Shenzhen Hansome Technology Co., Ltd. |

|

Verified Suppliers

|

|

| Model | HS-SL7331S | |

| Production name | 6Axis Automatic Screw Locking Machine | |

| Moving range(X1/Y1/Z1) | 300*300*100mm | |

| Moving range(X2/Y2/Z2) | 300*300*100mm | |

| X/Y axis moving speed | Closed loop motor :1-800mm/s | |

| Z axis moving speed | Closed loop motor: 1-300mm/s | |

| X/Y axis max load | Closed loop motor: 5KG | |

| Z axis max load | Closed loop motor: 3KG | |

| Power supply | AC110V/220V, 50/60Hz | |

| Repeat accuracy | ±0.02mm | |

| Document support | CAD CorelDraw | |

| Suitable screws | M1-M6 | |

| Machine dimension | 1092*585*800mm | |

| Machine weight | 85kg | |

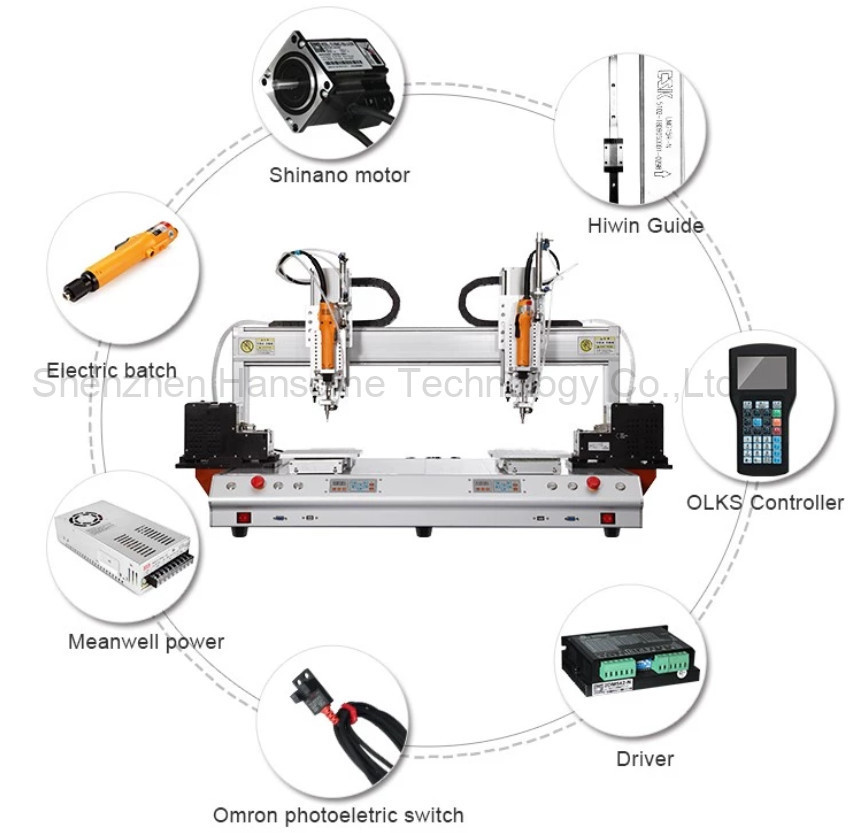

Features

Main parts brand

1, Motor: Shinano

2, Guide: Hiwin

3, Photoelectric switch: Omron

4, Power supply: Meanwell

About Packaging