers

|

|

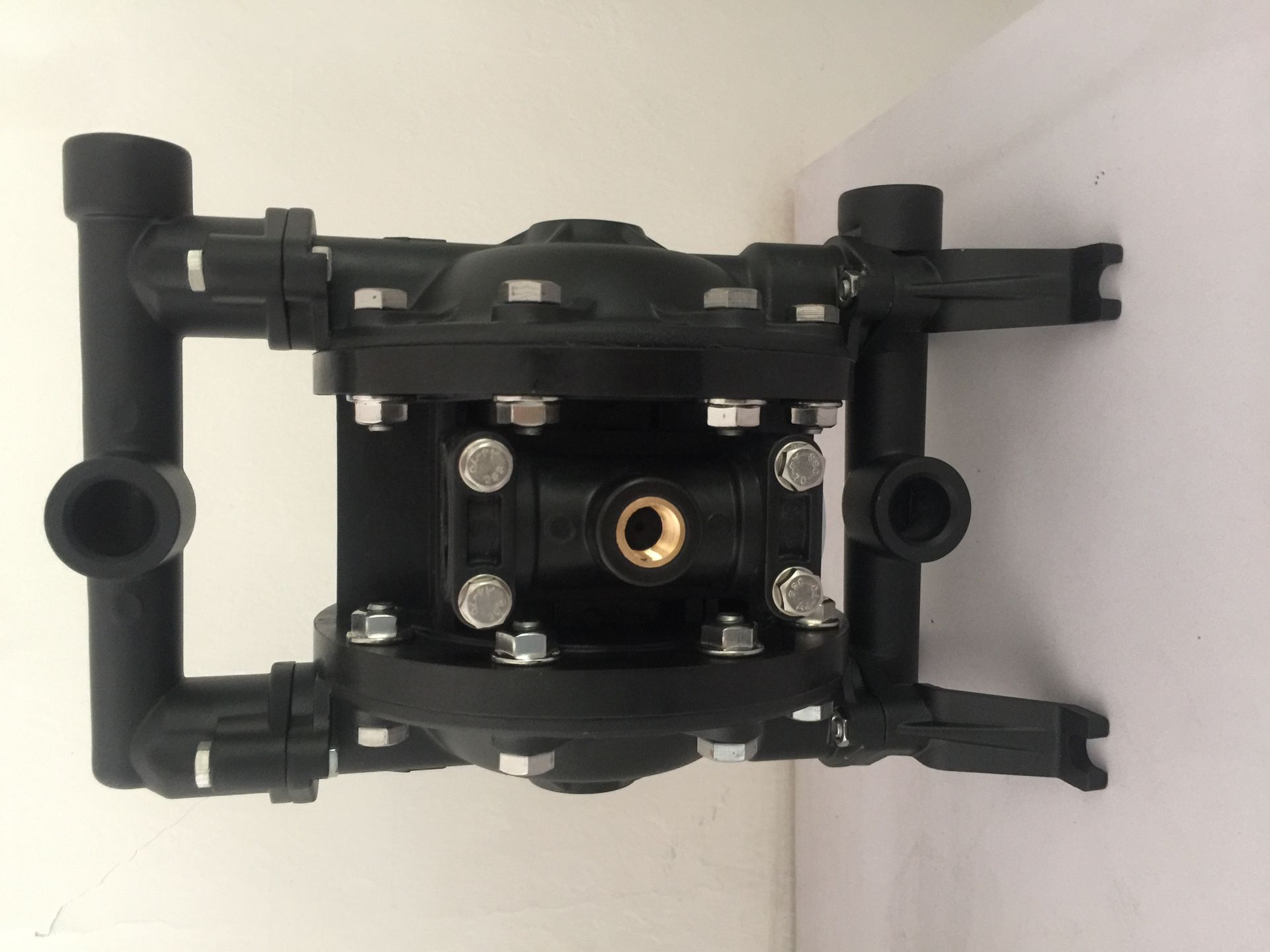

Non Leakage Sanitary Diaphragm Pump / Air 3 Inch Double Diaphragm Pump

Sanitary Diaphragm Pump Application :

·Chemical industry: acid, alkali, solvent, suspended solids,

dispersion system.

·Petrochemical industry: heavy oil, grease, mud, sludge and so on.

·Coating industry: resin, solvent, coloring agent, paint and so on.

·Chemical industry: detergent, shampoo, lotion, emulsion, hand

cream, surfactant.

·Ceramics industry: mud, porcelain pulp, lime slurry, clay pulp.

·Mining industry: coal slurry, magma, mud, mortar, lubricants and

so on.

·Water treatment: lime slurry, soft precipitates, age, chemicals,

waste water.

·Food industry: liquid semi-solid, chocolate, salt water, vinegar,

syrup, vegetable oil, soybean oil, honey.

·Beverage industry: yeast, syrup, concentrate, gas-liquid mixture,

wine, fruit juice, corn pulp and so on.

·Pharmaceutical industry: solvent, acid, alkali, plant extracts,

ointment and other pharmaceutical materials liquid.

·Paper industry: adhesives, resins, paints, inks, pigments,

hydrogen peroxide and so on.

·Electronic industry: solvent, plating solution, cleaning solution,

nitric acid, waste acid, corrosive acid, polishing liquid.

·Textile industry: dye chemicals, resins, plastics and so on.

·Construction: cement, ceramic tile adhesive, rock pulp, ceiling

finish and so on.

·Automotive industry: polishing emulsion, oil, coolant, car primer,

oil latex, varnish, varnish additives, degreasing liquid, paint and

so on.

·Furniture industry: adhesives, varnishes, dispersions, solvents,

colorants, white wood glue, epoxy resin, starch binder.

·Metallurgy, casting and dyeing industry: metal pulp, hydroxide and

carbonized pulp, dust, detergent and so on.

Sanitary Diaphragm Pump Parameters

| Item | Description | Unit | Reference Figure |

| 1 | Maximum air inlet pressure | Mpa | 0.83 |

| 2 | Maximum flow rate | L/Min | 903 |

| 3 | Maximum lift | M | 70 |

| 4 | Maximum outlet pressure | Mpa | 0.83 |

| 5 | Maximum particle size | mm | 9 |

| 6 | Weight | kg | 103 |

| 7 | Noise level | db | <70 |

A 50 X X - X X X - X (model selection)

Form of pipe mouth:A-BSP B-NPT(F) C-Flange

Diaphragm material:9 – Santoprene H – Hytrel T - PTFE/Santoprene

Ball material:9 -Santoprene H – Hytre T – PTFE A - Acetal

Ball seat material:P/K –Polypropylene/Kynoar SS –Stainless Steel

Pump material: SS –Stainless Steel AL –Aluminum Alloy CI- Carbon Steel P/K –Polypropylene/Kynoar

Maximum Applied Temperature Limits (diaphragm / ball / seal material)

Acetal ··············································· 40°- 150°F (4.4- 65.5°C)

Santoprene··········································-40°- 225°F (-40°- 107.2°C) ················································ ·40°- 220°F (4.4°- 104°C) Nitrile·················································10°- 180°F (-12°- 82°C) Viton···················································-40°- 350°F (-40°-176.6°C) Hytrel··················································-20°-150°F (-12°- 93°C) Kynar···················································10°-200°F (-28.9°- 65.5°C) Polypropylene·········································32°- 175°F (0-79.4°C)

Sanitary Diaphragm Pump Maintenance