Shenzhen Zion Kaifull Automation Technology Co., Ltd. |

|

Verified Suppliers

|

|

57HSS100-4004S-E1000AB Hybrid Step Servo Motor Nema23 1.0 N.m 4A 1000lines ABs Signal Encoder

1. Target Applications and Features

Kaifull, is one of the leading middle and high-end motion control products vendor in China with strong R&D capabilities and rich indutrial application experiences of products such as Steppers, Brushless, VFDs, Spindles, Planetary and Harmonic Reducers, Motion Controllers, etc.

Our HSM series stepper motors are widely applied in many innovative applications, including: electronics manufacturing equipments, 3D Printers, analytical and medical instruments, laser cutters, engravers,textile equipment, embroidery machine, precision positioning systems, packaging machinery, CNC machines and robotics etc.

We always work with you together to get your creative ideas or innovative products to go to market as fast as possible.

Compared with the traditional open loop stepper motor, the closed -loop step has the following advantages:

1. No step loss problem: Because the closed -loop step motor uses the encoder feedback control, it can correct the position deviation in real time, which will not lead to the phenomenon of throwing.

2. Higher speed and higher accuracy: Because the feedback system is used for control, the closed -loop step into the motor can achieve higher speed and higher accuracy.

3. Simple and easy -to -use: The control system of closed -loop step into the motor is relatively simple. Users only need to write the corresponding program to accurately control the motor

The working principle of the closed-loop step motor is similar to the open loop stepper motor. The key difference is that the closed-loop stepper motor is equipped with the encoder, which is to monitor the actual position of the motor rotor in real time, and feedback this information to the controller. The controller compares the actual and target positions, and then adjust the motor movement to ensure that it works as expected. This closed -loop control method makes the stepper motor more accurately.

The closed -loop step motor are widely used in many industrial applications:

Automobile manufacturing industry: engine parts and component production lines, mobilization production lines, vehicle assembly lines, body welding lines, detection equipment, etc.;

Machine tool manufacturing: lathe, dragon door planer, milling machine, grinding machine, mechanical processing center, dental machine, etc.;

Casting manufacturing: robotics, dumping furnace, mold processing center, etc.;

Pharmaceutical industry: raw materials processing machinery, preparation machinery, drinking machinery, printing and packaging machinery, etc.;

Electronic manufacturing: Printing circuit board (PCB) equipment, semiconductor device and equipment (optical engraved machine, wafer processor, etc.), LCD display (LCD) equipment, whole machine installation and surface paste (SMT) equipment, laser equipment ( Cutting machines, carvings, etc.), general CNC equipment, robotics, etc.;

Medical equipment: CT, X -ray machine, nuclear magnetic resonance MRI, etc.

2. Naming Rules and Main Specifications

| Number of Phase | 2 Phases, 4 wires |

| Step Angle | 1.8° |

| Step Angle Accuracy | 0.09° |

| Shaft Type | Single (customizable) |

| Ambient Temperature | -20 to 50℃ |

| Phase Current | 4A |

| Encoder Resolution | 4000counts per round |

| Encoder Type | Increamental, optical 1000lines, AB signals |

| Holding Torque | 1 N.m |

| Insulation Class | B(130°);Rise 80K Max |

| Weight | 0.8 kg |

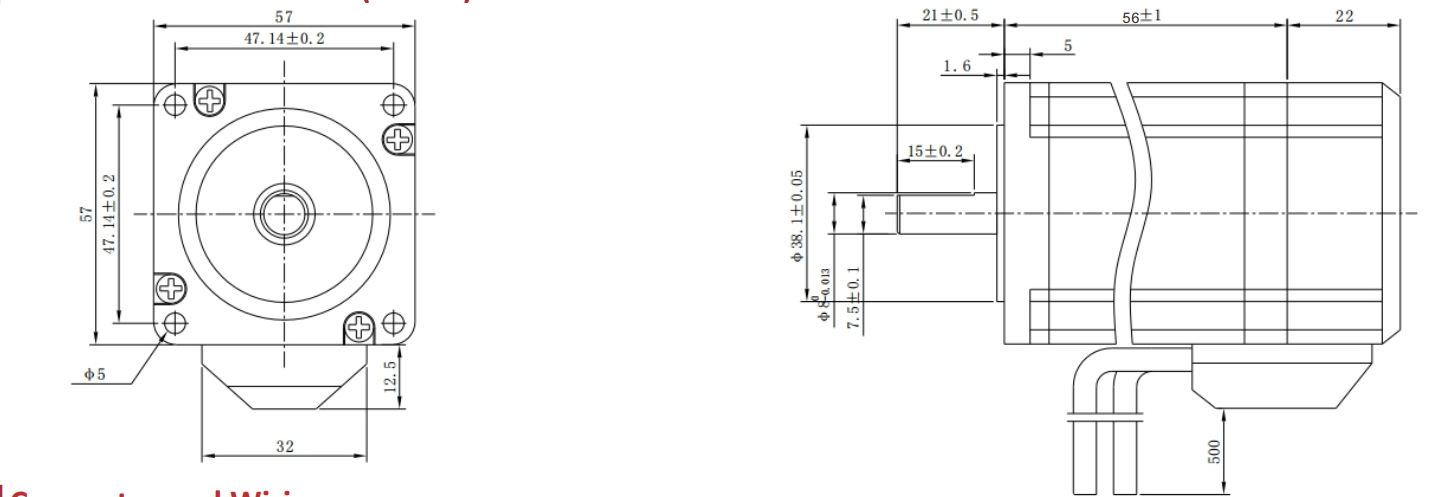

3. Mechanical Drawings (in mm) & Wirings

4. Torque & Speed Curves