Shenzhen Zion Kaifull Automation Technology Co., Ltd. |

|

Verified Suppliers

|

|

ZLSH17-S Series High Torque&Speed Low Noise Hamonic Gear Reducers Wave Generator for CNC machine Industrial Automation

1. Products Overview

Harmonic reducers, or harmonic gearboxes are mainly composed of four basic components: wave generator, flexible gear, flexible bearing, and rigid gear. Harmonic transmission reducer is a kind of flexible bearing with a wave generator to produce controllable elastic deformation of the flexible gear and it transforms the force by meshing with rigid teeth.

PRMCAS Harmonic Gear Reducers Features and Advantages as the followings,

The transmission ratio is larger. The ratio of a single-stage harmonic gear transmission rate is 70 ~ 320:1, can reach up to 1,000:1 in certain harmonic reducers, and the multi-stage transmission speed ratio can reach more than 30,000:1.

High carrying capacity. This is because the number of teeth that meshing at the same time in the harmonic gear transmission can be more than 30% of the total number of teeth at the same time, and the soft wheels use high-intensity materials, and the tooth is connected with facial contact.

High transmission accuracy. This is because the number of teeth in the harmonic gear transmission at the same time and, the multi-tooth mesh has a mutual compensation effect on the error, so the transmission accuracy is higher. In the case of the same gear accuracy level, the transmission error is only about 1/4 of ordinary cylindrical gear transmission.

High drive efficiency and stable exercise. Because the soft wheel teeth moved a uniform radial movement during the transmission, even if the input speed is very high, the relative slip speed of the wheel teeth is still extremely low. So the wheel's teeth wear is small, high efficiency (can reach 69%~ 96%). Due to the entry and meshing, both sides of the gear participated in the work, so there was no impact, and the exercise was stable.

Simple structure, small number of parts, and convenient installation. There are only three basic components, and the input and output shaft coaxial rays, so the structure is simple and easy to install.

Small volume and light weight. Compared with the regular reducer, when the output torque is the same, the volume of the harmonic gear reducer can be reduced by 2/3, and the weight can be reduced by 1/2.

Suitable for closed space application. Using the flexible characteristics of soft wheels, this valuable advantage of rotation is incomparable to other transmission.

Applications

Mechanical automation field

In the field of mechanical automation, harmonic reducers are mainly used in automated equipment such as various robotics, printing machines, heat molding machines, and packaging machines. It can achieve high -precision, high speed, and high rigid transmission control. For example, on the industrial production line, the harmonic reducer can effectively improve the production efficiency and stability of the equipment, reduce the failure rate and maintenance time.

The field of aerospace

In the field of aerospace, harmonic reducers are mainly used for high -precision transmission control equipment such as aviation control compartment, satellite navigation equipment, and rocket launch platforms. Harmonious and low -reverse characteristics of harmonic reducer enable it to meet the requirements of space control accuracy, and at the same time can greatly reduce the weight of the equipment and improve the performance of the entire system.

The field of electronics and electronics

In the field of electrical electronics, harmonic reducers are mainly used for high -speed precision transmission controls such as various robots, CNC cutting machines, and thermal molding equipment. Harmonic reducer's high rigidity, high efficiency, low noise, and high -precision features have been widely used in the power electronics field.

2. ZLSH17-S Series Harmonic Geabox Drawings and Technical Specifications

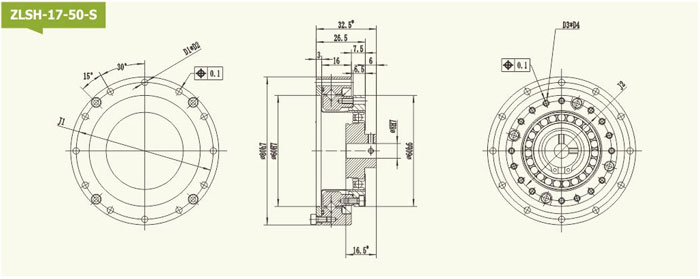

ZLSH17-50-S, reduction ratio 50:1 harmonic gear reducer mechanical drawings and main technical specifications as bellow,

| Rated Torque @2000rpm | Max. Torque of Start and Stop | Max. Average Torque | Max. Instantaneous Torque | Max. Input Speed | Permissible Average Input Speed | Life Time |

| N.m | N.m | N.m | N.m | rpm | rpm | Hours |

| 16 | 39 | 28.5 | 77 | 8500 | 3500 | >14000 |

| Angle Accuracy | Hysteresis | Start Torque | Acceleration Torque | Buckling Torque | Max. Backlash | Lubrication |

| arcmin | arcmin | N.m | N.m | N.m | arcsec | Lifelonge Grease |

| 1.5 | 2 | 34 | 16 | 270 | 20 | Noise <60dB |

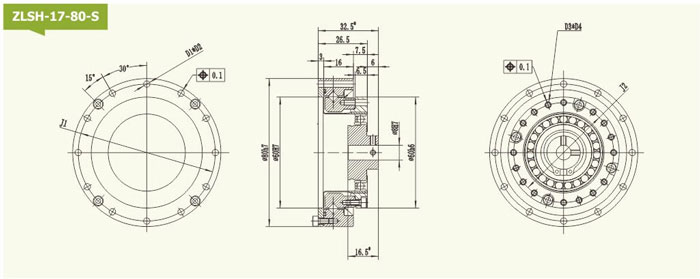

ZLSH17-80-S, reduction ratio 80:1 harmonic gear reducer mechanical drawings and main technical specifications as bellow,

| Rated Torque @2000rpm | Max. Torque of Start and Stop | Max. Average Torque | Max. Instantaneous Torque | Max. Input Speed | Permissible Average Input Speed | Life Time |

| N.m | N.m | N.m | N.m | rpm | rpm | Hours |

| 16 | 39 | 28.5 | 77 | 8500 | 3500 | >14000 |

| Angle Accuracy | Hysteresis | Start Torque | Acceleration Torque | Buckling Torque | Max. Backlash | Lubrication |

| arcmin | arcmin | N.m | N.m | N.m | arcsec | Lifelonge Grease |

| 1.5 | 2 | 43 | 22 | 270 | 13 | Noise <60dB |

Note: If you find difficulty in model selection, just kindly contact us and the most proper reducer will be recommended.