ZHEJIANG TOP BEARINGS CO., LTD. |

|

Verified Suppliers

|

|

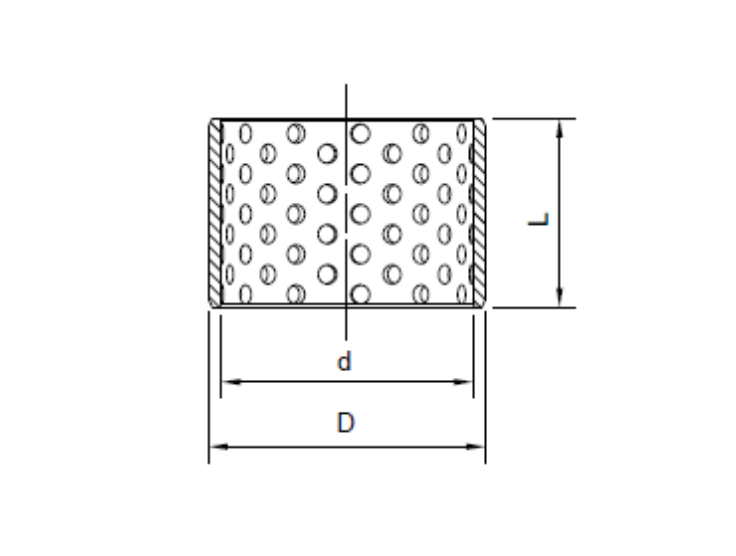

| ITEM | ID | OD | L |

| FB090 bronze bushing 30*34*30 | 30 | 34 | 30 |

| FB090 bronze bushing 40*44*40 | 40 | 44 | 40 |

| FB090 bronze bushing 50*55*40 | 50 | 55 | 40 |

| FB090 bronze bushing 50*55*50 | 50 | 55 | 50 |

| FB090 bronze bushing 50*55*60 | 50 | 55 | 60 |

| FB090 bronze bushing 60*65*40 | 60 | 65 | 40 |

| FB090 bronze bushing 60*65*50 | 60 | 65 | 50 |

| FB090 bronze bushing 60*65*60 | 60 | 65 | 60 |

| FB090 bronze bushing 70*75*50 | 70 | 75 | 50 |

| FB090 bronze bushing 80*85*60 | 80 | 85 | 60 |

| FB090 bronze bushing 90*95*60 | 90 | 95 | 60 |

| FB092 bronze bearings 40*44*40 | 40 | 44 | 40 |

| FB092 bronze bearings 40*44*50 | 40 | 44 | 50 |

| FB092 bronze bearings 50*55*50 | 50 | 55 | 50 |

| FB092 bronze bearings 50*55*60 | 50 | 55 | 60 |

| FB092 bronze bearings 60*65*50 | 60 | 65 | 50 |

| FB092 bronze bearings 60*65*60 | 60 | 65 | 60 |

| FB092 bronze bearings 75*80*60 | 75 | 80 | 60 |

With CusN6.5P0.1 or CusN8P0.3 bronze as the matrix, the bronze hole layout bearing is designed

with uniform and orderly oil filling holes. Lubricating oil is

injected after assembly. The bearing has the advantages of large oil storage, convenient installation, and small design machine, and can

replace the copper sleeve to use, greatly reducing the cost

The inner hole of the product is full of and oil pits, which can

store a large amount of oil during use and extend the refueling

interval.

2. Less oil lubrication, suitable for occasions where it is

difficult to add oil or water lubrication;

3. Good wear resistance, low friction coefficient, and long service life;

4. It can be used within the range of -100℃ to 200℃;

5. Good coupling performance, low noise, no pollution;

6. Thin-walled structure, lightweight, can reduce the mechanical volume;

7. The matrix has high density, gas-free shrinkage cavity, and large bearing capacity;

Currently has been widely applied to various mechanical sliding

parts, such as automation machinery and equipment (scale, swing,

slide, bending, cyclotron, turning parts) of the hydraulic cylinder

guide bush, textile machinery, plastic molding machine, die-casting

machine, rubber machinery, hydraulic truck, automobile, motorcycle

industry, ports, water conservancy, construction, agricultural

machinery, etc.

Wrapped bronze bearings are made entirely from phosphor bronze CuSn8. CuSn8 is characterized by the purity of the alloy with only a very low level of impurities. Wrapped bronze bearings are produced from strips that are subsequently wrapped and calibrated.

Wrapped bronze bearings must be lubricated with grease or oil on installation. A good quality lubricant is essential as it will reduce friction and wear by forming a film between the plain bearing and the shaft. For heavily contaminated applications, we recommend sealing off the bearing. This will protect both the bearing and the lubricant.

The main advantages of wrapped bronze bearings include:

Wrapped bronze bearings are especially suited to severe operating conditions where frequent maintenance is not possible. Common applications are:

Type | Thickness | Oil Depth |

| FB090 glidlager | 1mm | 0.3~0.4mm |

| 1.5mm | 0.4~0.5mm | |

| 2mm | 0.5~0.6mm | |

| 2.5mm | 0.6~0.7mm | |

FB09G glidlager FB08G glidlager | 0.65mm | 0.15~0.3mm |

| 1mm | 0.3~0.4mm | |

| 1.5mm | 0.4~0.5mm | |

| 2mm | 0.4~0.5mm | |

| 2.5mm | 0.4~0.5mm |