Shenzhen Zion Kaifull Automation Technology Co., Ltd. |

|

Verified Suppliers

|

|

42AHS054 Dual Shaft Six Wires 2 Phase Hybrid Stepper Motor

1. Products Overview

Step motor is an executive agency that converts electrical pulses into corner displacement. You can control the angle displacement by controlling the number of pulses to achieve the purpose of accurate positioning. At the same time, you can control the speed and acceleration of the motor rotation by controlling the pulse frequency to achieve the purpose of the speed regulation.

The hybrid step motor is currently the most widely used step motor, and everyone is familiar with the stepper motor. Here, we briefly introduce how to choose the right step motor for our applications.

How to choose the right step motor for our applications?

The choice of stepping motor torque

The torque of the stepping motor is similar to the "power" of traditional motors. Of course, there is an essential difference. The physical structure of the stepping motor is completely different from AC and DC motors and the output power can be variable.

Generally, we select the motor size according to the torque need in operation. For example, if the torque needed is less than 0.8N.M, frame size 20/28/35/39/42mm stepper motors are suitable. If the required torque is about 1N.M, select 57mm motor. When the required torque is several N.M or even more, usually selected stepping motors with frame size 86/110/130mm or bigger.

The stepping motor speed selection

Special consideration should be taken for the speed of the target stepper motor. Because the output torque of the motor is inversely proportional to the speed. That is to say, when the stepper motor speed is low (500-600 rpm or lower speed per minute), its output torque is larger. When the motor speed is increasing, the motor toque will be decreasing and especially when with the speed of 1000rpm and above.

Sometimes when high-speed motors are needed, the coil resistance, inductance and other indicators of the stepped motor must be considered carefully. Choose a motor with a slightly less inductance is better, as the output torque is normally higher. However, if want low speed and big torque, a stepper motor with inductance no less than 10mH is better.

Selection of no-load-starting frequency

This is a more important indicator for buying motors. If it is required to start and stop frequently within a short time, and the speed is about 1000 rpm (or higher), it is usually necessary to "accelerated startup", i.e need a motor with high no-load-starting frequency.

Phase selection

Regarding to the choice of the number of step motor phases, many customers do not pay enough attention. In fact, the performance of stepper motors with different phases are different. The more phases, the smaller the steps can be done, and the vibration at work is smaller. In most occasions, two-phase motors are enough. However, if higher performances needed, especially for precision or smoothness, 3-phase or 5-phase can be better.

Select the protection level

There are special step motors, such as water-proof and oil-proof, dust-proof for some special occasions. For example, underwater robots, or fountain etc. need waterproof motors.

Other special specifications

If u need special step motors, please contact us. Within the scope of technical permission, we are happy to provide you with customized services, including but not limited to, current, torque, speed, hollow shaft, dual axis, coder, band, belt Brakes, etc.

Although the stepper motor and its control technology are currently very mature, if not used properly, there may still be a situation of step loss, i.e. position error. Next, we will analyze the common causes and solutions of position errors.

The reasons for the position error of stepper motors

Large load inertia

When the inertia of the load driven by the stepper motor is large, its inertia will generate inertia force, causing the current waveform output by the stepper motor controller to be inconsistent with the actual required current waveform, resulting in inaccurate position of the stepper motor.

The stepper motor driver is not set correctly

Incorrect settings of the stepper motor driver, such as fine fraction, step angle, and other parameter settings, can also lead to an increase in the position error of the stepper motor.

The pulse signal output by the stepper motor controller is unstable

When the pulse signal output by the stepper motor controller is unstable, it can lead to inaccurate position of the stepper motor. This situation is more common when using long-distance transmission of control signals.

The stepper motor is damaged

The rotor or stator of the stepper motor may be damaged, or the bearings may be damaged, which can lead to positional errors in the stepper motor.

Methods to solve the position error of stepper motors

Control load inertia

The position error of the stepper motor can be reduced by reducing the load inertia. For example, when driving a stepper motor with inertia loads, methods such as installing shock absorbers and changing the load inertia mode can be used to reduce the load inertia.

Set the driver parameters correctly

Correctly set the subdivision and step angle parameters of the stepper motor driver to ensure the position accuracy.

Stable output pulse signal

High precision pulse generators or adjustable filters can be used to stabilize the output pulse signal and reduce the position error of stepper motors.

Replace damaged stepper motor components

When the stepper motor is damaged, it is necessary to replace the corresponding components in order to restore the normal operation of the stepper motor.

The Applications of Kaifull PRMCAS Hybrid Stepper Motors

Machine tools and engraving machines

The application of stepper motors in machine tools is also very common. In machine tools, stepper motors are used to control the feed and tool retraction, thereby achieving precision and speed in machining workpieces. It can achieve different processing effects, high speed, and high efficiency.

Automation equipment

The application of stepper motors in automation equipment is also very extensive. In automation equipment, stepper motors are used to control the position and speed of various moving components, thereby achieving automation control of the equipment. It can achieve different control effects, such as high speed and high stability.

Printing machines

Stepper motors are widely used in printers. In a printer, a stepper motor is used to control the movement of the print head, thereby achieving precise printing of text, images, and charts. It can achieve different printing effects, such as high definition, high speed, and high stability.

Automotive components

The application of stepper motors in automotive components is also very common. In automotive components, stepper motors are used to control the position and speed of car seats, rearview mirrors, windows, and doors, thereby achieving automated control of automotive components. It can achieve different control effects, such as high speed and high reliability.

Optical equipment

In optical equipment, stepper motors are widely used in modulators, fine-tuning, and other aspects. Because the action of stepper motors is very slow and the stepper angle can be adjusted, they are widely used in various optical positioning mechanisms, which can provide higher stability and accuracy for optical equipment.

Medical devices

Stepper motors are widely used in medical devices, especially in surgical instruments such as blades and cutters. The high-precision positioning of stepper motors can significantly improve the accuracy of surgery and make surgery safer. Stepper motors can also be used in devices such as pacemakers and syringes.

Precision positioning applications

Stepper motors can complete precise positioning tasks through quantitative motion and fixed step angles, which makes them widely used in various precision positioning equipment, such as optical equipment, textile equipment, computer embroidery machines, medical equipment, automation equipment, etc. These equipment usually require high-precision and stable positioning machinery, and stepper motors are perfect for such tasks.

In summary, stepper motors can be widely used in various fields due to their characteristics of quantitative motion and fixed stepper angle, providing more precise and efficient driving force for mechanical equipment to achieve higher production efficiency and quality.

2. Hybrid Stepper Motor General Technical Specifications

| Step Angle | 1.8° (2 Phase) |

| Step Angle Accuracy | 0.09° |

| Shaft Type | Dual, Dia. 5mm (Customizable) |

| Max. Temperature Rise | Less than 80 °C (Rated Current) |

| Max. Surface Temperatures | Max Allowed 100℃ |

| Ambient Temperature | -20 °C ~ +50 °C |

| Insulation Grade | 100 MΩ Min. , Class B |

| Dielectric Strengt | 500 VAC for 1 Minute |

| Max. Axial Load | 10N |

| Max. Radial Load | 25N (10mm from mounting Surface) |

| Certificates | Rohs, CE, CCC (As per Customer Need) |

3. Hybrid Stepper motor Performance Datasheet

| Model | Current A/Ø | Resistance Ω/Ø | Inductance mH/Ø | Holding Torque N.cm | Rotor Inertia g.cm2 | Lead # of Leads | Weight kg | Length mm | Matching Drive |

| 42AHS054-2004D-50-5F | 2.0 | 1.8 | 4.0 | 54.0 | 66 | 4 | 0.38 | 49.5 | Y2SD1R5 |

4. Mechanical Dimensions (in mm)

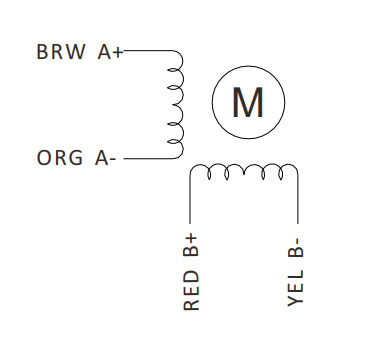

5. Wiring Diagram

6. Torque Speed Curves