Shenzhen Passional Technology Co.,Ltd |

|

Verified Suppliers

|

|

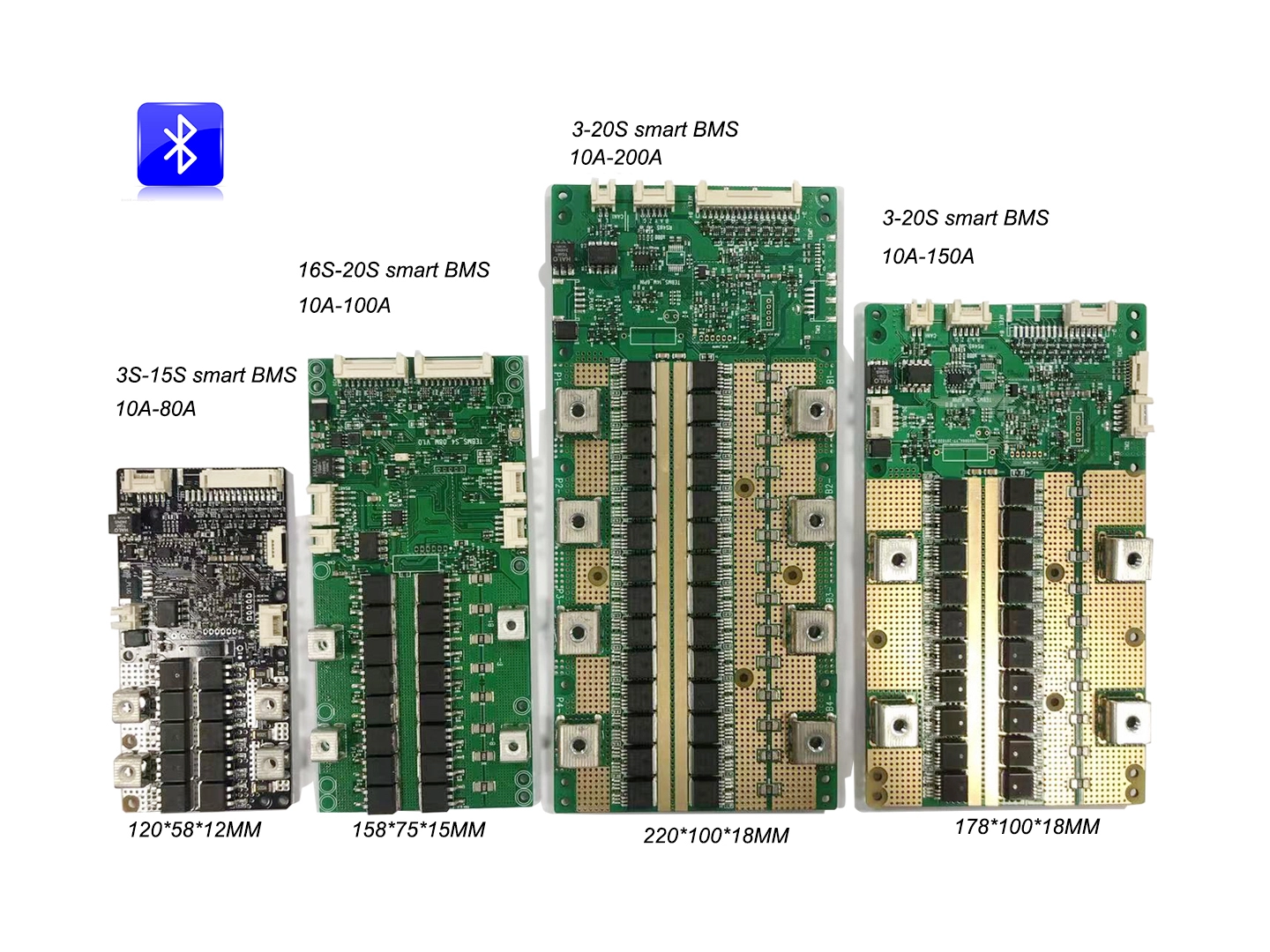

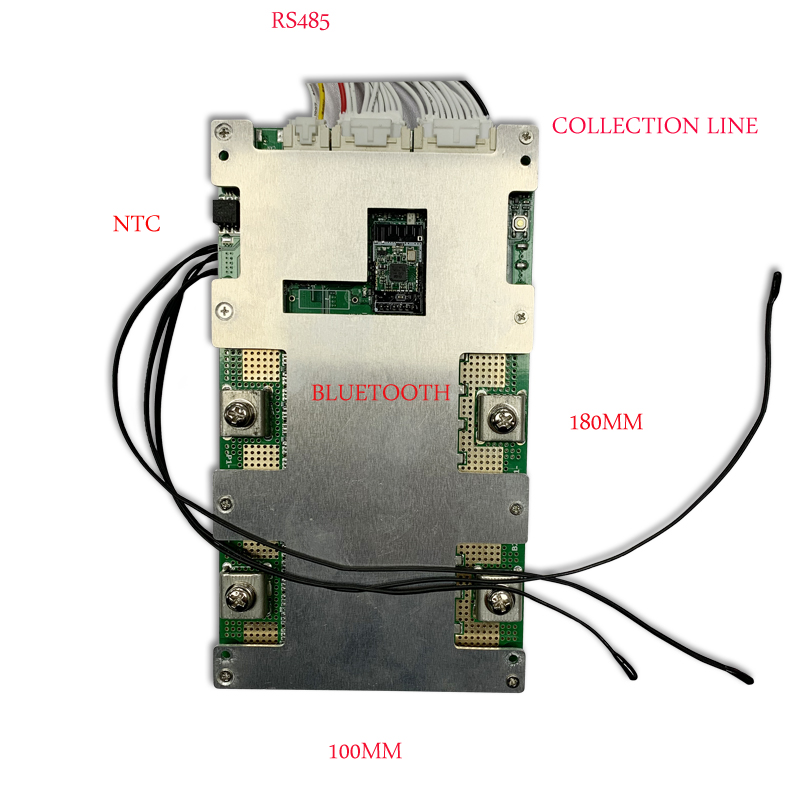

RS485 Smart BMS Battery 20S 72V 10A 50A 80A 100A 200A

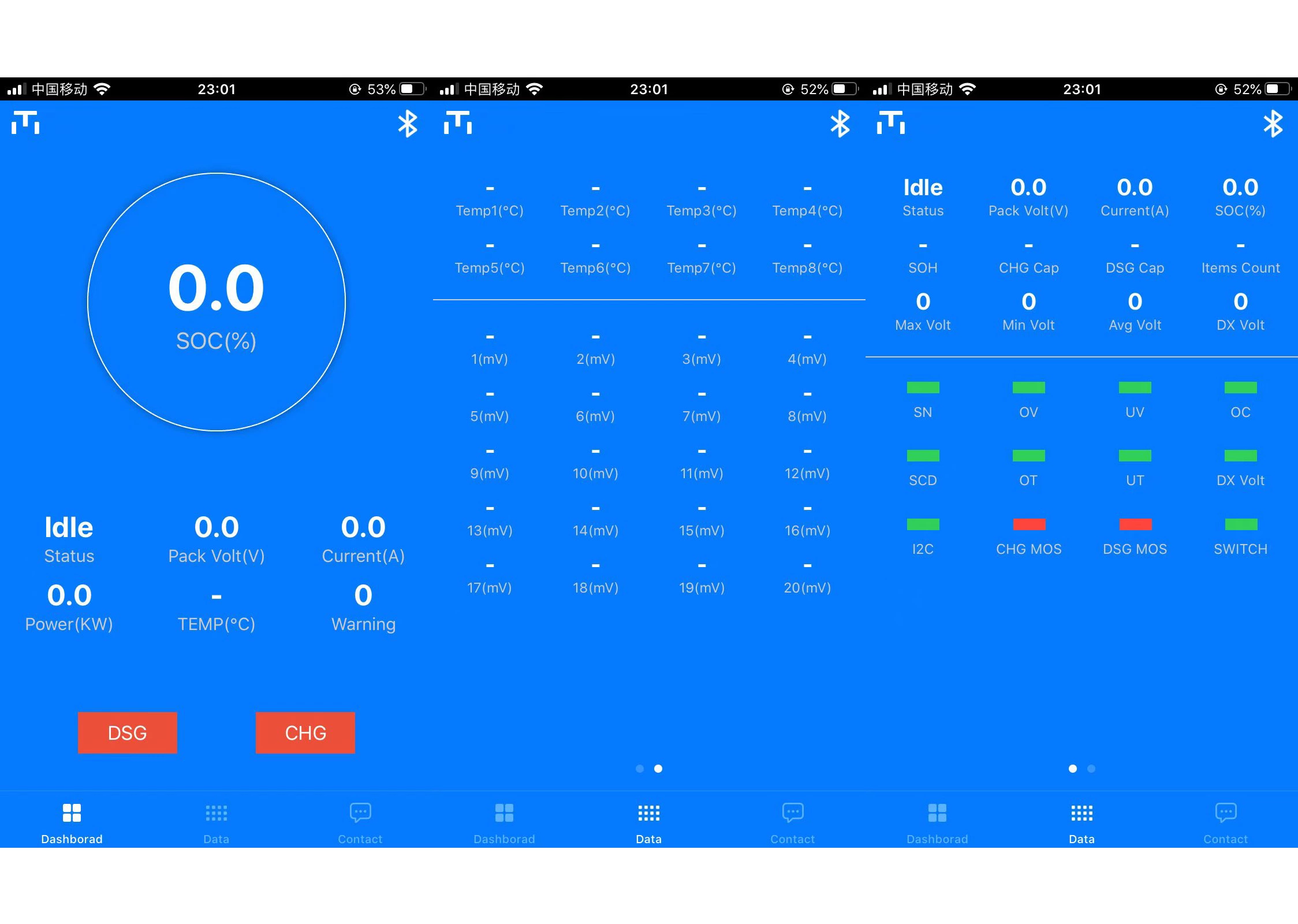

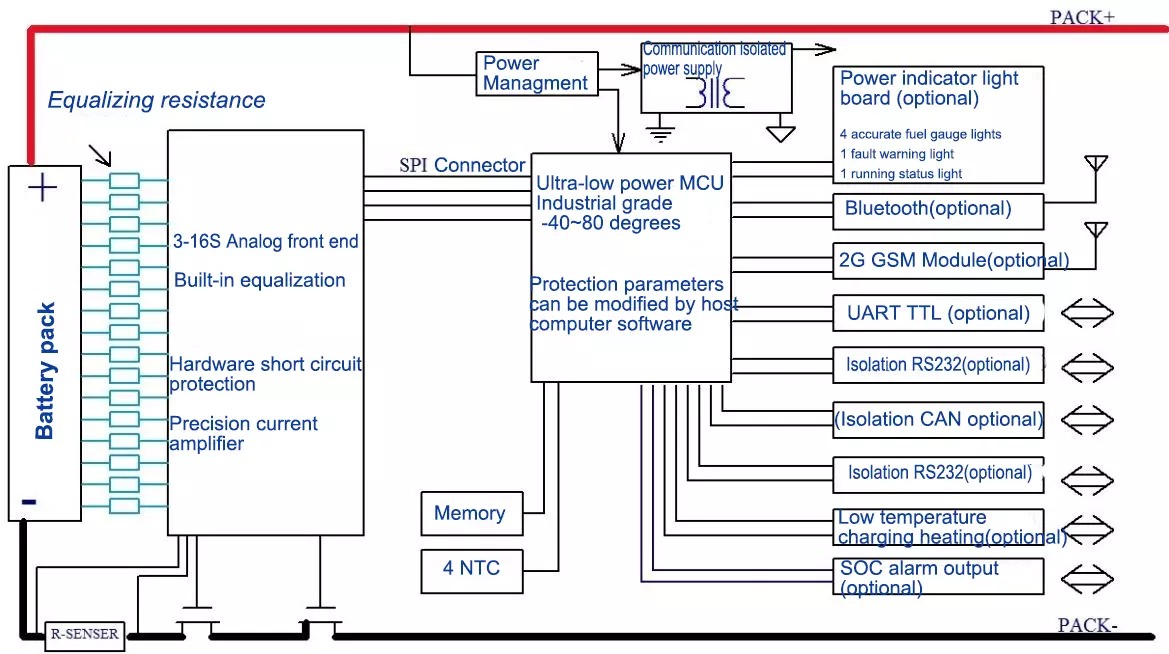

Smart BMS Battery Description:

Battery protection board, as the name suggests, lithium battery protection board is mainly an integrated circuit board that protects rechargeable batteries (usually lithium batteries). The reason why lithium batteries (rechargeable) need protection is determined by their own characteristics. Because the material of the lithium battery itself determines that it cannot be overcharged, overdischarged, overcurrent, short-circuited, or ultra-high temperature charge and discharge. The three basic functions of the lithium battery protection board are short circuit protection, overcharge protection and overdischarge protection.

Smart BMS Battery Parameter:

Content | Specification | Unit | |

Discharge | Continuous Discharge current | 80 | A |

Pluse Discharge Current | 240±20 | A | |

Charge | Charge cut-off voltage | 54.6 | V |

Max charge current | 30(MAX) | A | |

Over Charge protection | Overcharge detection voltage | 4.25±0.05 | V |

Overcharge detection delay time | 600±300 | MS | |

Overcharge release voltage | 4.15±0.05 | V | |

Balance Portection | Balance Detection voltage | 4.18 | V |

Balance release detection voltage | 4.18 | V | |

Balance current | 35±5 | mA | |

Overdischarge Portection | Overdischarge detection voltage | 2.7±0.05 | V |

Overdischarge detection delay time | 600±300 | MS | |

Overdischarge release voltage | 3.0±0.05 | V | |

Overcurrent Portection | Overcurrent detection voltage | 100 | mV |

Overcurrent protection current | 135±20 | A | |

Overcurrent detection delay time | 600±300 | MS | |

Release condition | Cut short load | ||

Short Protection | Detection condition | Out load short cycles | |

Detection delay time | 300±100 | uS | |

Release condition | Cut load |

| |

Temp. protection | Over Charge protection temp. | -20~50 | ℃ |

Over Disharge protection temp. | -20~70 | ||

Interior resistance | Main loop electrify resistance | ≤10 | mΩ |

Current consumption | Current consume in normal operation | ≤100 | uA |

Sleep current(over discharge) | ≤20 | uA | |

Working Temp. | Temp.range | -20/80 | ℃ |

How to choose the right BMS board?

1. Determine your battery type (ternary/NCM, lithium iron/LFP,

lithium titanate/LTO) and determine

The number of strings and parallels of the battery pack. Choose

according to the number of concatenations.

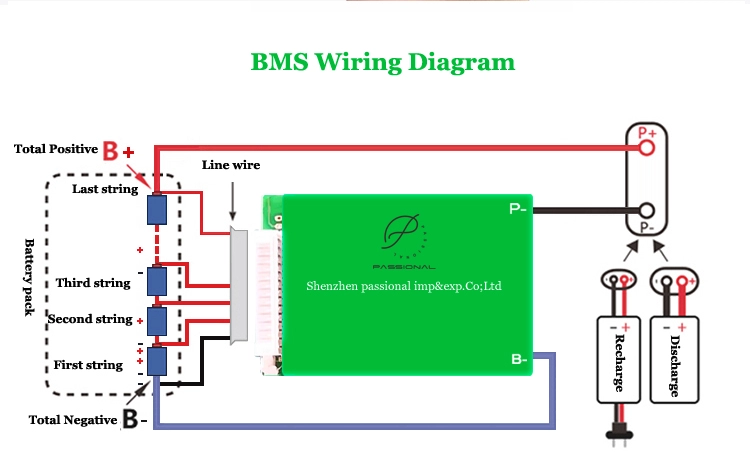

2. Determine whether the battery pack is charged and discharged in

the same port or in different ports. The charging and discharging

of the same port is the same line, but a separate port is an

independent charging and discharging line.

3. Determine the current value required by the protection board:

I=P/U. That is, current = power/voltage. . Remember that this is

only a theoretical value. In fact. We use this theoretical value as

a reference. Taking into account the load, uphill and just starting

environment, generally two-wheeled electric vehicles choose more

than 2 times the theoretical value. Three-wheeled electric vehicles

choose more than 3 times this theoretical value. Four-wheel

low-speed vehicles generally have about 3.5 times. For inverters

and energy storage products, 1.2 times is enough. Or refer to the

current limit of the electric vehicle controller. ensure. The

current value of the guard plate must be greater than the control

current limit value.