Dongguan Chuangwei Electronic Equipment Manufactory |

|

Verified Suppliers

|

|

PCB Depaneling Router Machines with CCD Camera Alignment & CNC Programming

1. Machine Parts List

I. Hardware |

|

SPINDLE | Morning Star spindle and inverter |

CCD | Sony 520 line industrial cameras |

LENS | Computar EX2C |

Screw | TBI Precision ground ball screw imports |

Guide | HIWIN widening Imported linear guide rail |

MOTOR | JiaBao LCF Series |

I/O CONTRONL CARD | HFC PCI-9074 |

DRIVER CONTRONL CARD | HFC PCI-9074 |

I/O CARD | PCI-9074-64pcs/-38pcs |

Static cleanup | STATIC-ST401A Series |

Computer | RMC-8401/6113LP4/300ATX/8651VNA/P4 2.8G 2CPU(S)/1G DDR/80G) |

Machine interface | AOC LCD17",Logitech mouse |

2. software |

|

Control system | Windows XP Professional (Service3,v.3244) |

Operation GUI | Chinese Windows XP |

Program edit | Inline |

Vision system | CCD AOTU offset |

Control system | F 1.0.2 version |

2. Performance Parameters

Overall |

|

Dimensions(W*D*H) | 1220mm*1450mm*1420mm |

Weight | 550KG |

Height offset | 60~110mm |

Manipulator |

|

Motor type | JiaBao series |

Positioning repeatability | 0.001mm |

Axis working area(max) | 680mm*360mm*50mm |

Work station |

|

PCB fixation | standard,specialization |

PCB loading/unloading | manual |

PCB size (max) | 322mm*322mm |

PCB thick (max) | 5mm |

Fixturing |

|

Rigidity fixturing | standard |

Fixturing fixation | machinery |

Spindle Motor |

|

Power | 400W |

Spindle | 50000rpm/min |

Protect | self/wind cooling |

Change cutter | Specialization |

Routing capability |

|

Cutting speed(max.) | 100mm/s |

Driving speed(max.) | 3000mm/s |

Precision of cutting | 0.01mm |

Vacuum System |

|

Vacuum power | 2.2KW AC 380V |

Vacuum | plumb |

Utilities |

|

Power | 2.2KW AC380V |

Air supply | 2~5KG/cm2 |

Programming |

|

Program edit | Inline |

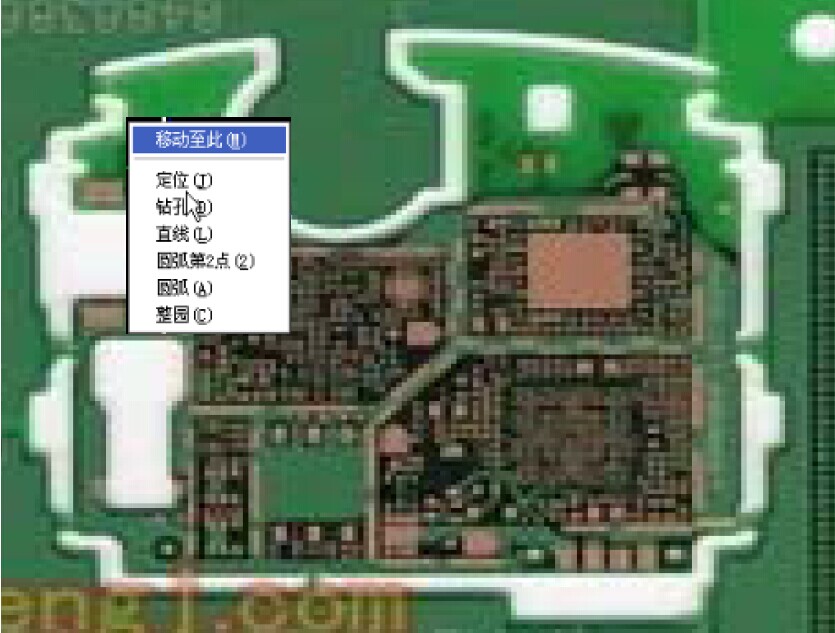

Function edit | Line,arc,circula,U-curve |

Program storage | HDD |

Vision system | SONE colour CCD |

milling cutter offset | AUTO |

Vacuum setup | AUTO |

Operation Monitors |

|

Iindicator | Iindicator Machine state |

tool check | Automatic detection tool life, the use of time testing |

Motor protect | Have overheating, overload, low voltage protection function |

motor over loading check | Have Overload, the line is normal, low voltage protection function |

Tool usable time | Automatic detection tool life, |

Data statistic | Separate board model, separating count, diverse counting methods |

Error record | Software automatically records all alarms memory of machines |

III. Accuracy |

|

Axis precision | 0.001mm |

Cutting precision | 0.1mm |

IV. Safety |

|

Working area protect | With four sealed protection |

Door sensor | Front and rear safety door micro-switch sensor (optional) |

Exigency stop button |

|

3. Function Description

1) X10 zoom-in image makes programming easier&increase the accuracy of point setting

2) Two sliding table provides simultaneously in-and-out movement to reduce the tack time for better productivity.

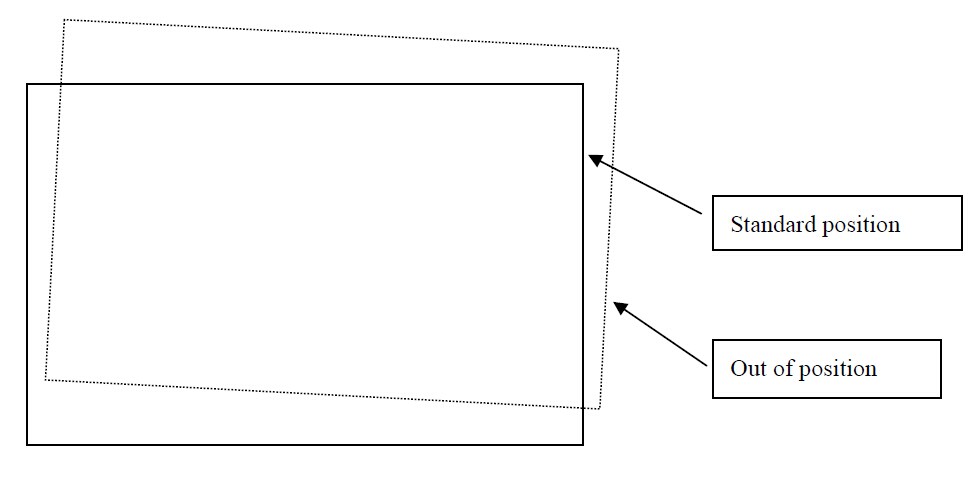

3) AUTO MARK offset system.CCD image could check&simulate the path or routing to reduce unnecessary mistake before cutting

4) Routng bit automatically lift and shift to next programmed point then cutting to extend the life time of routing bit .

5) Safety door industry design

6) CCD image could check&simulate the path or routing to reduce unnecessary mistake before cutting

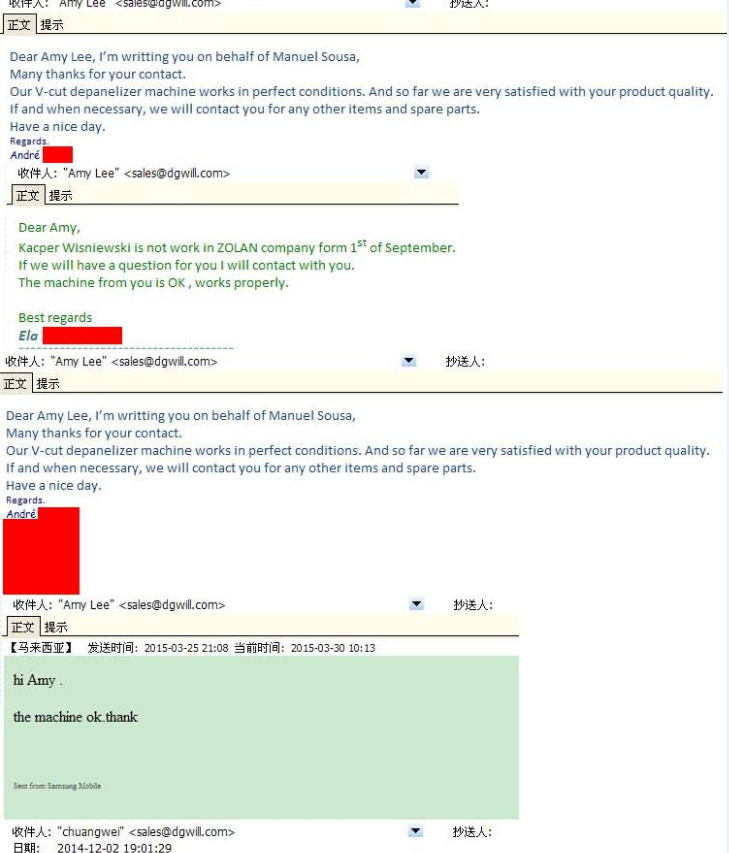

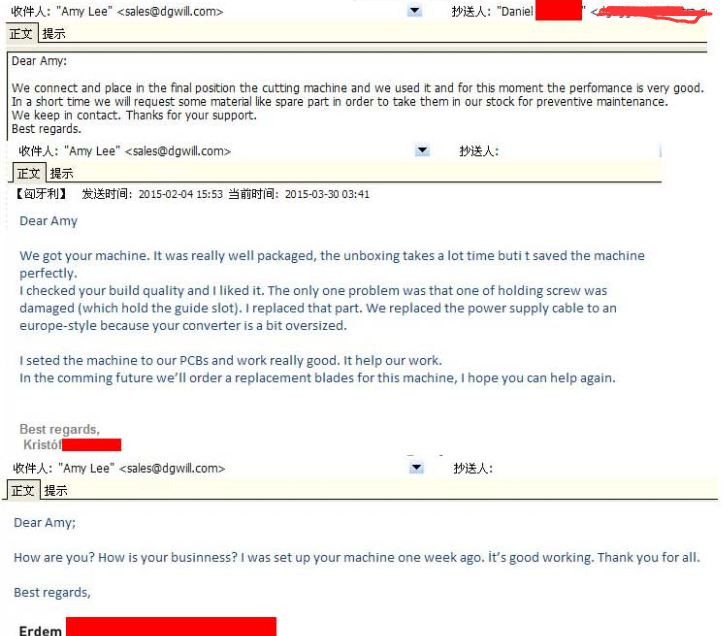

Customers comments

Our best service

1. One year warranty for the machines except accessories.

Robust frame construction and Japanese steel blades obtained good appraise and recognized by and oversea clients. We offer parts for replacement under warranty free of charge, clients only need to bear freight charge.

2. Engineers available to service machinery oversea.

Engineers are available to be sent to freign countries to do machinery training and offer technical support.

3..Mature technique & forerunner to process makes high quality machinery.

As largest manufactory in South China, we have 12 years experience on PCB separator machines and soldering machines. pcb router machine

Our R&D team continuously upgrade the existing machines to meet the market development trend

4. Effective customer service.

All of us together are stronger and wiser than any one of us individually. To succeed, we must assume responsibility, cooperate with fellow associates and withdepartments, effectively comminicate with one another, foster enthusiam and participate in decision-making. To be seay reachable by customers and provide prompt replies to solve their problems and create value for customers

About us

Dongguan ChuangWei Electronic Equipment Manufactory was founded in 2004,is located in the world manufacturing city Dongguan,Guangdong,China. The company is committed to development,manufacture,sales and service for professional pcb separator/pcb depanelizer electronic equipment machinery. The company has advanced production and processing equipment and an experienced development and manufacture team, half of them have over 10 years experience in electronic equipment industry. |

Begin with 2004 the company leader invested to develop and manufacture the PCB separator and PCB depaneling machine. From then on we pay more attention to product quality, safe to use and product innovation, so far we have produced many high quality, stable performance, high cost-effective products. Improve production yields, increase productivity, and thus enhance the market competitiveness of our customers. |

Until now we have design different separating PCB types of PCB separator and PCB depaneling machine with manual, motor-driven, pneumatic-driven, mold punching, milling cutter router. Due to the good quality and reasonable price our customers are all over the world. Up to now ChuangWei have became one of the biggest PCB separator production base in China |

Company always insists to the "customer needs is our goal, creating most value for customers", strives to provide customers with first-class products, first-class service. So since date established we very attached importance to product quality,continuous improvement for manufacturing process,try hard to save money for customers.

|

Our great mission is to be the most professional and excellent supplier in the pcb separator/pcb depanelizer electronic equipment industry. |

Cooperative partners from different electronics industry

More information welcome to contact us:

Email: s5@smtfly.com

Wechat/Whatsapp:+8613684904990