Shenzhen Zion Kaifull Automation Technology Co., Ltd. |

|

Verified Suppliers

|

|

Y2SS3-S Adaptive 8.0A 2 Phase closed loop Step Servo Drive with Encoders Output for Industrial Automation

1. Products Overview

A closed-loop step motor driver is a motion control driver that receives control singles and output proper driving current for a stepper motor and control its movement. Step motor and driver constitute a stepping motion control system, and the performance not only depends on the stepper motor, but also the stepper driver.

The advantages of closed-loop step motor drives include: no step loss, higher torque, higher precision, good stability, low power consumption, fast response speed, lower noise etc.

Closed-loop Step drives are widely used in factory automation, carving machines, electronic product manufacturing, logistics sorting, robots, various special automation equipment, medical equipment, CNC machine tools, laser equipment, printing machinery, material processing, safety system, navigation system, industrial test and measurement etc. There are many fields such as measurement and metering systems.

If u cannot find proper stepper driver or motor, could u kindly contact us any time? We will recommend the most suitable for you with great compatitiveness.

2. Main Technical Specifications

Characteristic

◆ DC input step servo driver

◆ Adaptive motor and load, adjust current automatically, 0.5-8.0A

◆ Input voltage: 24 - 75 VDC

◆ Pulse + direction / double pulse control mode

◆ 16 stall subdivide optional

◆ Control signal 5-24V compatible

◆ Multiple electrical protection

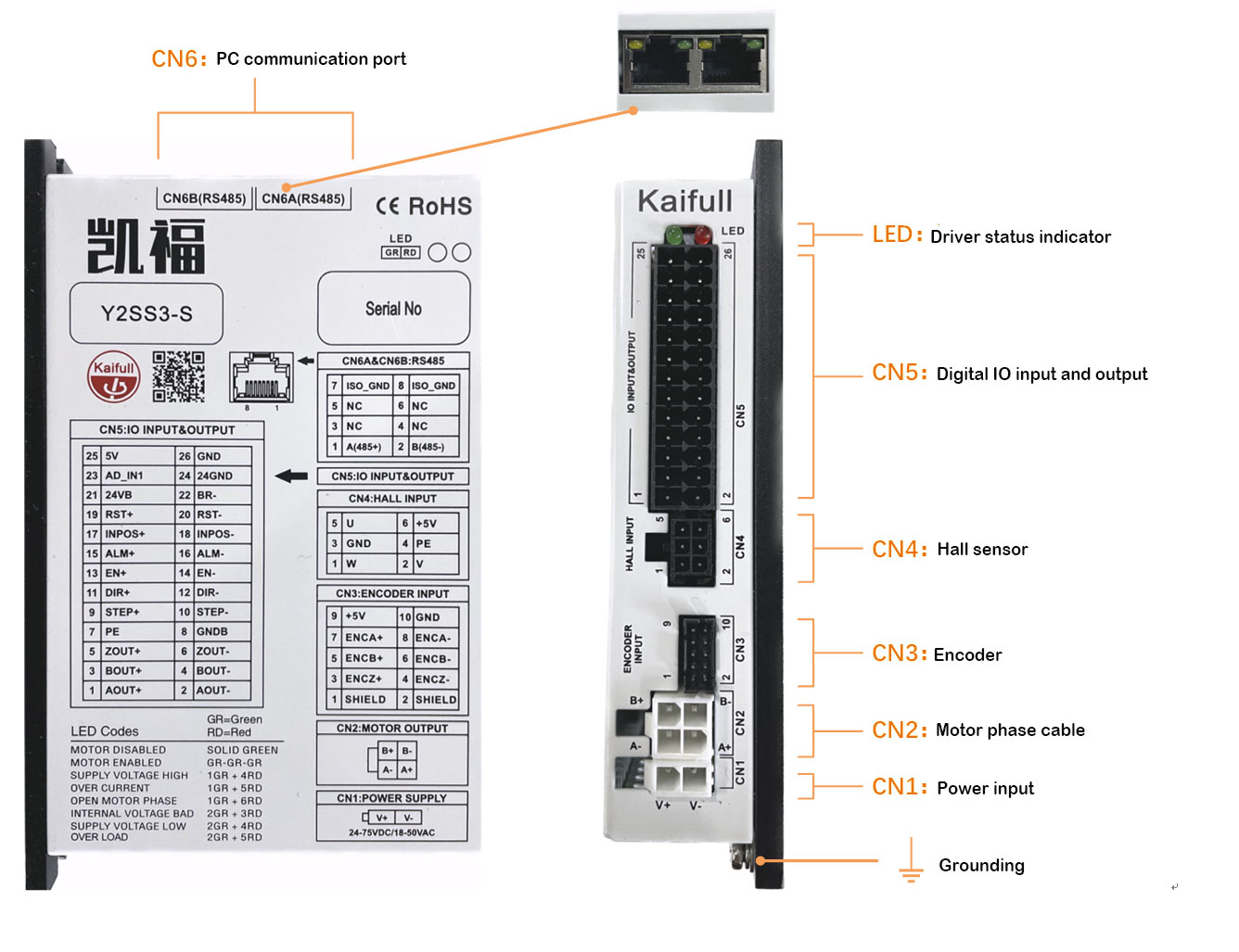

3. Stepper Driver External Interfaces

4. LED Status Indicator Description

Based on LED status indicators, driver working status or abnormal causes can be identified.

| Display | Color | Explain |

| POWER | Green | The green light flashes when the driver is normal |

| ERROW | Red | When the driver went wrong, the traffic lights flashing alternately |

Status | Failure | Causes |

green flicker | Drive normal | -- |

green always on | Drive not enabled | EN port has high level input |

red and 1 green | Drive temperature is too high | Need to strengthen the heat |

red and 1 green | Drive power input over voltage | Power supply voltage is greater than 75V |

red and 1 green | Drive over current | Motor wiring fault or poor contact |

red and 1 green | Motor winding open circuit | The motor is not connected well |

red and 2 green | Drive internal voltage error | Power is too low |

red and 2 green | Drive power input under voltage | Power supply voltage is less than 24V |

5 red and 2 green | Over load | Exceeded load |

5. Power Connection

| Terminal identification | Power supply connection |

| V+ | Positive pole |

| V- | Negative pole |

6. CN3 Encoder Connection

The connection terminal and extension line of the encoder are designed to be directly inserted, so that self-wiring is considered unnecessary.

7. CN4 Hall Input

| Switch setting | Description | Switch setting | Description |

| CN4 .5 | U | CN4 .6 | 5V+ |

| CN4 .3 | GND | CN4 .4 | PE |

| CN4 . 1 | W | CN4 .2 | V |

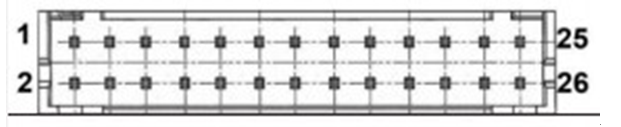

8. CN5 I/O Control Signal

I/O control signal | Input/ Output |

Reference | ||

| CN5 . 1 | AOUT+ | Encoder A+Output |

Fig. 2 | |

| CN5 .2 | AOUT- | Encoder A-Output Encoder B+Output Encoder B-Output Encoder Z+Output Encoder Z-Output | ||

| CN5 .3 | BOUT+ |

O | ||

| CN5 .4 | BOUT- | u t p u t | ||

| CN5 .5 | ZOUT+ | |||

| CN5 .6 | ZOUT- | |||

| CN5 .7 | PE | Driver grounding | ||

CN5 .8 |

GNDB | Encoder ground wire (connected to the internal GND of upper computer) | ||

| CN5 .9 | STEP+ | Input | STEP+: pulse positive terminal |

Fig. 4 |

| CN5 .10 | STEP- | STEP-: pulse negative terminal | ||

| CN5. 11 | DIR+ | DIR+: positive direction | ||

| CN5. 12 | DIR- | DIR-: negative direction | ||

CN5 .13 |

EN+ | EN+ positive terminal (normally closed) | ||

| CN5. 14 | EN- | Output | EN- negative terminal (normally closed) | |

| CN5. 15 | ALM+ |

Input | Alarm output +(100mA) |

Fig. 1 |

| CN5 .16 | ALM- | Alarm output -(100mA) | ||

| CN5. 17 | INPOS+ | In-place signal output +(100mA) | ||

| CN5 .18 | INPOS- | In-place signal output -(100mA) | ||

| CN5 .19 | RST+ | Alarm reset+ |

Fig. 4 | |

| CN5 .20 | RST- | Alarm reset- | ||

CN5 .21 |

24VB | Output

Input | 24V Brake power supply Brake output +(24V1A) |

Fig. 3 |

| CN5 .22 | BR- | Brake output -(24V1A) | ||

| CN5 .23 | AD- IN1 | Output | Analog input | |

| CN5 .24 | 24GND | Brake power supply 0V | ||

| CN5 .25 | 5V | Potentiometer power supply + 5 V |

Fig. 5 | |

| CN5 .26 | GND | Potentiometer power supply 0V | ||

9. CN6 RS485 Connection

| Switch setting | Switch setting | Rotation position | Switch setting |

| CN6 .7 | ISO_GND | CN6 .8 | ISO_GND |

| CN6 .5 | NC | CN6 .6 | NC |

| CN6 .3 | NC | CN6 .4 | NC |

| CN6 . 1 | A(485+) | CN6 .2 | B(485-) |

10. Control Signals Connections

Input connections:

Output connections:

9. Mechcanical Dimenssions