|

|

[China]

Trade Verify

Address: Room 401,Unit 1,Building 6,Kecheng Kechuang Yuan,No.1500 Wenyi Xi Road,Cangqian Street,Yuhang Area,Hangzhou City,Zhejiang Province,China

Contact name:Wei

Hangzhou SED Pharmaceutical Machinery Co.,Ltd. |

|

Verified Suppliers

|

|

Cosmetic Ointment Manufacturing Machine For Cream Shampoo Production

Product Parameters of Ointment Manufacturing Machine

| Capacity | Design volume: 250L, working capacity:200 L | ||

| Kettle Cover | Liquid(particle)inlet, sunk material inlet, air inlet with filter, inspect light and sight glass, vacuum port, pressure meter(1 to -0.1 bar), pressure clamp | ||

| Mixing pot | Material | Inner layer: SUS316L thickness: 3mm | |

| Middle layer: SUS304 thickness: 2mm | |||

| Outside layer: SUS304 thickness:2mm | |||

| configuration | Bottom material exhaust, size: 1.5” | ||

| Temp. sensor (0-199℃) | |||

| Electrical heating: 18kw, cooling water inlet | |||

| Stirring system | Homogenization | 1.Material: SUS316L; standard homogenizer 2. Power: 4kw/380/50Hz; RPM: 2800R/Min | |

| Stirring scrap and middle stirring | Material: SUS316L,Scrap material: PTFE | ||

1. Stirring scrap and middle stirring use the same motor 2,Power:2.2kw/380V/50Hz;RPM:21~118r/min(Frequency control) 3. Stirring scrap and middle stirring rotating the opposite direction | |||

| Safety: 1. During stirring, the cover can not open, 2. Cover lift can not stirring. | |||

| Vacuum system | 1. Vacuum pump: water recycle, power 2.2kw/380V/50Hz 2. With pressure sensor (during vacuum condition, hydraulic can not open) | ||

| Heating method | Jacket electrical heating | ||

| Exhaust method | Electric doom and bottom discharge or positive pressure discharge material | ||

| Pressure | Pressure in the pot during working: -0.090 Mpa; Jacket working pressure:0.2 Mpa | ||

| Control box | SUS304 , 1.2mm thickness | ||

| Dimension | 3500mm×2450mm×2250 mm | ||

| Shelf is SS, platform with raised platform and SS guardrail | |||

Working principle of Ointment Manufacturing Machine

The SED-200RZ main pot is composed of the cut-off mixing pot, cut-off mixer unit, circulating system and the stirring system etc.The materials are sucked into emulsifying pot by transportation pipe under the vacuum state, or it also can be put from the feed inlet.

Feature of Ointment Manufacturing Machine

1. The ultra-high viscosity emulsion shall be fully and evenly

stirred.

2. Vacuum suction, high production frequency and operation

frequency, simple and reliable operation.

3. It can be used for heating, melting, vacuum, homogeneous cooling

and consistent operation.

4. It is made of stainless steel, and the vacuum stirring is

sanitary, sterile, and easy to clean.

5. The newly developed ceramic gapless high shear homogenizing

emulsifier.

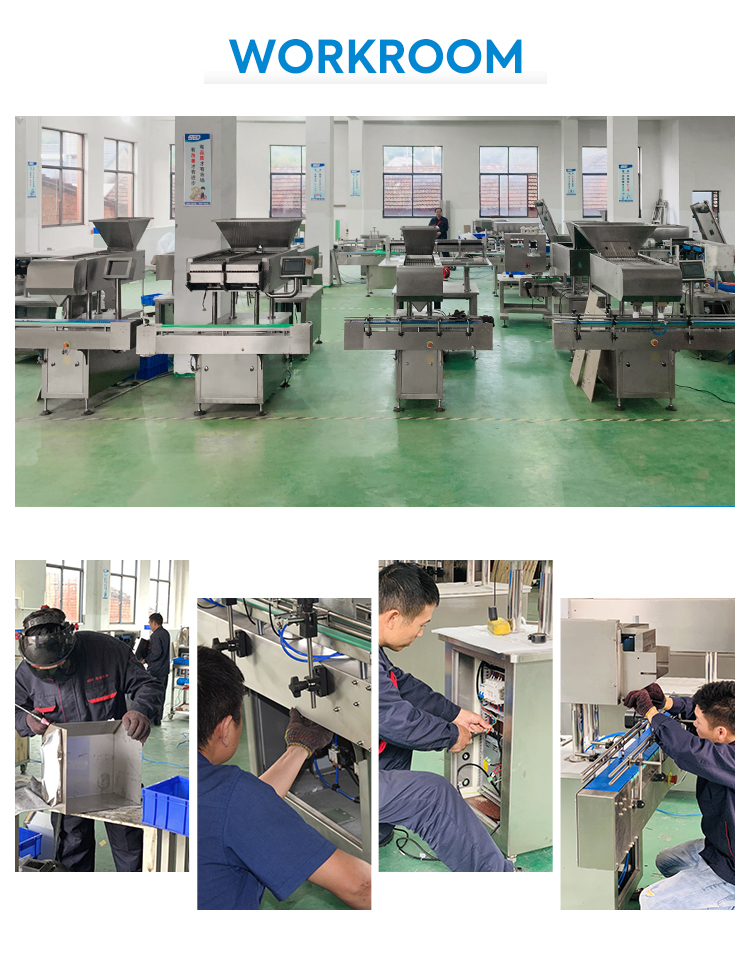

Show of Ointment Manufacturing Machine