SUZHOU MEIHAO HEAT STAKING TECHNOLOGY CO.,LTD. |

|

Verified Suppliers

|

|

HF-800 Split-Type Hot Air Cold Riveting Machine with Ethernet Communication Interface & 5-Program Storage

Riveting is a prevalent technique employed for the assembly of plastic components with other parts, eliminating the use of consumables such as adhesives and screws, thus promoting environmental sustainability. Additionally, employing riveting as an assembly method facilitates the design of lightweight products.

The machine utilizes the hot air cold riveting method. Initially, a specialized hot air rivet head is employed to initiate heating of the entire plastic rivet. After a predetermined heating time, the rivet uniformly softens, reaching an optimal state for riveting. Subsequently, a cold rivet head applies downward pressure, facilitating the cooling and shaping of the rivet, resulting in a strong and durable riveted connection between components.

This machine enables efficient and straightforward completion of riveting work, yielding reliable and robust riveted outcomes. The controller also features 5-program storage capability, allowing effortless program switching when transitioning between different riveting products without the need for parameter modification. This makes it highly suitable for riveting operations involving various distinct products.

Hot Air Cold Riveting Process:

(1) Assemble the components to be joined together and position the machine's hot air gun above the plastic rivet of the assembly;

(2) Apply heat to the plastic rivet using the hot air gun, causing it to soften to a suitable state for shaping. Immediately remove the hot air gun and position the cold air staking gun above the plastic rivet;

(3) The cold air staking gun rapidly applies downward pressure and blows cold air to cool and shape the plastic rivet. The cold air staking head disengages from the plastic rivet, resulting in a formed plastic rivet.

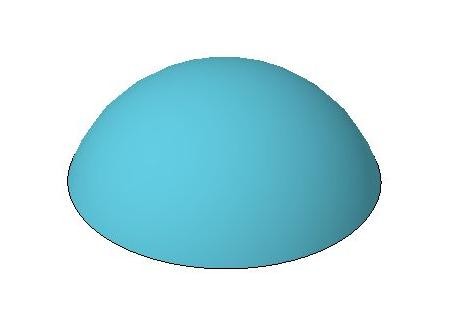

Common Shapes of Hot Air Cold Riveting Rivet Points

|  |  |

|  |  |

Specification Table for HF-800 Hot Air Cold Riveting Controller

| Model | HF-800 |

| Rated voltage | AC 200V~240V 50Hz |

| Rated power | 800W |

| Output voltage | AC 220V |

| Heating temperature set range | 50~600℃ |

| Riveting method | Hot air cold riveting |

| Thermocouple type | Type K |

| Communication interface | Ethernet |

| Number of program groups | 5 groups |

| Heating temperature segment | 1 segment |

| Parameter display and setting | 7-inch true color touch screen |

| Parameter password | Yes |

| Controller weight | 6KG |

| Controller dimensions | 243mm x 213mm x 183mm |

| Attention: Parameter changes caused by product upgrades or other factors will not be notified separately. The physical product shall prevail. Hereby declared! | |

These are the riveting outcome diagrams of the product

Company Profile :

Established in 2009, SUZHOU MEIHAO HEAT STAKING TECHNOLOGY CO.,LTD. is a professional company engaged in the research, development, production, sales, and service of plastic heat staking equipment. With over 14 years of industry experience, we are committed to providing high-quality heat staking equipment to our customers. Our products have gained significant market share domestically and are exported to multiple countries worldwide.

Our primary product lines include pulse plastic heat staking

equipment, plastic hot air cold staking equipment, and pulse heat

press welding equipment. These equipment are widely utilized in

industries such as automotive, electronics, and household

appliances. With a professional R&D team, we prioritize

technological innovation and product optimization within the

industry. We continuously innovate and improve our equipment to

meet the evolving needs of our customers.

If you require a custom-made product, please contact us first to obtain detailed information.

FAQ:

Q1: What are your competitive advantages?

A1: With over 14 years of experience, we are industry leaders in

various aspects. Additionally, we are direct manufacturers for all

our products, ensuring that you can purchase the products you need

at the most competitive prices.

Q2: How do you ensure product quality?

A2: For exclusive and customized designs, we first produce samples

for testing, ensuring that they meet customer satisfaction before

proceeding to mass production. All products undergo strict testing

procedures and are only packaged and shipped after passing quality

assessments.

Q3: What post-sales services do you offer?

A3: Upon receiving the products, our dedicated team of

professionals provides remote assistance to guide you through the

installation and utilization of our products.