Shenzhen Zion Kaifull Automation Technology Co., Ltd. |

|

Verified Suppliers

|

|

ZLSH32-H Series High Torque&Speed Low Noise Hamonic Gear Reducers Wave Generator for CNC machine Industrial Automation

1. Products Overview

Harmonic reducers, or harmonic gearboxes are mainly composed of four basic components: wave generator, flexible gear, flexible bearing, and rigid gear. Harmonic transmission reducer is a kind of flexible bearing with a wave generator to produce controllable elastic deformation of the flexible gear and it transforms the force by meshing with rigid teeth.

PRMCAS Harmonic Gear Reducers Features and Advantages as the followings,

•Simple structure. Harmonic reducer is usually composed of three basic parts, namely wave generators, soft wheels and rigid wheels.

•Small size and lightweight. Compared with ordinary reducers, the volume of the harmonic reducer can be reduced by about 2/3, and the weight can be reduced by about 1/2.

•The transmission ratio is large. The range of single -stage harmonic gear transmission ratio is 70 to 320, with 1,000 of certain devices, and a multi -stage transmission ratio of more than 3,000.

•Strong carrying capacity. Due to the meshing of multiple teeth at the same time, the load carrying capacity of the unit area is high.

•High transmission accuracy. Multiple teeth’s meshing helps the uniformity of errors, the transmission error is small, and the zero backlash mesh can be achieved.

•High drive efficiency. The relative sliding speed of the wheel teeth is low, the wheel tooth wear is small, and the efficiency is high (up to 69%~ 96%).

•Smooth exercise. Due to the meshing, there is no impact on both sides of the gear, and the exercise is stable.

•Suitable for closed space. Using the flexible characteristics of the soft wheel, the harmonic reducer can work normally under the operating conditions of the closed space and the medium.

•Long life. Due to structural design and material selection, harmonic reducers have a long service life.

•Little noise. Due to the stable transmission, the noise level of the harmonic reducer is relatively low.

Applications

Industrial robot. Harmonic reducer is used to connect motors and execution agencies to provide high -precision and stable motion control.

Service robot. In the fields of medical care, care and logistics, harmonic reducer is used to improve the exercise accuracy and reliability of robots.

Robotic arm. Harmonic reducer is used for end actuators to achieve fine operation.

Precision processing field. Harmonic reducer is used to control speed and provide large torque to ensure the stability of the equipment and high -precision processing molding.

The field of aerospace. Harmonic reducer is used to ensure the accuracy and maneuverability of satellite transition, as well as the movement of the landing gear and the steering gear.

The field of medical device. The harmonic reducer is used to improve the stability and accuracy of the arm movement of the surgical robot, as well as the fields of blood transport equipment, monitoring and medical machinery. The harmonic reducer plays an important role in modern industry and automation systems with its high -precision, high torque, small volume and low noise systems with its high -precision, high torque, small volume and low noise.

Others, such as carton packaging machinery, medical machinery, measurement/analysis/test machine, large telescope, meteorological equipment, advanced instrumentation, optical manufacturing equipment, semiconductor manufacturing devices, crystal manufacturing equipment, FPD manufacturing devices, communication devices, aerospace machines, aerospace machines , CNC machine tools, radar and other precision transmission systems such as satellite ground receiving equipment.

2. ZLSH32-H Series Harmonic Geabox Drawings and Technical Specifications

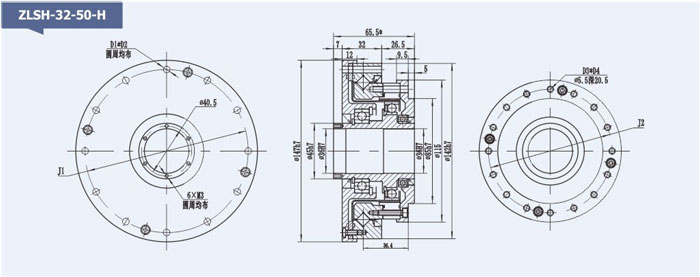

ZLSH32-50-H, reduction ratio 50:1 harmonic gear reducer mechanical drawings and main technical specifications as bellow,

| Rated Torque @2000rpm | Max. Torque of Start and Stop | Max. Average Torque | Max. Instantaneous Torque | Max. Input Speed | Permissible Average Input Speed | Life Time |

| N.m | N.m | N.m | N.m | rpm | rpm | Hours |

| 76 | 222 | 119 | 420 | 4800 | 3500 | >14000 |

| Angle Accuracy | Hysteresis | Start Torque | Acceleration Torque | Buckling Torque | Max. Backlash | Lubrication |

| arcmin | arcmin | N.m | N.m | N.m | arcsec | Lifelonge Grease |

| 1 | 2 | 85 | 51 | 1750 | 5.4 | Noise <60dB |

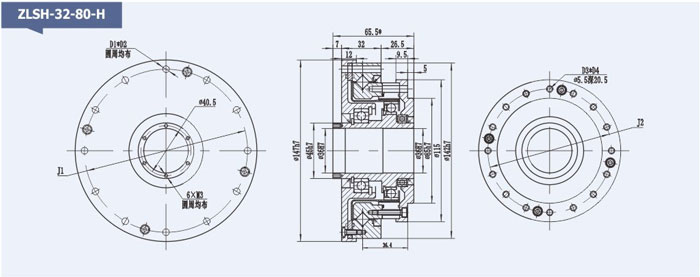

ZLSH32-80-H, reduction ratio 80:1 harmonic gear reducer mechanical drawings and main technical specifications as bellow,

| Rated Torque @2000rpm | Max. Torque of Start and Stop | Max. Average Torque | Max. Instantaneous Torque | Max. Input Speed | Permissible Average Input Speed | Life Time |

| N.m | N.m | N.m | N.m | rpm | rpm | Hours |

| 118 | 314 | 184 | 625 | 4800 | 3500 | >14000 |

| Angle Accuracy | Hysteresis | Start Torque | Acceleration Torque | Buckling Torque | Max. Backlash | Lubrication |

| arcmin | arcmin | N.m | N.m | N.m | arcsec | Lifelonge Grease |

| 1 | 2 | 74 | 70 | 1750 | 5.4 | Noise <60dB |

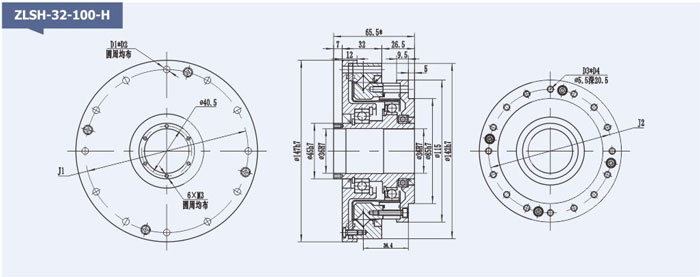

ZLSH32-100-H, reduction ratio 100:1 harmonic gear reducer mechanical drawings and main technical specifications as bellow,

| Rated Torque @2000rpm | Max. Torque of Start and Stop | Max. Average Torque | Max. Instantaneous Torque | Max. Input Speed | Permissible Average Input Speed | Life Time |

| N.m | N.m | N.m | N.m | rpm | rpm | Hours |

| 137 | 345 | 238 | 712 | 4800 | 3500 | >14000 |

| Angle Accuracy | Hysteresis | Start Torque | Acceleration Torque | Buckling Torque | Max. Backlash | Lubrication |

| arcmin | arcmin | N.m | N.m | N.m | arcsec | Lifelonge Grease |

| 1 | 2 | 72 | 86 | 1750 | 5.4 | Noise <60dB |

Note: If you find difficulty in model selection, just kindly contact us and the most proper reducer will be recommended.