Shenzhen XH Technology Co., Ltd. |

|

Verified Suppliers

|

|

Colorful Silver Mirror Acrylic Sheet 8x4 Decorative Wall Panel

Silver plexiglass acrylic sheet 8x4 colorful decorative wall panel

acrylic mirror plastic panel

1. Product Description

As a new type of decorative material,

acrylic mirror has a variety of good properties and is deeply loved

by all walks of life. However, acrylic mirrors also have their

fragile side. In order to better use and maintain acrylic mirrors,

you must know these things about acrylic mirrors.

1 Thermoforming process: The acrylic sheet

can be thermoformed, but the acrylic mirror cannot, because the

mirror coating will be damaged during the thermoforming process.

For non-planar mirrors such as wide-angle mirrors and concave

mirrors, the acrylic sheet is hot-bent and formed, and then the

mirror coating is electroplated.

2. Outdoor use: Prolonged exposure to the sun

will cause the acrylic mirror to deform and turn yellow, affecting

the use effect. If it is used outdoors, the service life of the

acrylic mirror will be significantly shortened.

3. Water absorption: Acrylic mirrors are easy to

absorb water, which will cause temporary bending of the mirror

surface in a humid environment. This is the characteristic of the

material, so it should be considered when using it, and it should

not be used in places with high humidity such as bathrooms and

windows. .

2. Parameter

| PROPERTIES | VALUES | RULES |

| Density | 1.19 g/cm3 | ISO 1183-1:2012 Method A |

| Rockwell Hardness | 112L | ISO 2039-2:1999 |

| Tensile Modulus | 3150MPa | EN ISO 527:2012 |

| Tensile Strength | 80.0MPa | EN ISO 527:2012 |

| Tensile Strain at Break | 3.2% | EN ISO 527-1:2012 |

| Water Absorption | 0.20% | ISO 62:2008 Method 1 |

| Total Luminous Transmittance | 93.4% | ISO 13468-1:1996 |

| Vicat Softening Temperature | 105℃ | ISO 306:2013 Method B50 |

| Light Ageing Test- UV Exposure | Grey scale: 5 | ISO 4892-3:2016 Cycle 1 |

| Mean Coefficient of Linear Thermal Expansion | 72×10-6 K-1 | ISO 11359-1:2014 |

| Compressive Stress at Yield | 129MPa | EN ISO 604:2003 |

| Flexural Strength | 120MPa | ISO 178:2013 |

| Compressive Yield Strength | 111MPa | ASTM D695-15 |

| Compressive Modulus | 3450MPa | ASTM D695-15 |

| Shear Strength | 59.7MPa | ASTM D732-17 |

| Deflection Temperature under Load | 100.2℃ | ASTM D648-18 Method B |

| Modulus Elasticity | 2810MPa | ASTM D695-15 |

3. Advantages of acrylic mirror sheet

Hard Coated Acrylic Lenses Flame Resistance -

Durable sheets themselves are not self-igniting and

self-extinguishing. Heat resistance, cold resistance - test coated

acrylic lenses in the range of minus 30°C to 130°C without causing

distortion in quality changes, etc. Acrylic lenses have the

advantages of light weight, not easy to break, convenient molding

and processing, and simple coloring, which can meet the needs of

various lenses in our consumer life, so they are loved by a wide

range of users.

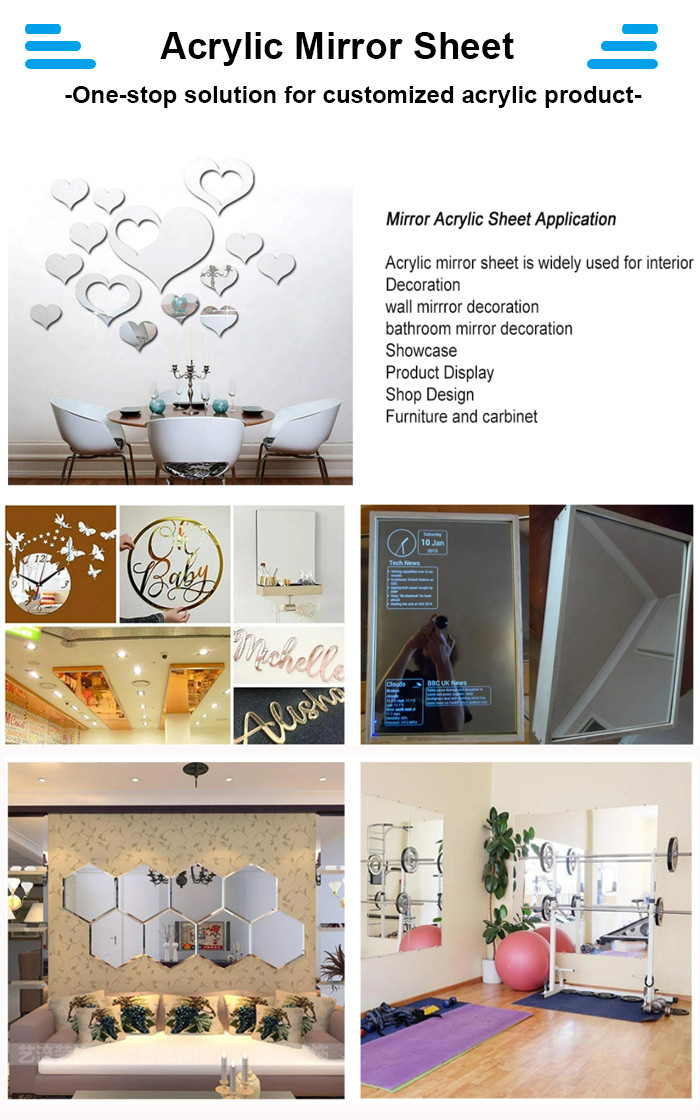

4. Acrylic mirror sheet Application

Acrylic mirrors or plexiglass mirrors, the main application areas are: interior decoration mirror wall stickers, showcases and points of sale, merchandise display design, store design, food service industry, and for safety reasons, light weight, shock-resistant acrylic plastic sheets are required. Places such as hospitals, prisons, kindergartens and mirrors for home gardens and school toys.

5. Acrylic mirror sheet Production process

7. Package and shipping

7.1. One piece of acrylic sheet package: double-sided covered with kraft paper or PE film, the cover film does not have any LOGO of our company.

7.2. Tray package: the total weight of each pallet is about 2 tons, the bottom is wooden pallet or iron pallet, and the surrounding is packed with corrugated paper.

7.3. The packaging method of the whole container: 20-23 tons (about 3000 pieces) 20-foot container, 10-12 pallets.