YUSH Electronic Technology Co.,Ltd |

|

Verified Suppliers

|

|

500 X 460 (Mm) Pcb Size High Quality Selective Soldering Flux Spray Module/Reflow Oven

Specification:

MODEL | YSF4/46 | YSS4/46 | |

Equipment parameters | Dimension(L×W×H) | 950 x 1776 x 1565 (mm) | 1700 x 1776 x 1565 (mm) |

Transport Parameters | Transport width adjustment | 50-460 (mm) | 50-460 (mm) |

PCB size | 500 x 460 (mm) | 500 x 460 (mm) | |

Conveyor height | 900±20(mm) | ||

The soldering system | Solder pot | electromagnetic pump tin solder pot | |

The amount of tin dross | 0.5KG/pot/week x1 | ||

Nitrogen consumption | 1.5-2m³/h/potx1 | ||

solder pot numbers | single pot/dual pots/dual pots individual control | ||

Introduction:

The spray head which is imported from Germany offers an absolutely

precise and well defined flux deposition on even the smallest

areas. The flux is targeted to beapplied only to the solder

joint,whereby the wettable area can be as small as 3mm.with the

effect that ionic contamination is minimized and flux consumption

is duced.

Features:

Saving 90%flux compared to traditional mode. The wettable area can

be as small as 3mm, minimize the effect of ionic contamination,

meanwhile boards cleaning free. Two axis servo motor control, high

positioning accuracy. Minimum ionic contamination.

Specifications: | |

Flux module x axis distance (max.) | 510mm |

Flux module y axis distance (max.) | 450mm |

Max. nozzle speed | 7m/min |

Flux content | 2 L |

Flux type | RO, RE and OR and with the effective standard of L0, L1, M0,

according to IEC 61190-1-1 |

Flux effective level | L0, L1, M0 |

Nozzle | 130 μm, alternative diameter |

Spray pressure | 0.5~1.0 bar |

Spray width | 2~8 mm (with spray nozzle 130 μm) |

Spray speed | 20 mm/s |

Positioning speed | 400 mm/s |

Positioning accuracy | ±0.2 mm |

Flux system | 2-axis With Servo Drive |

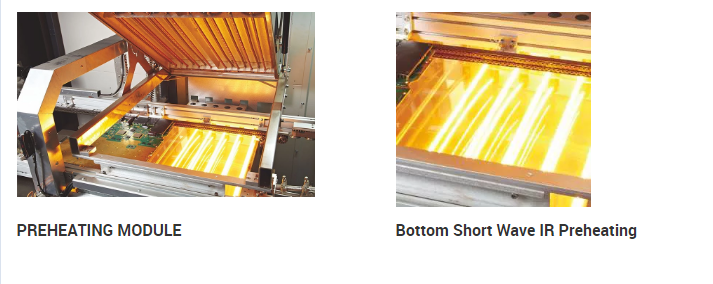

Introduction:

The current selective soldering processes, in particular those for

lead-free soldering, multi-layer boards or high mass components,

call for increased preheat capacities. Short wave IR heater on the

bottom and hot air convective preheating on the top, toensure

preheating evenly.

Features:

1, Segmented & modular layout, preheating more flexibly.

2, Lower short wave IR preheating on the bottom,increasing the

efficiency.

3, Hot air convection preheating on the top, preheating more evenly

(optional).

Top heater power | 4KW |

Top heater voltage | 220V |

Bottom heater powerr | 4.8KW |

Bottom heater voltage | 220V |

CDA pressure | 0.5-0.7MPa |

Advantages Of Using Induction Pump:

1,3-axis servo drives, high control precision.

2,Min.nozzle diameter is 3mm,point or track soldering available

according to different through hole components.

3,Max.solder wave height is 5mm and controllable,soldering climb

rate increased largely.

4,Dual-pot optional, highest flexible.

5,Nitrogen protection, only minute amounts of dross.

6,Pot temperature are continuously monitored.

7,Wave height monitoring available.

8,Solder level monitoring available.

9,No mechanical movement and no wearing.

Specifications: | |

Solder nozzle position | Middle |

Solder content | 13 Kg |

Max. soldering temperature | 350 °C |

Min. internal diameter of solder nozzle | 3 mm, External Diameter 4.5 mm |

Max. Solder wave height | 5 mm |

Soldering speed X,Y-axis | 10 mm/s |

Positioning speed X,Y-axis | 200 mm/s |

Positioning speed Z-axis | 100 mm/s |

Positioning accuracy | ±0.15 mm |

Max.solder distance(x axis) | 510mm |

Max.solder distance(y axis) | 460mm |

Max.distance of z-axis | 58mm |

Max.pot moving speed | 5.8m/min |

Control system | 3-axis With Servo Drive |