Dongguan Chuangwei Electronic Equipment Manufactory |

|

Verified Suppliers

|

|

Solder Pallet SMT Process Carriers with Durostone Material Tin

Furnace Fixture

Description

Pallet solutions for reflow and wave soldering Process.

Open as well Selective Soldering pallet.

Wave Soldering Pallet designing and manufacturing with well

design experts team. We are well established and process

expertise , by which we are able to maintain our self to

provide a right solutions for our customers.

Right now we are providing good Soldering

Process solutions through wave soldering pallets which

are not only giving good results as Process

concerns but also effective process setup.

Designed by engineers with extensive wave solder experience, our

pallets enable customers to automate the soldering of through-hole

components on complex electronic assemblies.

The pallets only expose areas of the assembly that require

soldering. All other areas are protected, eliminating component

damage and expensive, low quality process steps. Made of ESD-safe

composite materials, these pallets are designed and manufactured to

optimize both the solderability of your circuit boards and your

entire process flow.

【Features】

1. Eliminate hand soldering processes

2. Eliminate high-defect, surface mount glue operations

3. Eliminate temporary solder masking operations

4. Reduce assembly cycle time,Improves Quality, Improve component

alignment and soldering

5. Improved solder fill and quality

6. Eliminates flooding problems , Increases your flexibility,

7. Eliminates board size / panelization issues

8. Standardize on conveyor width

9. Effectively process complex, double-sided surface mount

assemblies,Easy to Use

10. Designed by engineers with extensive wave solder experience

11. Optimized for easy profiling

12. Supports rapid set-up using our ergonomically designed

fasteners

13. Optimized for best soldering

14. wave solder automation to solder through-hole components on

complex electronic assemblies.

15. Optimize the use of your wave solder equipment, eliminate

unreliable surface mount gluing operations, and Wave Solder Pallets

protect backside areas of your circuit board assembly while

directing solder to components that you want wave soldered. Made of

ESD-safe composite materials, these pallets are designed and

manufactured to optimize both the solderability of your circuit

boards and your entire process flow.

1. Engineers available to service machinery oversea. |

2. Mature technique & forerunner to process makes high quality

machinery. |

3. One year warranty for the machines except accessories. |

4. Effective customer service. |

Our mission |

Our Vision: |

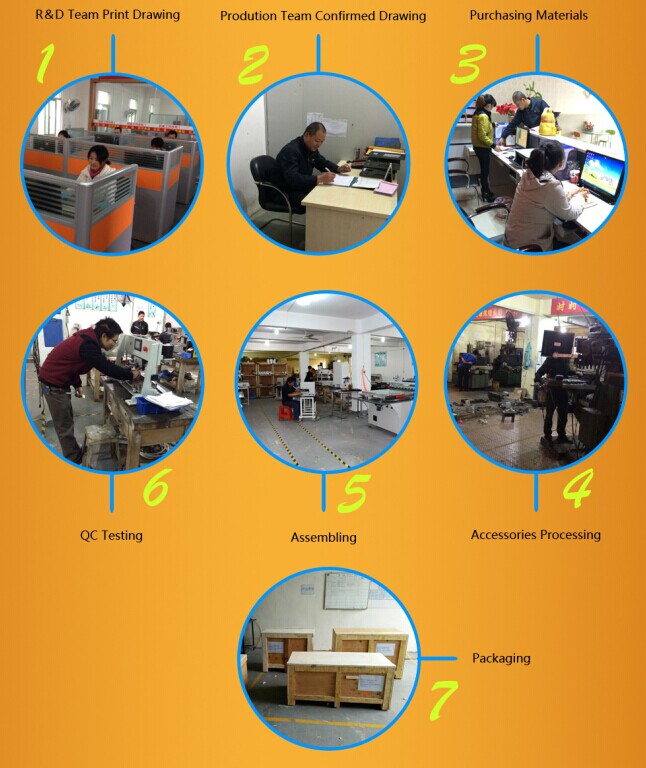

Our production flow

CE approval

More information welcome to contact us:

Email/Skype: s5@smtfly.com

Mobile/Wechat/WhatsApp: +86-136-8490-4990