Active Member

|

[China]

Address: No. 1 Damawan, Jiaodong, Jiaozhou, Qingdao, China/ Email: info@permixer.com

Contact name:

QINGDAO PERMIX MACHINERY CO., LTD |

|

Wear - Resistant Alloy Plates Planetary Concrete Mixer Environmental protection

Hydraulic System Maintenance Instruction

1. Strictly follow the instruction to check the condition of the pump before use if the hydraulic pump has stopped for a long time;

2. Replace the oil and oil filter after running the first 100hours, then replace the oil or oil filter after 1000 hours running. From then on, replace oil or oil filter every 2000 hours.

3. When replace oil, clean oil tank and working components with new oil firstly then pour new oil

4. Check the bolts regularly and assure they are not loosen ;

The performance characteristics of Mixer

1. Reasonable design and performance optimization of the whole machine

2. Convenient use and maintenance;

3. Firm and reliable, life factory;

4. Good mixing quality and high efficiency

5. Convenient operation and fast discharging speed

6. Low energy consumption and low noise

APPLICATION INDUSTRIES

1.Concrete

Precast concrete: various block bricks, sleepers, track slabs, metro tunnel segments, PC components, PCCP water pipe,

Lightweight aggregate concrete: Light soil cement slurry,polyphenylene granule cement slurry, other lightweight aggregate concrete,

High Performance ready-mixed concrete: Self-leveling mortar, etc.

2.Ceramics,

3.Pot Clay,

4.Glass Raw Material,

5.Refractories: Unshaped refractories, refractory bricks,

6.Casting materials: Sand mixing, casting coatings,

Others

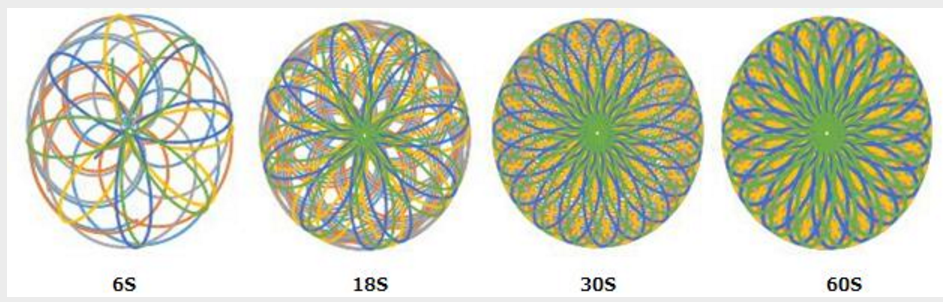

Principle of Motion: Mixing with no hidden corners in the mixing pan by installing mixing tools and scraper tools on a specially designed drive system. The mixing track as follows.

| Technical Data | ||||||||||||||

| PMC50 | PMC 100 | PMC 150 | PMC 250 | PMC 330 | PMC 500 | PMC 750 | PMC 1000 | PMC 1500 | PMC 2000 | PMC 2500 | PMC 3000 | PMC 4000 | PMC 4500 | |

| Output capacity(L) | 50 | 100 | 150 | 250 | 330 | 500 | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 4000 | 4500 |

| Input capacity(L) | 75 | 225 | 375 | 500 | 750 | 1125 | 1500 | 2250 | 3000 | 3750 | 4500 | 6000 | 6750 | |

| Input capacity(kg) | 120 | 360 | 600 | 800 | 1200 | 1800 | 2400 | 3600 | 4800 | 6000 | 7200 | 9600 | 10800 | |

| Diameter of Mixing Tank(mm) | 1300 | 1540 | 1900 | 2192 | 2496 | 2796 | 3100 | 3400 | 3400 | |||||

| Mixing Power kw | 3 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 55 | 75 | 90 | 110 | 160 | 200 |

| Blade QTY | 1/2 | 1*2 | 1*2 | 1*2 | 1*2 | 1*2 | 1*3 | 2*2 | 2*2 | 3*2 | 3/6 | 3/9 | 3/9 | 3/9 |

| Side Scraper QTY | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Bottom Scraper QTY | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 |

| Weight(kg) | 700 | 1000 | 1200 | 1700 | 2000 | 3500 | 6000 | 7000 | 8500 | 10500 | 11000 | 16000 | 18000 | |