QINGDAO ENNENG MOTOR CO.,LTD. |

|

Verified Suppliers

|

|

Ultra Low-Speed High Torque Direct Drive Permanent Magnet Motor

What Is The Permanent Magnet Synchronous Motor?

The Permanent Magnet Synchronous Motor (PMSM) is a type of electric motor that operates using permanent magnets embedded in its rotor. It is also sometimes referred to as a brushless AC motor or a synchronous permanent magnet motor.

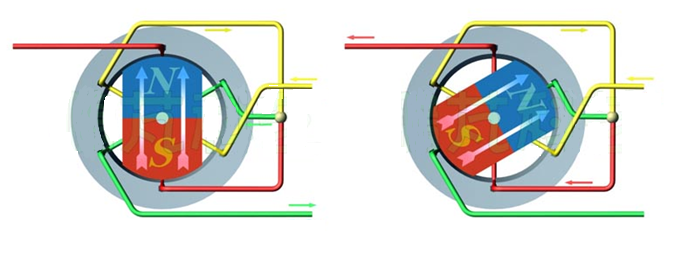

In a PMSM, the stator (the stationary part of the motor) contains a series of coils that are energized in a sequence to create a rotating magnetic field. The rotor (the rotating part of the motor) contains a series of permanent magnets that are arranged to produce a magnetic field that interacts with the magnetic field produced by the stator.

As the two magnetic fields interact, the rotor rotates, producing mechanical energy that can be used to power machinery or other devices. Because the permanent magnets in the rotor provide a strong, constant magnetic field, PMSMs are highly efficient and require less energy to operate than other types of electric motors.

PMSMs are used in a wide variety of applications, including electric vehicles, industrial machinery, and household appliances. They are known for their high efficiency, low maintenance requirements, and precise control, which makes them a popular choice for many different types of systems.

Analysis of the principle of the technical advantages of permanent magnet motor

The principle of a permanent magnet synchronous motor is as follows: In the motor's stator winding into the three-phase current, after the pass-in current, it will form a rotating magnetic field for the motor's stator winding. Because the rotor is installed with the permanent magnet, the permanent magnet's magnetic pole is fixed, according to the principle of magnetic poles of the same phase attracting different repulsion, the rotating magnetic field generated in the stator will drive the rotor to rotate, The rotation speed of the rotor is equal to the speed of the rotating pole produced in the stator.

Permanent magnet AC (PMAC) motors have a wide range of applications including:

Industrial Machinery: PMAC motors are used in a variety of industrial machinery applications, such as pumps, compressors, fans, and machine tools. They offer high efficiency, high power density, and precise control, making them ideal for these applications.

Robotics: PMAC motors are used in robotics and automation applications, where they offer high torque density, precise control, and high efficiency. They are often used in robotic arms, grippers, and other motion control systems.

HVAC Systems: PMAC motors are used in heating, ventilation, and air conditioning (HVAC) systems, where they offer high efficiency, precise control, and low noise levels. They are often used in fans and pumps in these systems.

Renewable Energy Systems: PMAC motors are used in renewable energy systems, such as wind turbines and solar trackers, where they offer high efficiency, high power density, and precise control. They are often used in the generators and tracking systems in these systems.

Medical Equipment: PMAC motors are used in medical equipment, such as MRI machines, where they offer high torque density, precise control, and low noise levels. They are often used in the motors that drive the moving parts in these machines.

Depending on how magnets are attached to the rotor and the design of the rotor, permanent magnet synchronous motors can be classified into two types:

Surface permanent magnet synchronous motor (SPMSM)

Interior permanent magnet synchronous motor (IPMSM).

SPMSM mounts all magnet pieces on the surface, and IPMSM places magnets inside the rotor.

Advantages

Small And Lightweight

In special electromagnetic and structural design, the volume-to-weight ratio is reduced by 20%, the length of the whole machine is reduced by 10%, and the full rate of stator slots is increased to 90%.

Highly Integrated

The motor and the inverter are highly integrated, avoiding the external circuit connection between the motor and the inverter, and improving the reliability of the system products.

Energy Efficient

High-performance rare-earth permanent magnet material, special stator slot, and rotor structure make this motor efficient up to IE4 standard.

Custom Design

Customized design and manufacture, dedicated to special machines, reduce redundant functions and design margins and minimize costs.

Low Vibration And Noise

The motor is directly driven, the equipment noise and vibration are small, and the impact on the construction work environment is reduced.

Maintenance Free

No high-speed gear parts, no need to change gear lubricant regularly, and truly maintenance-free equipment.

At present, because low-speed permanent magnet synchronous motors have the advantages of low speed and high torque, smaller volume than motors + reducers of the same power, stable output, high efficiency, and energy saving, they are used as driving devices in many fields, such as: mining, coal, cement, Belt conveyors, scrapers, bucket wheel machines, ball mills, hoisting machinery, open mills, internal mixers, extruders, vacuum pumps, reciprocating compressors, Low-speed pumps with low head and large flow, etc. used in the fields of metallurgy, petroleum, chemical industry, and water conservancy engineering. As we all know, mining, coal, cement, metallurgy, petroleum, chemical industry, etc. are industries with high energy consumption and high pollution. Currently, heavy machinery equipment such as belt conveyors, elevators, and ball mills mainly use induction motors, reducers and the transmission mode of large and small open gears and the penetration rate of low-speed and high-torque permanent magnet motors is low.