|

|

[China]

Trade Verify

Address: 3rd Floor,Building A,Sha Tang Bei Fang Yong Fa Industrial Area,Sha Jing, Bao an, Shenzhen, China

Contact name:Rudi Jin

Shenzhen Hansome Technology Co., Ltd. |

|

Verified Suppliers

|

|

Manual Programming Double Soldering Tip Robotic Soldering Machine

Introduction:

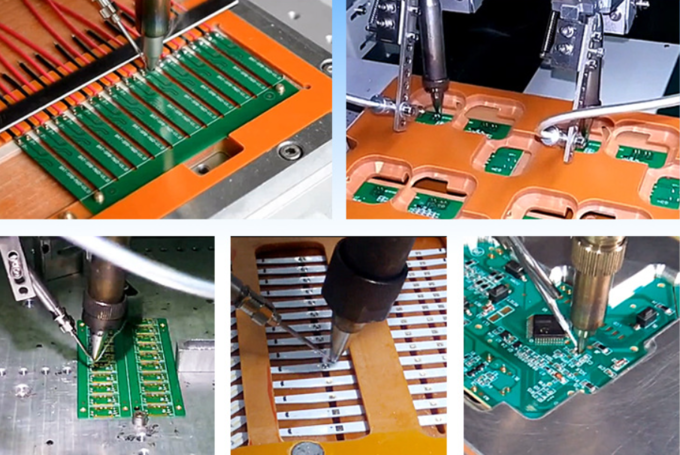

Automatic benchtop soldering machine, it used for instead of the traditional manual soldering. By make customized fixtures to fix the products, the temperature controller heating the solder tip, solder wire automatic feeding, the machine will automatic soldering the products according to the setted programs.

Features:

1, Stable structure, high precision soldering.

2, Benchtop/Desktop type, easy to moving and maintenance.

3, Use each box to set the programs, programs can storage and import directly.

4, The soldering tip/iron available for 360degree rotation.

5, Traveling distance 500*300*300*100mm.

6, Automatic solder wire feeding.

7, Available for spot, drag, circle, curve and other inregular soldering pcb panels.

8, Double soldering tip, double working station, high efficiency in circular working, keep the machine working all the time.

9, Precision tin vol control&consistency welding, can save at least 30% tin volume compared with manual soldering.

10, High quality heating and temperature controller, temp accuracy at ±2℃.

11, Smoke purification filter system, extend the lifespan of the solder iron, improve the soldering quality.

12, The machine with automatic cleaning function, which can make the solder processing more stable, and extend the lifespan of the solderin iron.

Specification:

| Model | HS-S5331R |

| Voltage | AC110V/220V,50/60Hz |

| X/Y1/Y2/Z working range | 500*300*300*100mm |

| R axis | 360 degree |

| Materials | High end aluminum |

| Solder wire diameter | 0.6~1.0mm |

| X/Y1/Y2/Z moving speed | max 300mm/s |

| Driven system | Stepper motor,timing belt |

| Linear guide | Taiwan brand high precison guide |

| Repeat accuracy | ±0.02mm |

| Programing | Manual programmin with teach pendant |

| Control system | Control board |

| Program storage | It can store one thousand sets of processing data and a single processing file can occupy up to 3M storage space (five thousand processing points) |

| File storage space | Handheld box 256M, offline card 32M, single processing file up to 3M storage space (100,000 processing points) |

| Document support | CAD/dwg format |

| Iron Tin cleaning | Air cleaning/pneumatic |

| External interface | USB+RS232 |

| Soldering method | Point/drag soldering |

| Weight | 85kg |

| Machine dimension | 680*585*800mm |

Application:

The automatic soldering machine is mostly used in the electronics manufacturing industry. It is mainly used for process processes and solder processing that are difficult to achieve in reflow soldering and wave soldering.

It is especially suitable for mixed circuit boards, heat sensitive components, and sensitive devices in the SMT back-end process. Welding, widely used in PCB board welding line, charger plug welding, connector soldering, DC end tin, LED light strip connection and other fields.

Automatic soldering robots replace manual soldering to improve work efficiency and improve solder quality.Suitable for automotive electronics, digital, electronic products, LCD, circuit board and other production industries, connectors, RJ / network transformers, cable, FPCB welding, COF welding, computer motherboards, CABLE, speakers and motors Quality welding industry.

About Packaging