Shenzhen Zion Kaifull Automation Technology Co., Ltd. |

|

Verified Suppliers

|

|

High precision ZPLE090-L3-(64, 80, 100, 125, 140, 175, 200, 250, 280, 350)-S2-P2 series planetary gearboxs are widely used in industrial automation fields, such as,

The working principle of the planetary reducer is mainly based on the transmission of the planetary wheel system. The interaction of the internal gears achieves speed reduction and torque increasing.

Its internal structure mainly includes solar wheels, planet wheels, and inner gears circle. The solar wheel is located in the center and is driven by the input shaft; the planet wheel is located between the solar wheel and the inner gear circle, and there are usually multiple planetary wheels. The inner gears are fixed on the shell of the reducer. When the solar wheels rotate, the planetary wheels generate rotation under its action, and at the same time rotate along the orbits of the inner gear. This unique movement method enables the planetary reducer to achieve a higher deceleration ratio.

In addition, the design of the planetary reducer has the characteristics of compact structure, high transmission efficiency, and low noise, which are widely used in the industrial field.

Kaifull PRMCAS Planetary reducer has the following characteristics:

High drive efficiency: The transmission efficiency of planetary reducer is usually high, and can reach more than 90%. This is because in the planetary gear transmission, multiple gears pass the power at the same time, reducing the transmission loss.

Large torque output: Planetary reducer can achieve larger torque output through multi-stage gear transmission. Each planet wheel can withstand part of the load, so that the overall load is scattered to multiple gears, increasing the torque output capacity.

Compact structure: The planetary reducer has a compact structural design. The gear device is located in a closed outer gear and occupies relatively small space. This makes the planetary gearbox special advantageous in limited space applications.

High rigidity and accuracy: Planetary reducer has high rigidity and accuracy, which can provide accurate output movement and position control. This makes the planetary reducer very important in applications that require precision exercise and positioning, such as industrial machinery and automation equipment.

Stable output movement: Due to the coordination of multiple gears, the planetary reducer provides smooth output motion, which reduces the production of vibration and noise. This is very important for applications that require low noise and stable operation.

Rich specifications and options: Planetary reducer has a variety of configurations and options, such as different deceleration ratios, input and output shaft layout, attachment and sensor installation to meet the requirements of specific applications.

| Matched Motors | Servos 400W, 750W, | |||||||||

| Reduction Ratios | 64:1 | 80:1 | 100:1 | 125:1 | 140:1 | 175:1 | 200:1 | 250:1 | 280:1 | 350:1 |

| Backlash (arcmin) | <15arcmin | |||||||||

| Rated Input Speed (rpm) | 3000 | |||||||||

| Max. Input Speed (rpm) | 6000 | |||||||||

| Rated Outout Torque (N.m) | 120 | 120 | 120 | 132.5 | 120 | 132.5 | 120 | 132.5 | 120 | 132.5 |

| Max. Output Torque (N.m) | 240 | 240 | 240 | 265 | 240 | 265 | 240 | 265 | 240 | 265 |

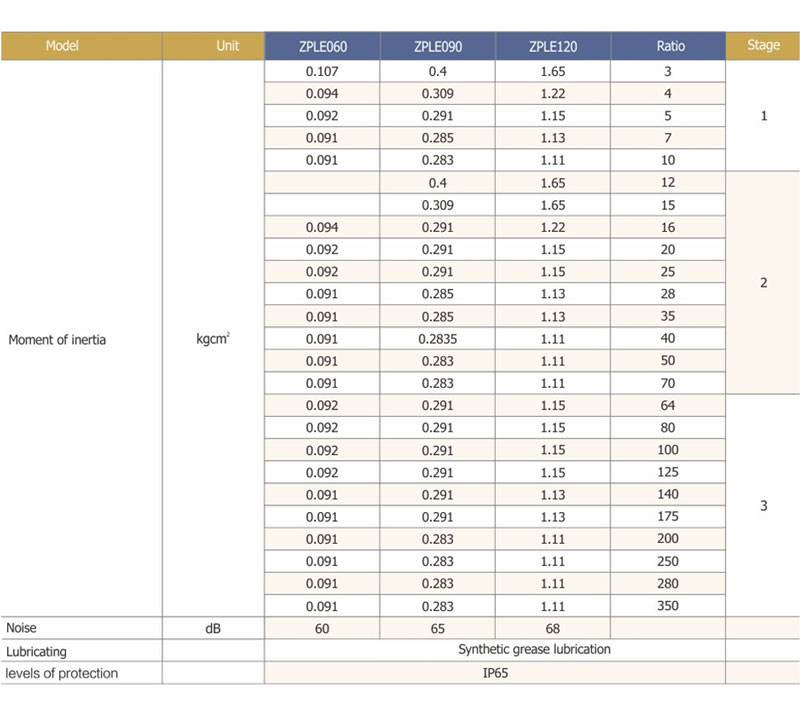

| Rotor Inertia (Kgcm2) | 0.291 | 0.291 | 0.291 | 0.291 | 0.291 | 0.291 | 0.283 | 0.283 | 0.283 | 0.283 |

| Max. Radical Force (N.m) | 1020 | |||||||||

| Max. Axial Force (N.m) | 850 | |||||||||

| Average Lifetime (hours) | >20000 | |||||||||

| Noise Level (dB) | 65 | |||||||||

| IP Grade | IP65 | |||||||||

| Lubrication | Long-term Grease | |||||||||

| Efficiency | 95% | |||||||||

| Weight (Kg) | 8.3 | |||||||||

| Shaft Adaptor | Available | |||||||||

Note: If you find difficulty in model selection, just kindly contact us and the most proper reducer will be recommended.

Kaifull Automation, is one of the leading middle and high-end motion control products&System vendors in China with strong R&D capabilities and rich indutrial application experiences of more than 20 years.

Such as Steppers (stepper drivers, open and closed loop motors, geared stepper motors, motors with brake, integrated drivers and motors), Linear Steppers (drivers and motors), Servos (drivers and motors, other brands), Brushless(Drivers and motors, other brands), Linear Motors (Drivers and motors), Variable Frequency Drives/Inverters(other brands), Electric Spindles(Other brands), Planetary and Harmonic Reducers, Motion Controllers(other brands), etc.

Company

|

Products & Solutions

|

Production |

|

|

|

Expertise

|

Services

|

Market |

|

|

|

5. TechnicaL Support and Services

Standard products delivery within 10-15days.

Professional and high quality customization available.

7*24 technical services via email, Teamviewer, social medias, customer visiting etc.

Site support or training for dealers both in China and customer countries.

18months or 24months warrenty for most products, epcial products will be exceptional, such as spindle motopr bearings for 6months.

Sending pareparts for repairing or repair in China and send back to customers in new shipments.

Mostly FOB, DAP or as per customer need and payment by T/T through bank accounts prefered.

Support all shipment methods, such as express, air, sea, or Sino-euro train shipment etc.