Zhangjiagang Eceng Machinery Co., Ltd. |

|

Verified Suppliers

|

|

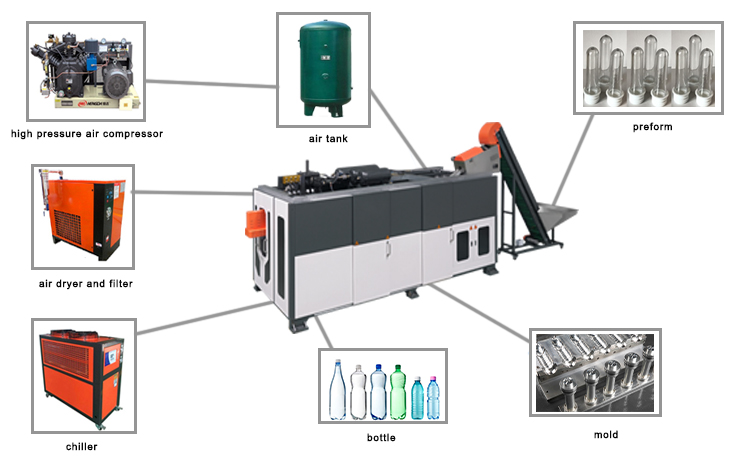

200 300 500 750ml bottle water plastic pet blowing machine machine

Eceng K series stretch blow moulding machine adopt 6servo motors.

Main chain system, stretch system, 2pcs servo motors for clamping

mould system, Variable pitch system, preform feeding and bottle

taking system.

Eceng K12 is fully automatic PET bottle blowing machine, bottle

making machine up to 750ml for small bottles. The machine is fully

automatic, efficient and stable, requires minimal human

intervention, and can produce a large number of bottles in a very

short time. Production capacity is as high as 22000~26000BPH. Can

be widely used in food, beverage, cosmetics, pharmaceuticals and

other industries of small bottle production. In addition to high

efficiency, in the production facilities also relatively small, and

easy to operate and maintain, suitable for large and medium-sized

enterprises.

Main Features

1.stable and accurate running at high speed,adopt more stable and advanced microcomputer PLC control system.

2. production process is fully automated, with the advantages of low investment, high efficiency, easy operation, simple maintenance and safety.

3. servo transmission system, high positioning accuracy, fast speed, good stability and reliability.

4. suitable for flexible production of small quantity and various bottle shape,wide range of applications,meet customer needs.

5. increase energy using efficiency,increase productivity per unit of time.

6. manual and automatic methods of operation, human-machine interface control, simple operation.

7. servo transmission system, high positioning accuracy, fast speed stability and good reliability.

8. safety self-locking device in each mechanical action,when a certain process fails, the program will automatically switch to a safe state.

9. heat and noise are significantly reduced compared with YCQ series.

10. less than 0.2% scrap rate for finished bottle .

Product Parameters

| Model K12 | ||

Bottle type specification

| Cavity | 12 |

| Max.volume | 200ml-750ml | |

| Bottle mouth maximum overall diameter | 25-29mm NECK | |

| Bottle biggest diameter | 75mm | |

| Bottle maximum height | 180mm | |

Capacity specification

| Theory output | 22000~26000BPH |

| Bottle type volume | 600ML | |

| Bottle type weight | 13.5g | |

| Bottle type | Round | |

| Power specification | Light tube quantity | 32pcs |

| Light tube power | 1.75KW | |

| Maximum heating power | 56KW | |

| All electric machine installation | 71KW | |

| Actual consumption | 30%--60% | |

Air pressure specification

| Work pressure | 5-6kg/cm2 |

| Blow bottle pressure | 25-45kg/cm2 | |

| Higher -pressure gas consumption | 24000Ltr/min | |

| Forzen water specification | Work pressure | 5-6 kg/cm2 |

| Temperature range | 10℃ | |

| Consumption | 12000kcal/hr | |

| Temperature range | 10℃ | |

| Forzen water flow | 180L/min | |

| Machine specification | Machine size | 9.0x2.0x2.3 |

| Machine weight | 10.0ton | |

1, Auto-loader improves working efficiency,accurate

transportation,reliable and durable,raw materials are completely

free of moisture,pollution,foreign matter, and loss during feeding

process.Realize transportation process of feeding process, avoid

danger of high-altitude feeding, reduce labor intensity and

increase production efficiency.

2, New clamping system,upgraded on the basis of the original

ones,increase mould clamping speed and output,greatly reduce mold

clamping noise.

3, Adopt infrared lamp heating, strong penetration, preform

rotation heating, track revolution, heating evenly, fast and

reliable; heating lamp,reflector width and height can be adjusted

to suit preform heating of different structure,with automatic

temperature-removal device to ensure the constant temperature of

oven.

4, k series bottle blowing machine adopts advanced microcomputer

PLC control system, stable performance; servo transmission system,

high positioning accuracy, fast speed, stable and reliable.

Want to know more message , contact us with out hesitate ! Send us now !

——Transport&Payment——