Zhangjiagang Beisu Machinery Co., Ltd. |

|

Verified Suppliers

|

Twin screw extruder 16-63mm PVC Electrical Conduit Double Pipe Production Line

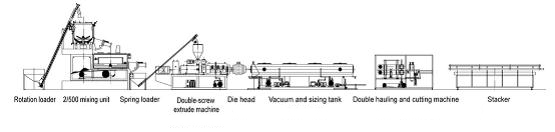

Layout:

PVC Raw material+additive→Mixing Unit→Auto Feeder→Conical Twin-screw Extruder→-Moulds→Vacuum calibration tank→Haul-off→Cutting Machine→Stacker

Summary:

1. Maximum Capacity: it can reach 5-7 ton per 24 hours according to the formula of CACO3

2. Water supply:≤25℃,≥0.3Mpa

3. Air supply:5-6m³/min,>0.5 Mpa

4. Temperature:0-40℃

5. Humidity:95% no condensation

6. Installation power:89kw

7. Total Length:21 meters

Applications:

1. Electrical piping system

2. Underground duct

Features specifications:

1. It produces twin pipe of two different diameters at the same time out of one mould.

2. Results in high production (125 kg/hr – 200kr/hr) even for smaller sizes of pipe.

3. Special conical twin screw extruder can take high filler loading as compared to parallel twin screw extruder.

4. Counter rotating conical twin screw machined on CNC make thread milling machines by simulation software for better performance

5. Bi-metallic screw & barrel can be provided for getting two-three times more lifespan than nitrided screw & barrel.

Main technical parameter:

| Pipe Range | 16-40mm | 16-63mm |

| Extruder Model | SJSZ51/105 | SJSZ65-132 |

| Extruder power | 22Kw | 37Kw |

| Extrusion Capacity | 135Kg/h | 250Kg/h |

| Max.Production Speed | 2*8m/min | 2*10m/min |

Zhangjiagang Beisu Machinery has a professional and dedicated after-sales service team to provide customers with a full range of responsible and reliable service. Our customer service work is divided into three phases: pre-sales program discussion and design, production tracking and installation and commissioning, and after-sales service and maintenance.

Pre-sales program discussion and design:

According to the customer's actual crushing or processing line requirements, provide customers with the corresponding professional knowledge explanation; at the same time, our engineering team selects the equipment model for you, customizes the most reasonable and effective crushing scheme, and ensures the perfect combination of our equipment and site layout. Create the greatest value and leave you carefree.

We provide customers with the design of the production line process, and truly design a satisfactory and reasonable production line for customers. Often, in order to meet the special needs of our customers and achieve the best results, we will make non-standard design changes to our products and treat every customer with care.