YIKANG AUTOMATION |

|

Verified Suppliers

|

|

Ordering Code: K5004 (Nitrile), K5000 (fluororubber)

Fit for: CA-50T,RCA-50T, CA-62T,RCA-62T

Description:

1. The diaphragm repair kits is for pulse jet valves CA-50T,RCA-50T, CA-62T,RCA-62T

2. Material: NBR/fluororubber

3. This repair kit has large air - outlet , so the air can get throgh very smoothly.

4. We use high quality material , the collection equipment efficiency can be improved , the energy loss also can be reduced.

5. K5004(Nitrile) K5000(fluororubber) repair kit has unique geometric diaphragm design , high speed from multiple diaphragm to reach the highest peak in an instant.

6. We use high quality material , the collection equipment efficiency can be improved , the energy loss also can be reduced.

7. Its lifespan is about 1 million cycles.

Material:nitrile,FKM

Pressure:0.5-1Mpa

Size:2" and 2.5"

Temperature:-40℃ +100℃

Lifespan:1 million cycles

Warranty:1 year

Model:K5004(Nitrile),K5000(FKM)

1. First, Confirm the pulse valve in good condition and then

installed

2. Pulse valve will be installed directly the outer wall of flange

of gas manifold. The spray pipe across the gas manifold. According

to the drawing and manual, the pulse valve matching appropriate

spray pipe and installation. To avoid the valve install in the air

manifold bottom. If the pulse valve matched trachea and connector,

the connector will be used for sealing purpose only. It can not as

structural support components. It can not rely on the straight

connector fixed spray torch and package. The spray pipe and air

manifold must be fixed independent.

3. To tighten the hard nut, the maximum torque of 20 N*m.Tighten

the trachea, torsion of 20 N*m.

4. The connection control wire needs connect of every electric

control valve seat. Pay attention to the line adown to prevent rain

waterproof. Or through the joint and nylon pipe, it will connect

the pulse valve and electromagnetic assembly boxes of nylon pipe

connection.

5. To ensure that provide compressed air clean and dry. The air

manifold system provides moderate pressure and check for leaks

installation. ( it can brush on soap and water, check whether the

interface is bubble). Pressure was carried out on the air bag

inflated (pressure of the valve is around 0.03 ~ 0. 86 mpa),

recommend for air pressure 0.8 mpa maximum

6. Testing the pulse valve blowing, listening all the pilot valve

whether it is normal operation and whether the pulse blowing sound

is clear.

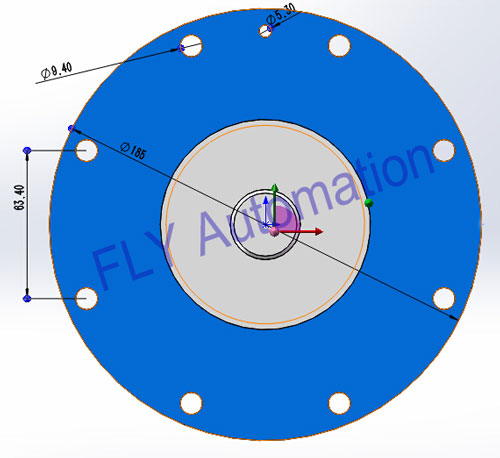

Drawings size:

1 . The design with integral compression fittings will facilitate installation because there is no need for threaded piping

2 . The high quality diaphragms are reinforced and wear resistant to guarantee a long operating life, even under harsh conditions

3 . Integral pilot operated valves satisfy all relevant EC directives

4 . The pulse diaphragm valves are especially designed for dust collector service applications, combining high flow, long life and extremely fast opening and closing to produce reliable and economical operation.

5 . The high flow, angle type bodies in combination with the special main diaphragm assemblies give the unique operating features required for dust collector service applications

Competitive Advantage:

| Our product features: | Our Services Guarantee: |

| 1) Competitive price | 1) Prompt respond (Reply with 24 hours) |

| 2) Good quality | 2) Free Samples (Customer pay for the delivery cost) |

| 3) Professional Packaging, | 3) Registration support. |

| 4) Produce according to Customers’ instruction | 4) Photos/videos are available during production. |

| 5) None delay shipment | 5) Loading inspection, and send loading photos before shipment.

|

After-sale Service

We can provide a series of after-sale service, such as product

introduction, mounting, debugging, technical support and so on.

Warranty

All item Comes with Basic 3 Month Sellers Warranty, if item

defective in 3 Month, We will offer replacement without extra

Charger(including shipping fee)After we Receive the Defective item.

If item Defective after 3 Month, Buyers can still send it back, We

will contact suppliers or Manufactory for Warranty. Buyers Might

Need to pay the Shipping fee For resend the replaced item.