Dongguan Chuangwei Electronic Equipment Manufactory |

|

Verified Suppliers

|

|

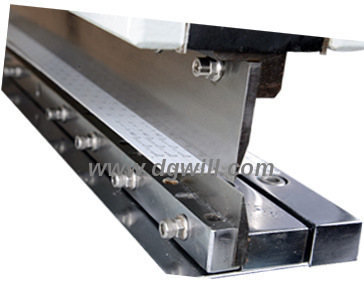

Pcb Separator For Electronics Industry With Linear Blades CWVC-450

V CUT PCB Separator machine

1 . Easy maintenance and operation

2 . Thin PCB even to 0.3mm can be depaneled safely

3 . Depaneling process without vibrations due to pneumatic drive

unit

V-CUT PCB Separator machine specifications

| Model | CWVC-450 |

| Max. PCB depaneling length | 450mm(Can custom made) |

| PCB depaneling thickness | 0.3-3.5mm |

| Voltage and Power | 110V/220V -- 10W |

| PCB depaneling speed | due to operator skilled level |

| working air pressure | 0.5-0.7Mpa |

| PCB depanelizer machine size | 620*230*400mm |

| PCB depanelizer machine weight | 165kg |

V-CUT PCB Separator machine fetures

1 . Pneumatically driven and electromagnetic valve control .

2 . Depaneling process without vibrations due to pneumatic drive

unit .

3 . Depaneling PCBs with sensitive SMD, capacitors or thin board

even to 0.3 mm can be depaneled safely .

4 . Depaneling operation is that operator stamps the foot pedal to

Depanel PCB .

5 . Highest components near the v groove of PCB can be up to 70mm

.

6 . The minimum distance is allowed to be 0.5mm between V

groove and the electronic components .

7 . Gap for insertion of PCB can be easy to adjust by the adjusting

knob in front of the machine .

Our Competitive Advantage :

Pneumatically driven and electric control

The machine is pneumatically driven and electric control . The

straight knife type separator machines were designed to separate

pre-scored panel boards carefully , without bending or tension

stress . Even

sensitive SMD-components like ceramic capacitors will not be

damaged by the separate process . Due to the special design of the

knives also boards with high components placed close to the edges

can be separated safely . Based on a proven method of separating,

wedge-shaped knives are used to cut the panels within the groove .

This enables boards of less than 1 mm thickness to be separated

safely and without creating stress .

V-CUT PCB Separator machine operation video please see below:

http://www.youtube.com/watch?v=zuFZH9KcxZs

http://www.youtube.com/watch?v=PWOYDPsJiUY

http://v.youku.com/v_show/id_XNTk2NzgxNDEy.html

http://v.youku.com/v_show/id_XNTk2NzU4NzA4.htm