Zhangjiagang Beisu Machinery Co., Ltd. |

|

Verified Suppliers

|

Three layer 16-160mm PPR Co-extrusion Composite pipe extrusion line

Specification:

The production process of the PP-R pipe is an extrusion molding

process. First, the PP-R raw material in the hopper enters the

extruder by its own weight, and is heated and extruded in the

extruder barrel, and fully plasticized from the extruder port. The

die is extruded and enters the setting table. After the shaping,

the pipe is passed through the tractor and cut by the cutting

machine. The pipe is cut by the cutting machine and the pipe is

inspected and put into storage. The corresponding fittings are

produced by injection molding.

Pipe production process: PP-R raw material → vacuum suction feeding

→ hopper storage → feeding → extrusion molding → cooling setting →

traction → cutting → inspection → storage

Pipe production process: PP-R raw material → conveying and feeding

→ hopper storage → feeding → heating and melting → extrusion

molding → cooling and setting → mold opening → inspection →

storage.

Pipe extrusion parameters: (1) screw speed 5 ~ 38r / min (2) barrel

temperature distribution 1 ~ 2 area 180 ~ 190 ° C 3 ~ 4 area 200 ~

210 ° C mold temperature 200 ° C traction speed 2 ~ 20m / min pipe

fittings Injection parameters: (1) barrel temperature distribution

barrel rear 160 ~ 170 ° C barrel middle 200 ~ 230 ° C barrel front

180 ~ 200 ° C (2) nozzle 170 ~ 190 ° C (3) mold 40 ~ 80 ° CPP The

defective products produced in the -R pipe production process can

be reused after being crushed, which improves the utilization rate

of raw materials, reduces production costs, and improves economic

efficiency.

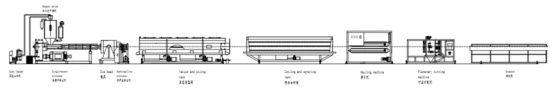

Layout:

Raw material+additive→Mixer→Auto Feeder→Hopper dryer→Single screw Extruder→-Moulds→Vacuum calibration tank→Spray Cooling Tank→Haul-off Unit→Cutting Unit→Stacker

Details specification pictures of PPR pipe production line by BEISU Machinery:

Traditional extruder:

The use of a smooth barrel provides limited friction, resulting in a significant reduction in the solids delivery efficiency of the extruder, resulting in lower yields for conventional smooth extruders and more difficult for extrusion of materials with high viscosity and low coefficient of friction. This greatly limits the application of single screw extruders.

IKV extruder with slotting in the feed section:

The groove is formed on the inner surface of the barrel feeding section, which helps to improve the friction coefficient between the plastic particles and the inner surface of the barrel, and hinders the plastic particles from sliding axially, thereby improving the solid conveying efficiency and finally greatly increasing the output. According to the different direction of the groove, it is divided into a straight groove and a spiral groove.

Main technical parameter:

| Model | Pipe Diameter | Output | Haul-off Speed | Total Power | Line Length |

| PPR-63 | 16-63mm | 100-120kg/h | 10m/min | 75kw | 35m |

| PPR-110 | 40-110mm | 180-220kg/h | 6m/min | 145kw | 38m |

| PPR-160 | 50-160mm | 200-250kg/h | 6m/min | 150kw | 38m |