ZHEJIANG TOP BEARINGS CO., LTD. |

|

Verified Suppliers

|

|

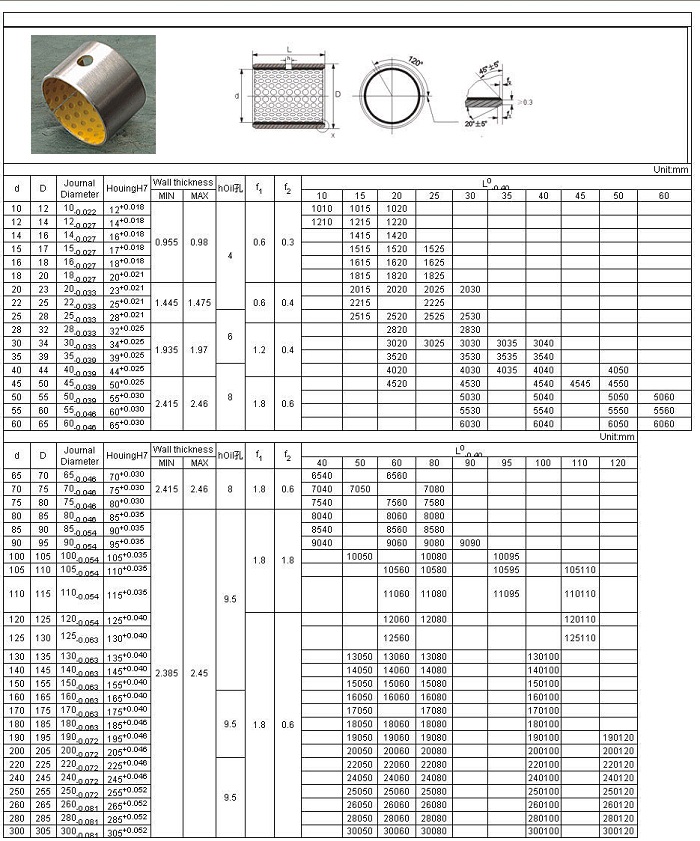

POM Boundary Lubricating Bearings Low Carbon Steel + Porous Bronze + Yellow POM

It is designed for marginal lubricating bearing, backed with copper-plated steel with porous bronze sintered on it and polymers (POM) imbedded into the bores of the bronze. The steel back provides the products with stronger mechanic strength and load capability. Oil dents stamped on the surface of the polymer can achieve good lubrication between the bearing and its mating axis. It is good of anti-abrasion and load capability. The plating coating on the surface is erosion protective. And it is environment protective as no lead includes in the surface polymer POM. This series are widely used on automotive chassis, forging machines, mine quarrying machines, metal melting and casing machines and in water irrigating and steel rolling industries, etc.

Physical and Mechanical Performance

| Performance Index | Data | Performance Index | Data | ||

| Max. Load | Static Load | 250N/mm² | Friction Coefficient | Grease Lubrication | 0.15~0.25 |

| Dynamic Load | 140N/mm² | Oil Lubrication | 0.05~0.15 | ||

| Oscillation Load | 70N/mm² | Mating Axis | Hardness | >270 HB | |

| Linear Velocity | Grease Lubrication | 2.5 m/s | Roughness | Ra=0.4~1.25 | |

| Oil Lubrication | >3 m/s | Working Temperature | -40~+120℃ | ||

| Max. PV value | Grease Lubrication | 2.8 N/mm²·m/s | Heat-conducting Coefficient | 52 W/(m*k) | |

| Oil Lubrication | 50 N/mm²·m/s | Heat-expansion Coefficient (Axial) | 11*10^-6k | ||

Physical and Mechanical Performance

Normally, the surface polymer is chemical-erosion resistant quality. So its erosion-prevention quality is primarily decided by the quality of the steel back and its plating layer. Air-erosion could be effectively prevented if the steel back is bronze or tin-plated. If the bush is to be used in erosive environment, the steel back needs to be plated with zinc, nickel or nickel-chrome ally, etc.