Hangzhou Chenrui Air Separator Installation Manufacture Co. Ltd |

|

High Purity PSA Nitrogen Generator , Pressure Swing Adsorption Nitrogen Generation

Product Description

| Specification | output (Nm³/h) | Effective gas consumption (Nm³/h) | air cleaning system | Importers caliber | |

| CBN-5A | 5 | 0.76 | KJ-1 | DN25 | DN15 |

| CBN-10A | 10 | 1.73 | KJ-2 | DN25 | DN15 |

| CBN-20A | 20 | 3.5 | KJ-6 | DN40 | DN15 |

| CBN-30A | 30 | 5.3 | KJ-6 | DN40 | DN25 |

| CBN-40A | 40 | 7 | KJ-10 | DN50 | DN25 |

| CBN-50A | 50 | 8.6 | KJ-10 | DN50 | DN25 |

| CBN-60A | 60 | 10.4 | KJ-12 | DN50 | DN32 |

| CBN-80A | 80 | 13.7 | KJ-20 | DN65 | DN40 |

| CBN-100A | 100 | 17.5 | KJ-20 | DN65 | DN40 |

| CBN-150A | 150 | 26.5 | KJ-30 | DN80 | DN40 |

| CBN-200A | 200 | 35.5 | KJ-40 | DN100 | DN50 |

| CBN-300A | 300 | 52.5 | KJ-60 | DN125 | DN50 |

Applications

- Food packaging (cheese, salami, coffee, dried fruit, herbs,

fresh pasta, ready meals, sandwiches,etc. ..)

- Bottling wine, oil, water, vinegar

- Fruit and vegetable storage and packing material

- Industry

- Medical

- Chemistry

PSA Nitrogen Generator System is used worldwide.

Principle of Operation

The oxygen and nitrogen generators are constructed according to the

principle of operation P.S.A. (Pressure Swing Adsorption) and are

composed by a minimum of two absorbers filled up with molecular

sieve.The absorbers are crossed alternatively by the compressed air

(previously purified in order to eliminate oil, humidity and

powders) and produce nitrogen or oxygen. While a container, crossed

by the compressed air, produces gas, the other regenerates itself

losing to pressure atmosphere the gases previously adsorbed. The

process comes repeated in cyclical way. The generators are managed

by a PLC.

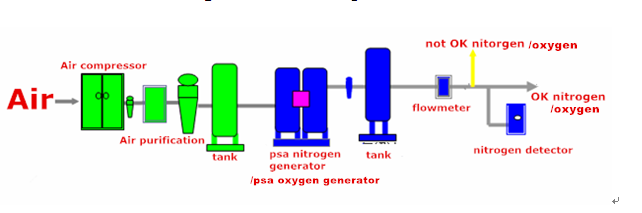

Process Flow Brief Description

Technical Features

1). Full Automation

All systems are designed for un-attended operation and automatic

Nitrogen demand adjustment.

2). Lower Space Requirement

The design and Instrument makes the plant size very

compact,assembly on skids,prefabricated from factory.

3). Fast Start-up

Start-up time is only 5 minutes to get desired Nitrogen purity.So

these units can be switched ON&OFF as per Nitrogen demand

changes.

4). High Reliabiity

Very reliable for continuous and steady operation with constant

Nitrogen purity.Plant availability time is better than 99% always.

5). Molecular Sieves life

Expected Molecular sieves life is around 15-years i.e. whole life

time of nitrogen plant.So no replacement costs.

6). Adjustable

By altering flow,you can deliver nitrogen with precisely the right

purity.

Service Commitment

1. When receiving debugging information from our customers in the debug phase, we will arrive to the site in 48 hours if the debugging condition limited.

2. When the machine in operation, if you have any questions, please turn to our after-sales for help: 15088601709. We will provide you with reasonable suggestions and help them to solve the problems.

3. To the customers who need to change the accessories, we will send to you as soon as possible.

4. Any operational problems with the machine, we will arrive the site in 24 hours.

5. Any dissatisfaction with our after-sale services, please call our complains hotline:0571-63492003

FAQ

1. Are you manufacturer or Trade Company?

We are the manufacturer of nitrogen Generator, founded in 2005

2. What's the order nitrogen generator process?

a. Inquiry---provide us all clear requirements.

b. Quotation---official quotation form with all clear

specifications.

c. Printing file--- PDF, Ai, CDR, PSD, the picture resolution must

be at least 300 dpi.

d. Contract confirmation---provide correct contract details.

e. Payment terms--- Negotiable.

f. Production---mass production

g. Shipping--- by sea, air or courier. Detailed picture of package

will be provided.

h. Installation and commissioning

3. What terms of payment you use?

T/T, L/C etc.

4. How to get a prompt quotation of nitrogen Generator?

When you send the inquiry to us, pls kindly send it with below

technical information.

1) N2 flow rate: _____Nm3/hr( or How many cylinders do you

want to fill per day(24hours))

2) N2 purity: _____%

3) N2 discharge pressure: _____Bar

4) Voltages and Frequency : ______V/PH/HZ

5) Application:

6) Project Location: