YUSH Electronic Technology Co.,Ltd |

|

Verified Suppliers

|

|

| U series reflow oven main specifications | |||

| Model No | YSL-808UA/YSL-808UN | YSL-810UA/YSL-810UN | YSL-812UA/YSL-812UN |

| Heating System | |||

| Heating Zone | 8 heating zones,16 heating modules | 10 heating zones,20 heating modules | 12 heating zones,24 heating modules |

| Heating Length | 2950mm | 3670mm | 4390mm |

| Cooling Type | Three cooling zones:forced air cooling/water cooling | ||

| Outlet Exhaust Diameter,valume | 2-φ145,Exhaust demand 15-20m³/min*2 | ||

| Conveyor System | |||

| Product Width | min50mm-max400mm | ||

| Conveying Direction | L→R,R→L | ||

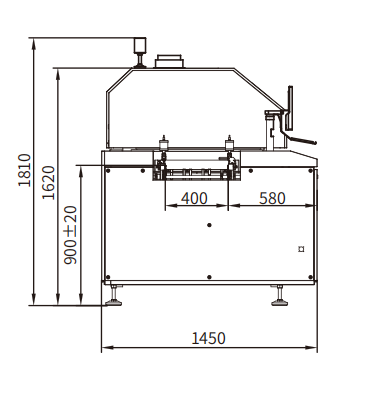

| Conveyor belt height | 900±20mm | ||

| Fixed Rail Side | |||

| Conveyor Type | Chain + mesh with synchronous conveying | ||

| Cmponent Height | +30mm-25mm/Clearance above 30mm,Clearance below 25mm | ||

| Conveying Speed | 300mm-2000mm/min | ||

| Control System | |||

| Power Supply | AC30 5W 380V 50/60HZ | ||

| Total Power | 57KW | 71KW | 89KW |

| Start UP Power | 30KW | 35KW | 40KW |

| Running Power | 7.5KW | 9.5KW | 11.5KW |

| Temperature Range | Room temperature 320℃ | ||

| Control type | PC+PLC Control System | ||

| Rail Width Adjusting Mode | Electric+Manual | ||

| Temp Control Accuracy | ±1℃ | ||

| PCB Temp Deviation | ±1℃ | ||

| Data Storage | Process Data and status record | ||

| Power Outage Protection | Equipped with UPS | ||

| Operation Interface | Windows Chinese simplified,English online free switching | ||

| General | |||

| Dimension(L*W*H) | 5580*1450*1620mm | 6300*1450*1620mm | 7020*1450*1620mm |

| Weight | 2300-2500KG | 2700-2900KG | 3100-3300KG |

| Color | Bright wrinkled white | ||

Modular structure for easy cleaning and maintenance. The front and rear air return design can effectively prevent the influence of airflow between the temperature zones and ensure accurate temperature control. Long life high performance hot air motor. Inverter control, hot air motor can be adjusted at high speed.

Manual + electric width adjustment structure design, equipped with emergency manual transmission structure to prevent power failure from burning out the PCB in the chamber

High stability control system with powerful functions

Special width adjustment and transmission structure design ensures stable and reliable PCB transmission, and the chain adopts anti-jamming plate chain.