Modular Design Variable Speed Control PCB Reject Conveyor

Introduce:

This unit provide the OK and NG board selection function on the smt

production line. It can be used when visual inspection of PCBs

required. PCBs will continue to run, thus without interrupting the

normal PCBs flow.

Features:

1. Reject, inspect and by-pass modes all available.

2. Modular design.

3. Stability enhanced by robust design.

4. Laser carved stainless steel side guide for superior

quality and durability.

5. Ergonomic design arm rest.

6. Smooth and parallel width adjustment(lead screw).

7. Different lengths available upon request.

8. Variable speed control.

9.SMEMA compatible.

Key Features

Dedicated Pathway:

- Designed to create a separate pathway for rejected PCBs, ensuring

they are efficiently removed from the main line without disrupting

the flow of good boards.

Automatic Detection:

- Often integrated with automated inspection systems (e.g., AOI -

Automated Optical Inspection) that can identify defective boards

and trigger the reject mechanism.

Flexible Design:

- Can be configured in various layouts to fit the specific

requirements of the manufacturing facility, including different

angles and lengths.

Durability:

- Built with robust materials to handle the demands of a

manufacturing environment, ensuring long-lasting performance.

Speed Control:

- Many models offer adjustable speed settings to synchronize with the

main conveyor system and maintain an efficient workflow.

Safety Features:

- Equipped with safety mechanisms, such as emergency stop buttons and

guards, to protect operators and ensure safe operation.

Applications

Quality Control:

- Primarily used in quality control processes to remove defective

PCBs after inspection, preventing them from proceeding to assembly

or shipping.

Repair Stations:

- Transport rejected boards to designated areas for troubleshooting,

rework, or repair, facilitating efficient handling of faulty

products.

Waste Management:

- Can be used to transport boards marked for disposal, ensuring

proper handling and processing of electronic waste.

Prototyping and Testing:

- Useful in environments where prototypes are frequently tested,

allowing quick removal of non-functional boards.

Benefits

- Improved Quality Assurance: Ensures that only quality PCBs continue through the production

process, reducing the chances of defects in final products.

- Increased Efficiency: Automates the removal of rejected boards, allowing for quicker

responses to quality issues and minimizing manual handling.

- Streamlined Workflow: Keeps the production line organized by separating defective

boards, which helps maintain a smooth flow of good products.

- Cost Savings: Reduces the costs associated with defective boards reaching the

market and improves overall product reliability.

Considerations When Choosing a PCB Reject Conveyor

- Compatibility: Ensure the reject conveyor integrates seamlessly with existing

inspection systems and conveyor layouts.

- Capacity: Choose a system that can handle the volume of rejected boards

expected in your production environment.

- Flexibility: Look for conveyors that can be adjusted or reconfigured as

production needs change.

- Ease of Maintenance: Consider models that are easy to maintain and have readily

available replacement parts to ensure long-term reliability.

- Safety Features: Ensure the conveyor includes necessary safety features to protect

operators and equipment.

Specification:

| Model | HS-CVN350 | HS-CVN460 |

| Efficient PCB length | 50*50~450*350mm | 50*50~550*460mm |

| Machine dimension | 1000*690*930mm | 1000*800*930mm |

| Weight | 70kg | 90kg |

| Transport height | 910±20mm |

| Transportation direction | L~R, or R~L(optional) |

| Transporting speed | 0.5~20 m/min or specify |

| Power supply | AC100-230V,50/60Hz,single phase |

| Power consumption | 100VA max |

| Air pressure | 4-6bar |

| Air consumption | Max 10L/min |

| Communication | SMEMA |

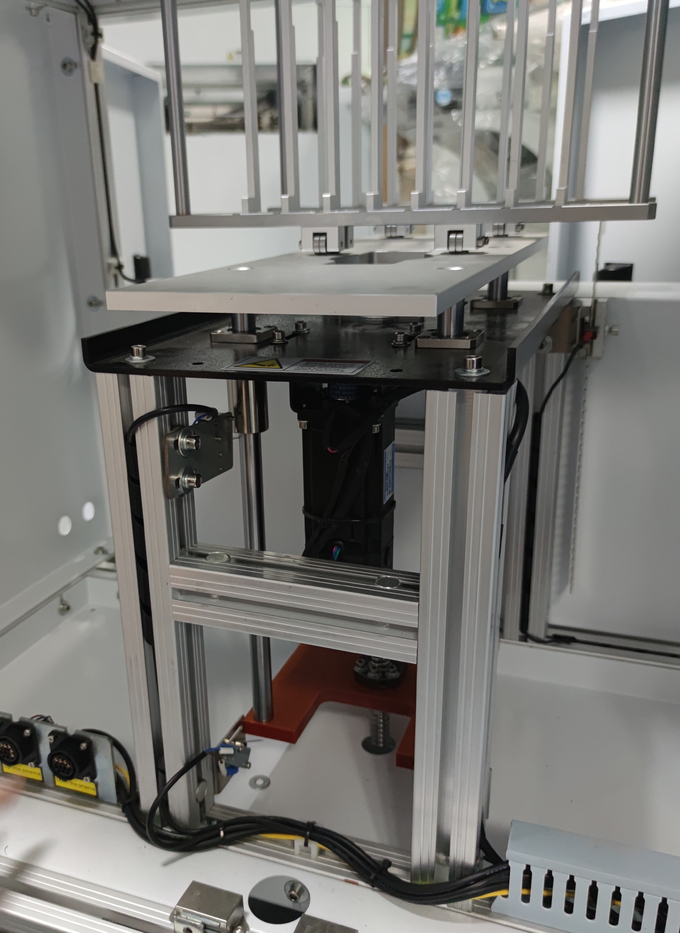

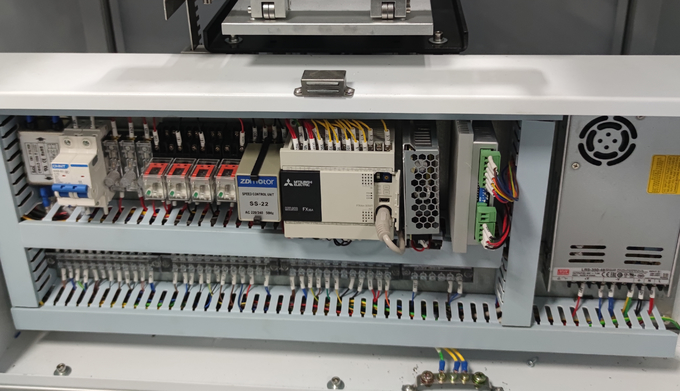

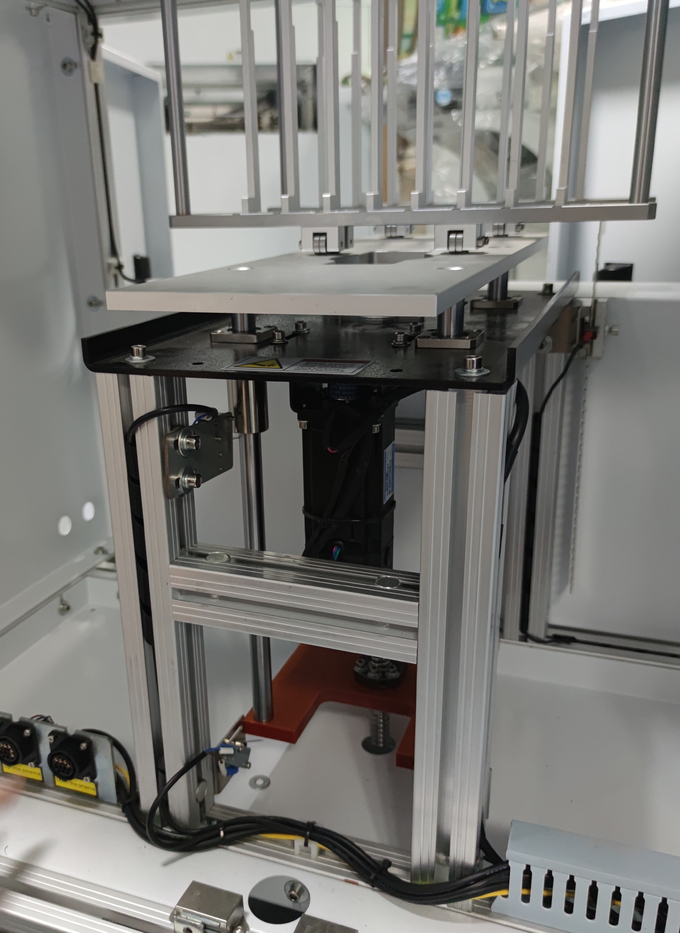

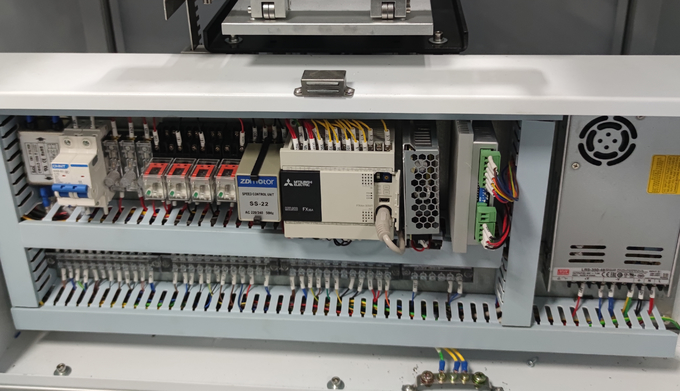

product details: