SUZHOU MEIHAO HEAT STAKING TECHNOLOGY CO.,LTD. |

|

Verified Suppliers

|

|

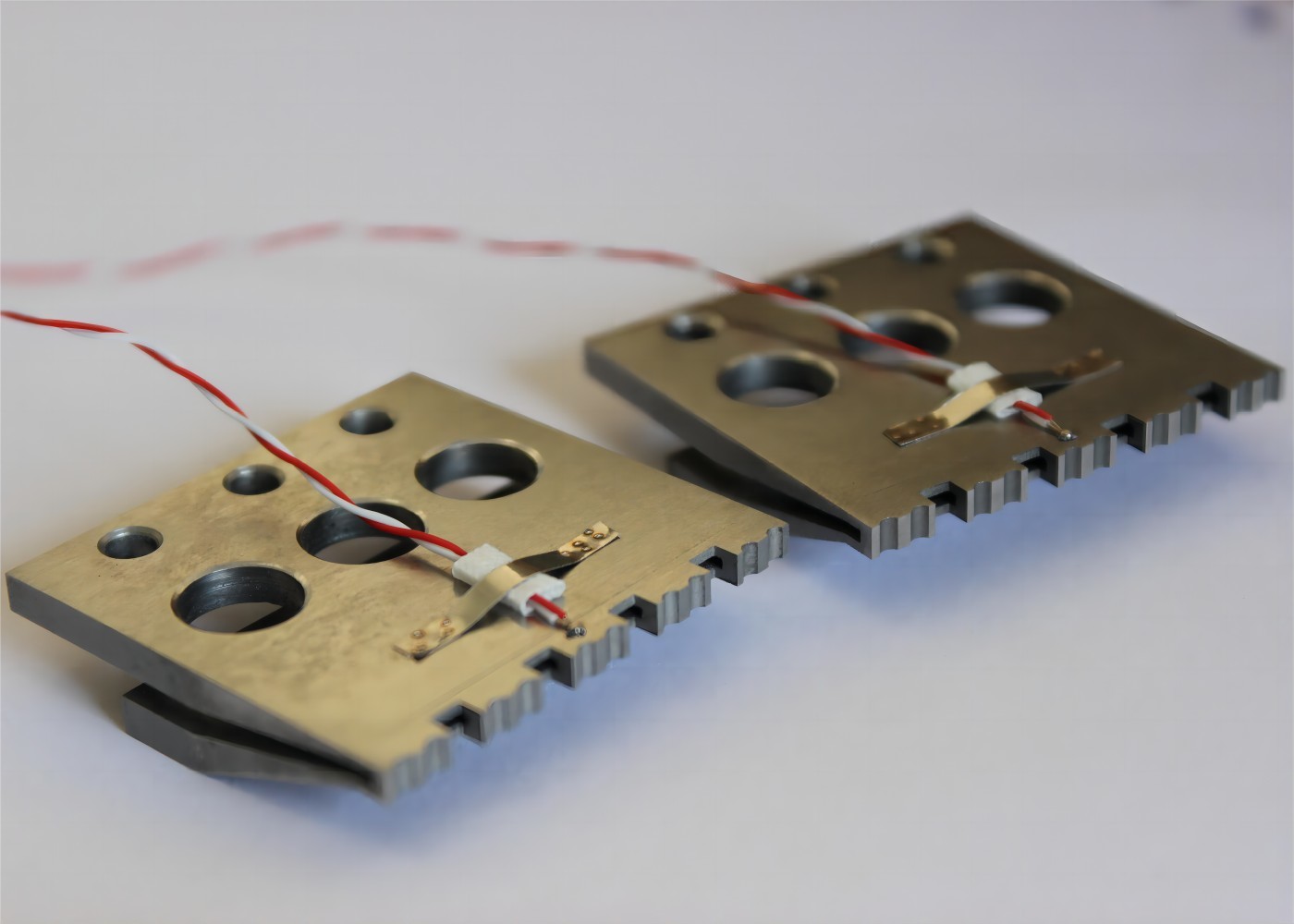

Customized Titanium Alloy Welding Head :

The welding head is made from titanium alloy, which offers excellent properties such as high strength, lightweight nature, exceptional corrosion resistance, and good heat conductivity. These characteristics make titanium alloy an ideal choice for various industries, including aerospace, automotive, and medical.

The customized titanium alloy welding head serves as a pulse welding heating element. It utilizes a built-in thermocouple on the welding head for real-time temperature feedback. By applying suitable current at the terminals of the welding head, the desired temperature is achieved. Heat is then conducted from the bottom of the welding head to the workpiece, facilitating the melting of solder on the welding components and forming a strong and secure weld joint. This welding process minimizes the thermal impact on neighboring components.

The customized titanium alloy welding head offers several advantages. It demonstrates exceptional wear resistance, enabling it to withstand abrasive conditions and maintain its integrity over time. Moreover, it exhibits high-temperature resistance, ensuring reliable performance even in high-temperature environments. Additionally, the welding head possesses outstanding corrosion resistance, making it suitable for applications exposed to corrosive elements.

The manufacturing of the customized titanium alloy welding head involves precision manufacturing processes such as CNC machining, precision grinding, and surface treatment. These processes guarantee the desired dimensions, surface finish, and overall quality of the welding head. The production of the welding head adheres to stringent quality standards, undergoing comprehensive inspections and tests to ensure compliance with the specified requirements and performance standards.

Application scenarios and examples of titanium alloy welding heads

| Fiber optic communication device FPC soldering | Mobile phone camera module assembly soldering | Lithium battery packaging |

|  |  |

The attached illustrations present several welding heads and demonstrate the welding results of this product in real-world production

Company Profile :

Established in 2009, SUZHOU MEIHAO HEAT STAKING TECHNOLOGY CO.,LTD. is a professional company engaged in the research, development, production, sales, and service of plastic heat staking equipment. With over 14 years of industry experience, we are committed to providing high-quality heat staking equipment to our customers. Our products have gained significant market share domestically and are exported to multiple countries worldwide.

Our primary product lines include pulse plastic heat staking

equipment, plastic hot air cold staking equipment, and pulse heat

press welding equipment. These equipment are widely utilized in

industries such as automotive, electronics, and household

appliances. With a professional R&D team, we prioritize

technological innovation and product optimization within the

industry. We continuously innovate and improve our equipment to

meet the evolving needs of our customers.

If you require a custom-made product, please contact us first to

obtain detailed information.

FAQ:

Q1: What are your competitive advantages?

A1: With over 14 years of experience, we are industry leaders in

various aspects. Additionally, we are direct manufacturers for all

our products, ensuring that you can purchase the products you need

at the most competitive prices.

Q2: How do you ensure product quality?

A2: For exclusive and customized designs, we first produce samples

for testing, ensuring that they meet customer satisfaction before

proceeding to mass production. All products undergo strict testing

procedures and are only packaged and shipped after passing quality

assessments.

Q3: What post-sales services do you offer?

A3: Upon receiving the products, our dedicated team of

professionals provides remote assistance to guide you through the

installation and utilization of our products.